Assembly tooling and assembly method of timing chain system of engine

An assembly tooling and engine technology, applied in metal processing, manufacturing tools, workpiece clamping devices, etc., can solve the problems of unfavorable parts counting and management, large labor consumption, slow production cycle, etc., to improve assembly efficiency and assembly quality , Reduce labor load and labor intensity, and facilitate management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

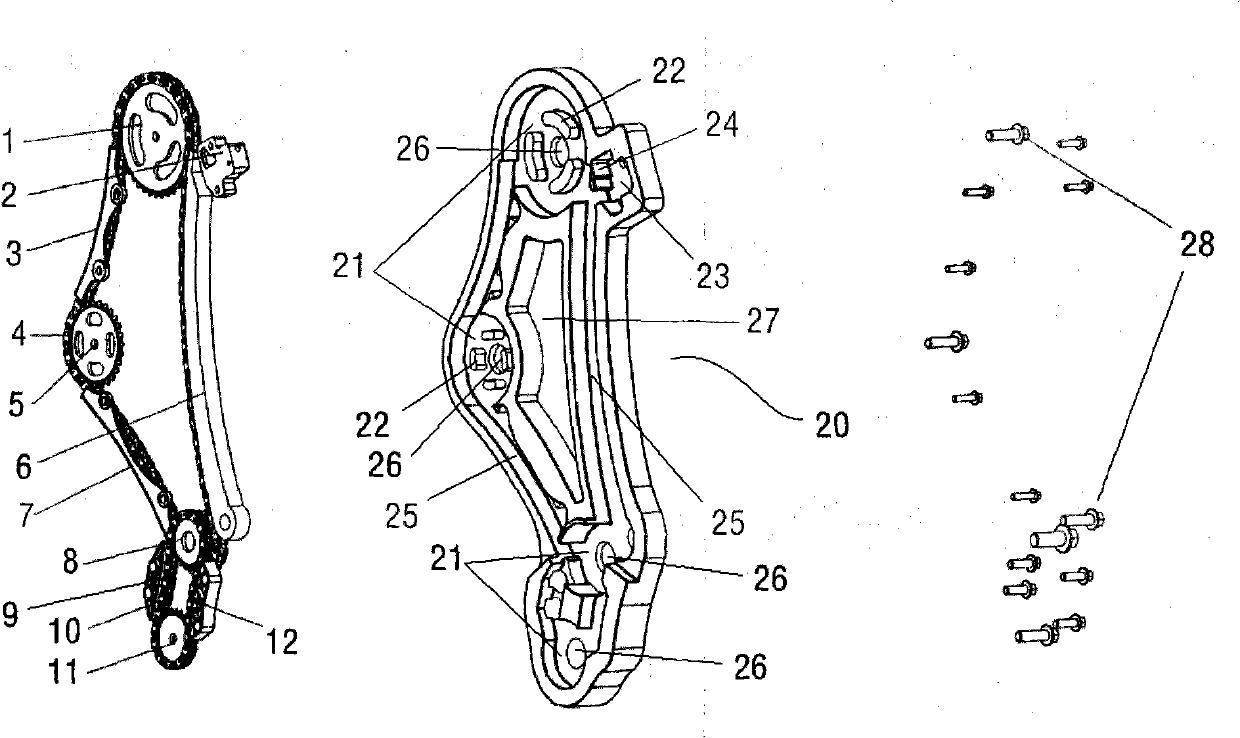

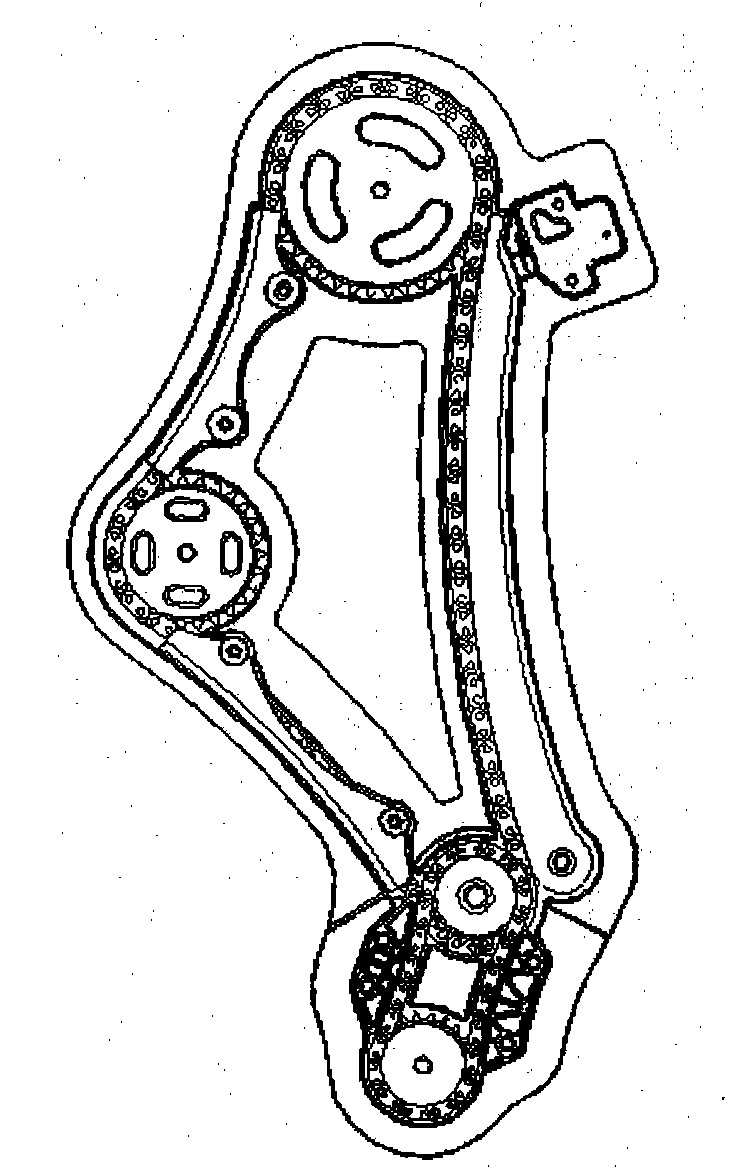

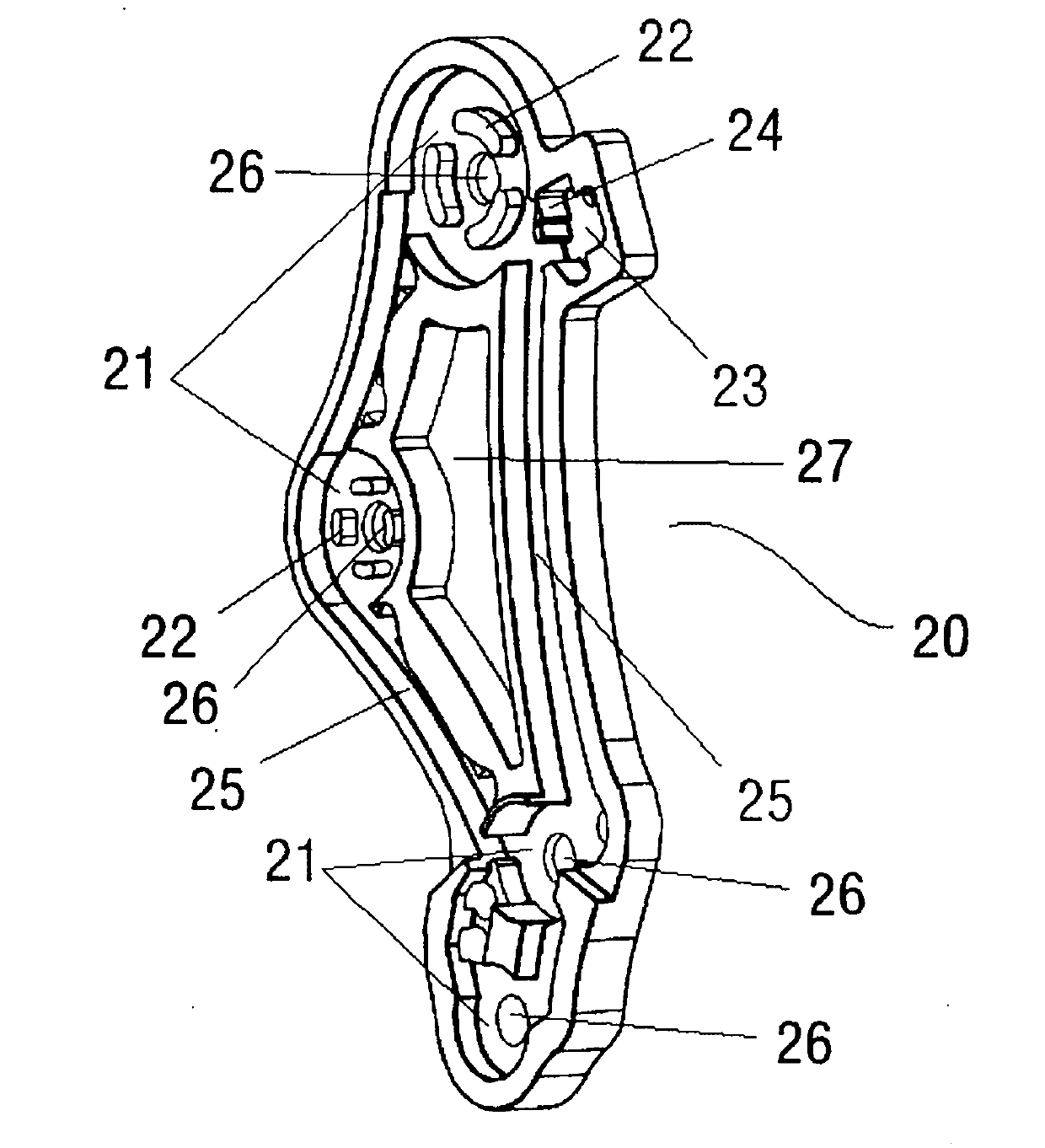

[0022] Such as figure 1 As shown, the assembly tooling 20 of the engine timing chain system of this embodiment is made of plastic injection molding, and its shape is consistent with the shape of the assembled timing chain system. The tooling 20 is set at the position corresponding to each component of the timing chain system There are limited recesses, the back of the tooling 20 is provided with through holes with a diameter larger than the diameter of the mounting bolts at the positions corresponding to the mounting holes of each component, and the tooling 20 is provided with through holes with a diameter slightly larger than the shaft holes at the positions corresponding to the shaft holes of each sprocket.

[0023] Such as figure 1 , 2 As shown, specifically:

[0024] The tooling 20 is provided with a limit recess 21 with a profile slightly larger than the diameter of the above-mentioned sprocket at the positions corresponding to the camshaft sprocket 1, the crank sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com