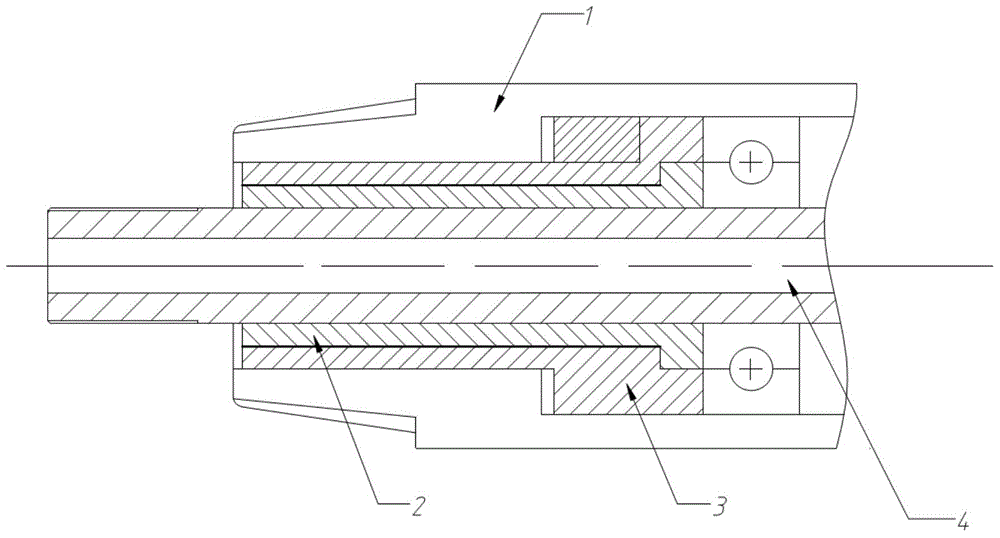

A kind of manufacturing method of radial bearing of screw drilling tool

A technology for radial bearings and manufacturing methods, which is applied in the field of radial bearings of screw drilling tools and laser cladding surfaces, can solve problems such as peeling off of hard blocks and uneven wear of radial bearings, and achieve improved service life, uniform wear, and metallurgical good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

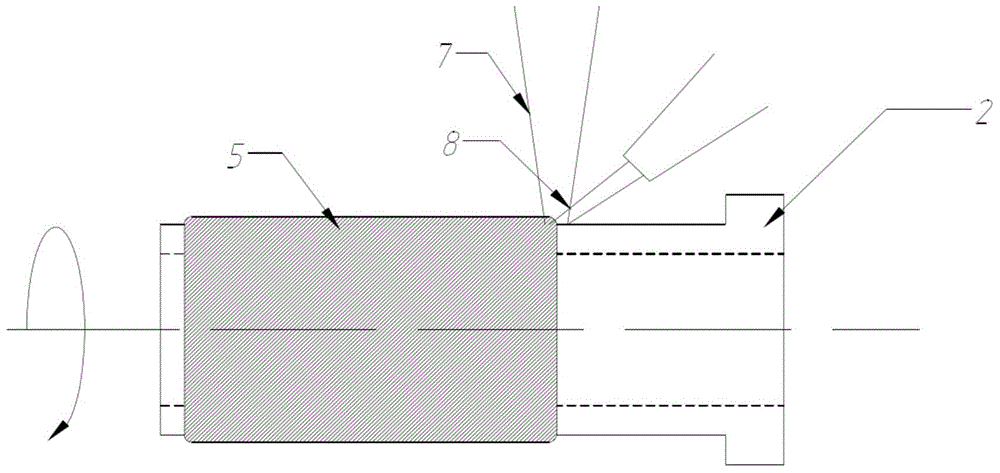

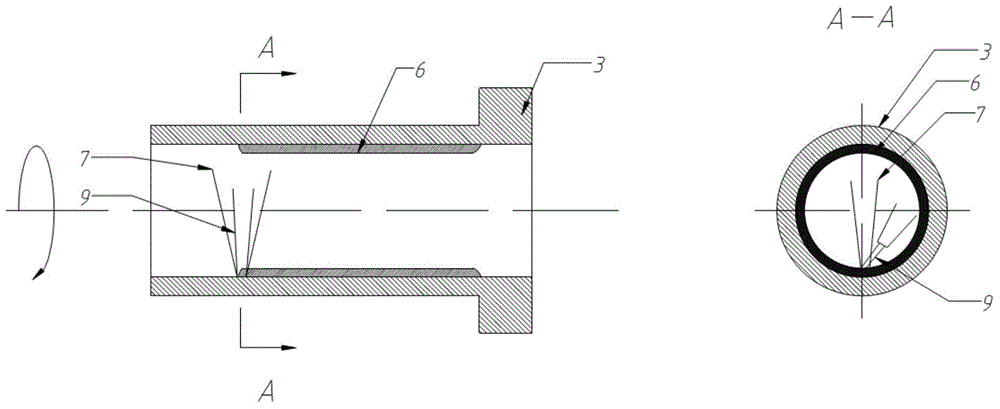

[0017] (1) Select the 42CrMo cylindrical steel body to be blanked as a rigid body blank, and hot forge the rigid body blank to complete the rough machining of both end faces, outer diameter, inner diameter and chamfering of the rigid body blank. After processing, the bearing steel body is heat treated.

[0018] (2) Laser cladding equipment is Trumpf 6000 watts CO 2 Laser (wavelength 10.6 μm). The material used for the outer circle of the inner shaft sleeve is a Fe-based composite material with a chemical composition of Cr 3 C 2 : 20wt%, WC: 15wt%, Mo: 2.0wt%, Cr: 3wt%, Ni: 2.0wt%, Si: 0.4wt%, Mn: 0.3wt%, Ti: 0.5wt%, the balance Fe.

[0019] The laser cladding output power of the outer circle of the inner shaft sleeve is 4.0KW, the beam scanning speed is 600mm / min, the spot size range is 3mm, the powder feeding volume is 20g / min, the argon gas flow range is 20L / min, and the overlap rate is 50%. . The thickness of the obtained cladding layer is 1.5mm.

[0020] The material...

Embodiment 2

[0027] (1) 45 steel cylindrical steel body is selected as a rigid body blank, and the rigid body blank is subjected to precise thermal rolling and expansion to complete the rough machining of both end faces, outer diameter, inner diameter and chamfering of the rigid body blank. After processing, the bearing steel body is heat treated.

[0028] (2) The laser cladding equipment is a 3000 watt fiber output semiconductor laser (wavelength 808-975nm). The material used for the outer circle of the inner shaft sleeve is a Fe-based composite material with a chemical composition of Cr 3 C 2 : 40wt%, WC: 30wt%, Mo: 5.0wt%, Cr: 6wt%, Ni: 3.0wt%, Si: 0.8wt%, Mn: 0.6wt%, Ti: 1.5wt%, the balance Fe.

[0029] The laser cladding output power of the outer circle of the inner shaft sleeve is 2.0KW, the beam scanning speed is 200mm / min, the spot size range is 6mm, the powder feeding volume is 40g / min, the argon gas flow range is 10L / min, and the overlap rate is 30%. . The thickness of the ob...

Embodiment 3

[0037] (1) Select the 9Cr18 steel cylindrical steel body to be blanked as a rigid body blank, and hot-roll the rigid body blank to complete the rough machining of both end faces, outer diameter, inner diameter and chamfering of the rigid body blank. After processing, the bearing steel body is heat treated.

[0038] (2) The laser cladding equipment is a 4000 watt fiber output semiconductor laser (1070nm). The material used for the outer circle of the inner shaft sleeve is Fe-based composite material, and its chemical composition is Cr 3 C 2 : 30wt%, WC: 20wt%, Mo: 3.0wt%, Cr: 4.0wt%, Ni: 2.5wt%, Si: 0.6wt%, Mn: 0.5wt%, Ti: 1.0wt%, the balance Fe.

[0039] The laser cladding output power of the outer circle of the inner shaft sleeve is 3.0KW, the beam scanning speed is 400mm / min, the spot size range is 4mm, the powder feeding volume is 20g / min, the argon gas flow range is 15L / min, and the overlap rate is 40%. . The thickness of the obtained cladding layer is 2.0mm.

[0040] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com