Grouting and lapping machine for outer wall insulation boards

A technology for external wall insulation boards and mesh machines, which is applied to ceramic molding machines, manufacturing tools, etc., to achieve the effects of improving uniformity, improving work efficiency, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

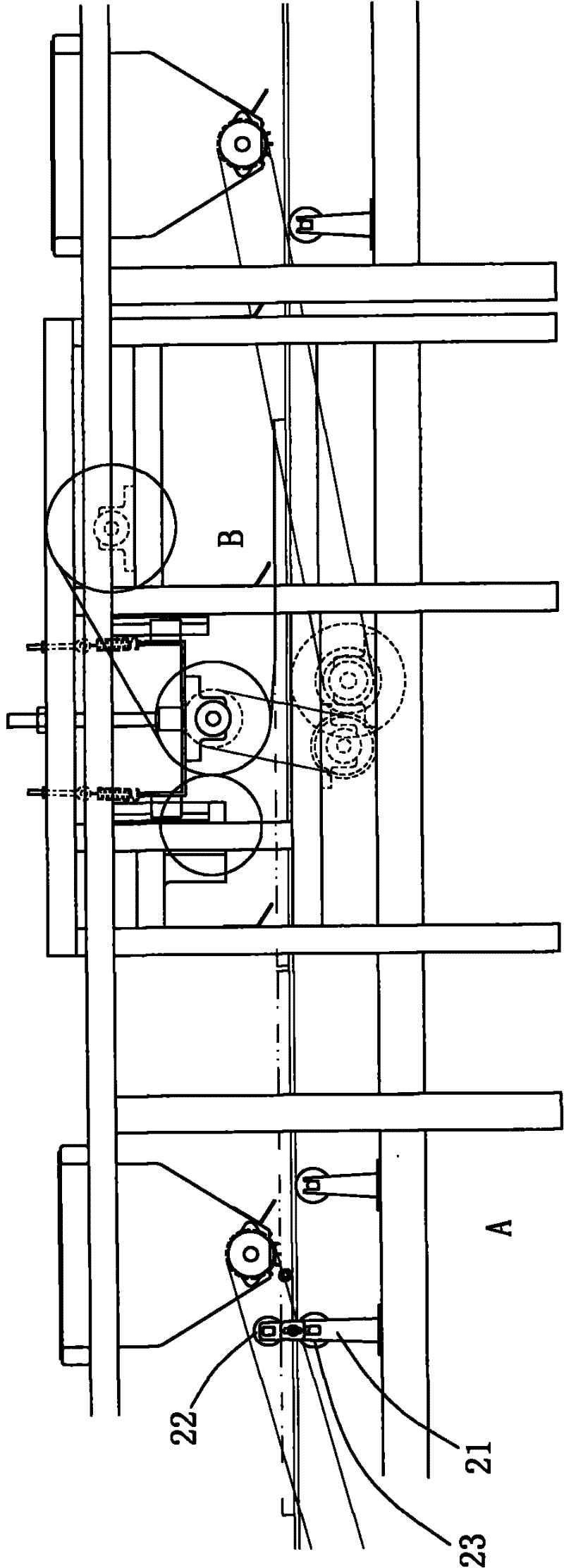

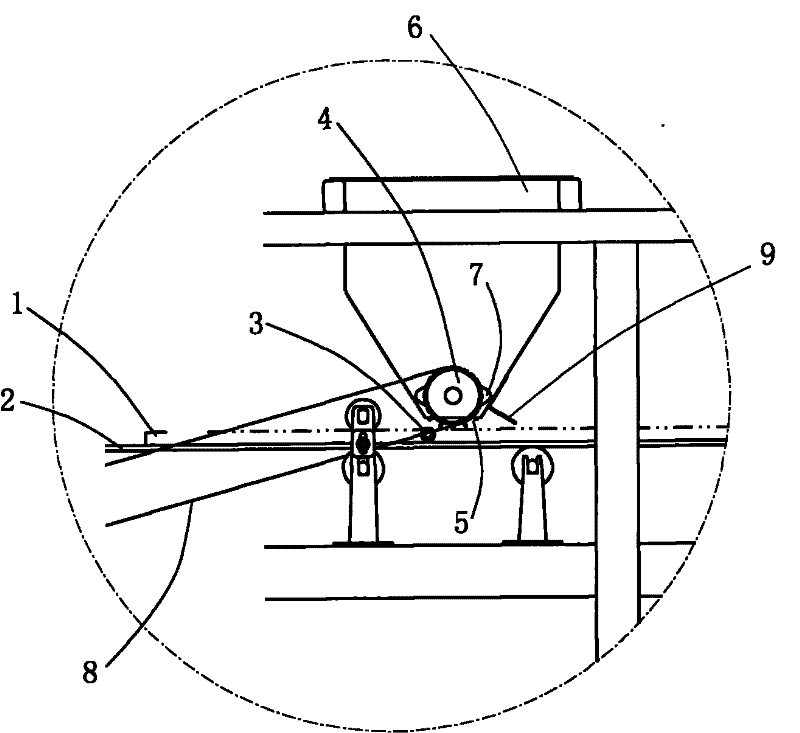

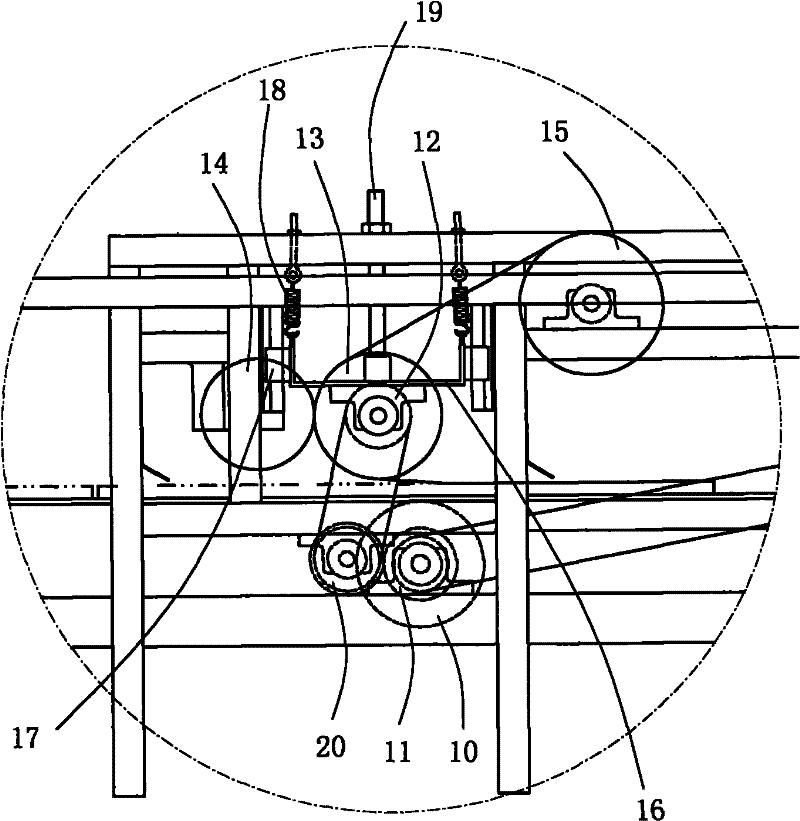

[0022] Example: Combine Figure 1-3 , The sizing net machine on the external wall insulation board, along the forward direction of the workpiece conveyor belt, sets the sizing station, the online station and the second sizing station on the frame in sequence.

[0023] Part A in the figure is the first sizing station. A cement slurry hopper 6 is fixed on the frame above the conveyor belt 2, and a rolling drum 5 is installed at the outlet of the hopper. When the blades and the rolling drum 5 rotated, the cement slurry fell from the gap between the blades, and when the rolling drum 5 was stationary, the discharge port of the blade blocking hopper did not allow the cement slurry to fall. A V-belt pulley 7 and an electromagnetic clutch 4 are arranged coaxially with the material drum 5, and the proximity switch 3 below the hopper inputs electric signals to the electromagnetic clutch 4. When the electromagnetic clutch is turned on, the V-belt pulley 7 drives the material drum 5 to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com