Dual-alloy cladding layer wear plate and preparation method

A technology of spectacle plates and cladding layers, which is applied in the direction of mechanical equipment, liquid fuel engines, and parts of pumping devices for elastic fluids, etc. It can solve the problems of high material costs, thermal shock of hard alloys, and inability to meet actual needs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

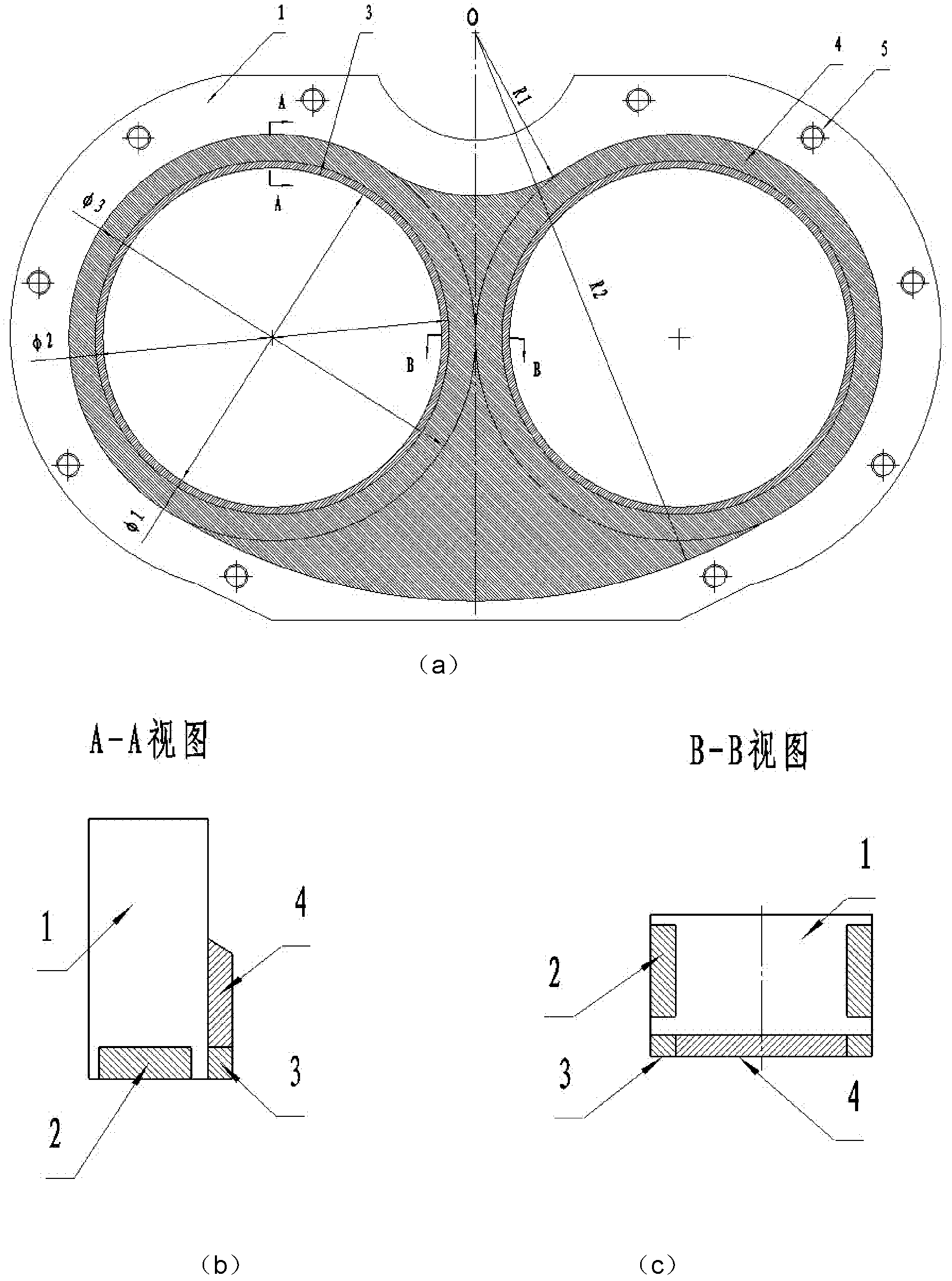

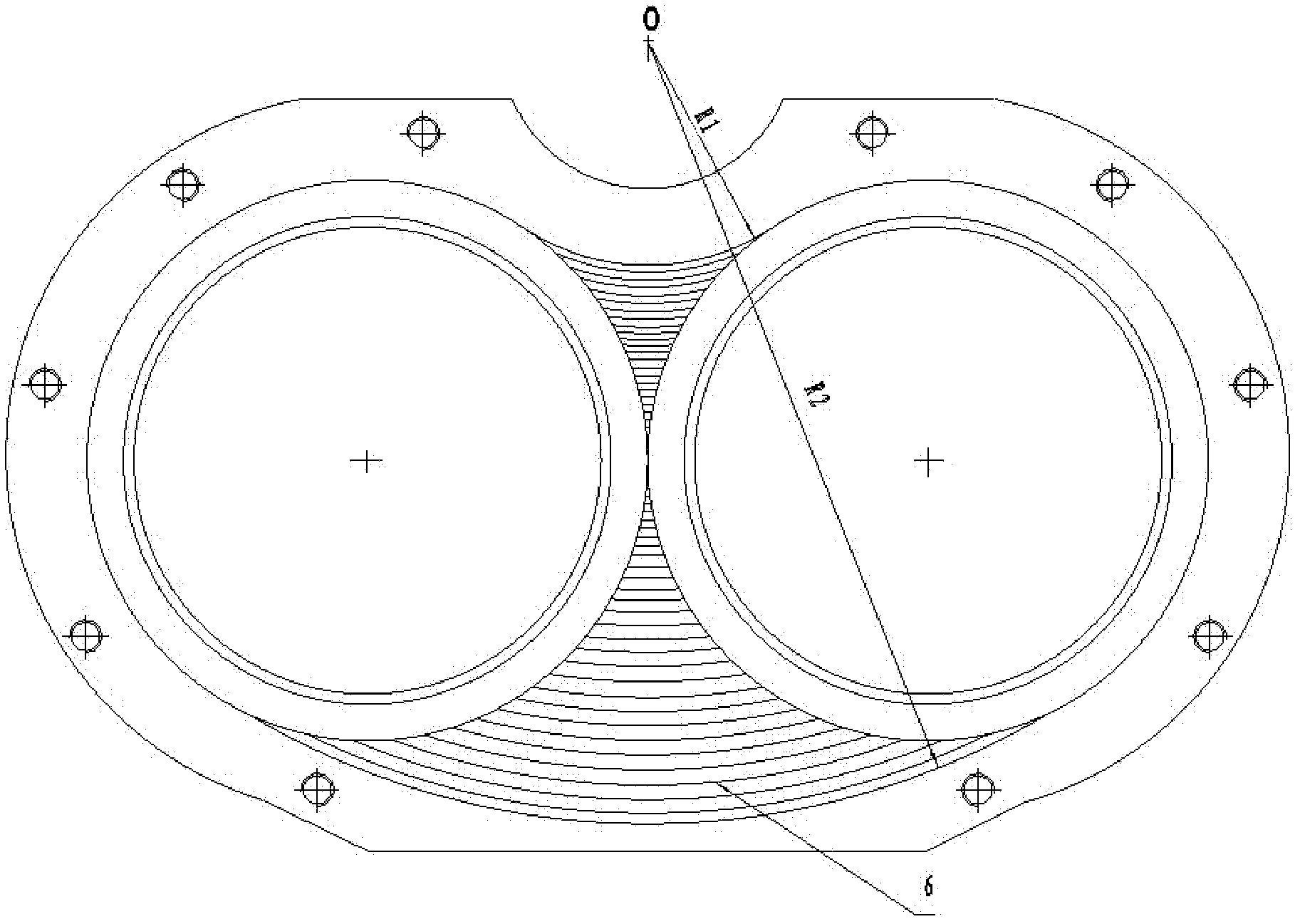

[0022] (1) Select 35 steel as the base material of the spectacle plate, and obtain a high-precision spectacle plate base (the outer contour of the spectacle plate and two holes cut) by laser cutting according to the drawing, and the thickness of the base is 30mm;

[0023] (2) Machining the substrate of the spectacle plate, reserve a subsequent cladding thickness of 3.0mm on the inner surface of the two holes of the spectacle plate, and process the mounting holes of the spectacle plate.

[0024] (3) Laser cladding equipment adopts Trumpf 6000 watts CO 2 Laser (wavelength 10.6um), coaxial cladding head, double-barrel powder feeder, one of which is filled with iron-based alloy powder, and the other is filled with nickel-tungsten carbide powder. The chemical composition of the iron-based alloy used is C: 0.70 wt%, B: 3.0 wt%, Cr: 24 wt%, Ni: 7 wt%, Si: 3.0 wt%, and the balance Fe. The chemical composition of the nickel-tungsten alloy used is C: 2.7 wt%, Cr: 13 wt%, Si: 2.8 wt%, W...

Embodiment 2

[0033] (1) Select 45 steel as the base material of the spectacle plate, and obtain a high-precision spectacle plate base (the outer contour of the spectacle plate and two holes cut) by laser cutting according to the drawing, and the thickness of the base is 30mm;

[0034] (2) Machining the substrate of the spectacle plate, reserve a subsequent cladding thickness of 3.0mm on the inner surface of the two holes of the spectacle plate, and process the mounting holes of the spectacle plate.

[0035] (3) The laser cladding equipment adopts a 4000-watt optical fiber output semiconductor laser (wavelength 1070nm), a coaxial cladding head, and a double-barrel powder feeder, one of which is filled with iron-based alloy powder, and the other is filled with nickel-tungsten carbide powder. The chemical composition of the iron-based alloy used is C: 0.55 wt%, B: 2.5 wt%, Cr: 22 wt%, Ni: 5.5%, Si: 2.4 wt%, and the balance Fe. The chemical composition of the nickel-tungsten alloy used is C: ...

Embodiment 3

[0044] (1) Select 45 steel as the base material of the spectacle plate, and obtain a high-precision spectacle plate base (the outer contour of the spectacle plate and two holes cut) by laser cutting according to the drawing, and the thickness of the base is 30mm;

[0045] (2) Machining the substrate of the spectacle plate, reserve a subsequent cladding thickness of 3.0mm on the inner surface of the two holes of the spectacle plate, and process the mounting holes of the spectacle plate.

[0046] (3) Laser cladding equipment adopts 3000 watts of optical fiber output semiconductor laser (wavelength 808-975nm), coaxial cladding head, double-barrel powder feeder, one of which is filled with iron-based alloy powder, and the other is filled with nickel-tungsten hard quality alloy powder. The chemical composition of the iron-based alloy used is C: 0.40 wt%, B: 2.0 wt%, Cr: 20 wt%, Ni: 4%, Si: 1.8 wt%, and the balance Fe. The chemical composition of the nickel-tungsten alloy used is C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com