A self-adjustable crimping wheel device

An automatic adjustment and crimping wheel technology, which is applied in the field of crimping wheel devices, can solve the problems of indentation, scratches, bumps, etc., and achieve the effects of improving utilization rate, service life, shock absorption and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

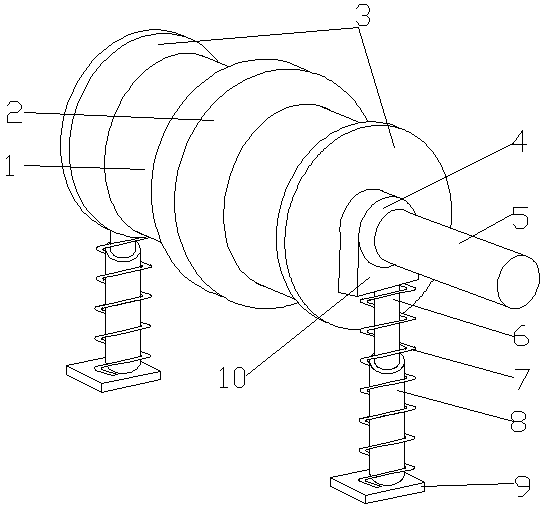

[0019] Such as figure 1 As shown, an automatically adjustable crimping wheel device includes a crimping wheel 1, a bearing 4, a universal joint shaft 5 and an elastic support structure, and both ends of the crimping wheel 1 are fixed with limit baffles 3, The middle part is fixed with a limit partition 2 to separate the crimping wheel 1; one end of the rotating shaft of the crimping wheel 1 is fixedly connected to the universal joint shaft 5, and the universal joint shaft 5 is connected to the drive motor; The elastic support structure includes a support seat 10, a spring 7, a telescopic mechanism and a fixed frame 9, the telescopic mechanism includes a sleeve rod 6 and a sleeve 8, and the outer circumference of the rotating shaft extending from both ends of the crimping wheel 1 is fixed on the On the inner ring of the bearing 4 whose size and shape match the outer circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com