Automatically adjusted line pressing wheel device

An automatic adjustment and crimping wheel technology, which is applied in the field of crimping wheel devices, can solve the problems of indentation, scratches, bumps, etc., and achieve the effects of improving utilization rate, service life, shock absorption and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

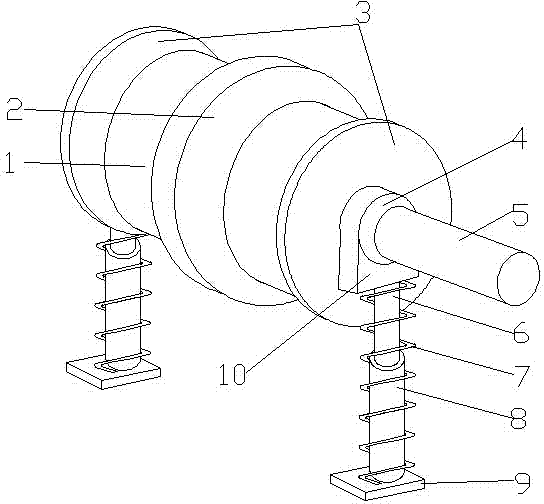

[0018] like figure 1 Show, a automatic regulating wire wheel device, including piercing wires 1, bearing 4, universal bearing 5, and elastic support structure.Ministry of Fixed Limited I amoper to separate the voltage wire 1; one end of the voltage wheel 1 rotation axis is connected to the universal shutdown axis 5, which is connected to the driver's motor;The elastic support structure includes supporting seat 10, spring 7, telescopic mechanism and fixed rack 9, which include the telescopic structure 6 and sleeve 8.The internal ring of the bearing 4, which is matched with the shape of the shaft perimeter, is fixed on the internal ring of the bearing 4, which is fixed on the support seat 10 of the supporting seat.The clog 6 cover is in the lower end of its and matched it with it. The lower end of the support seat is also fixed with a spring 7.And together with the sleeve 8, they are fixed on the fixed rack 9; the voltage wheel 1, limited baffle 3, and limited partition 2 are made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com