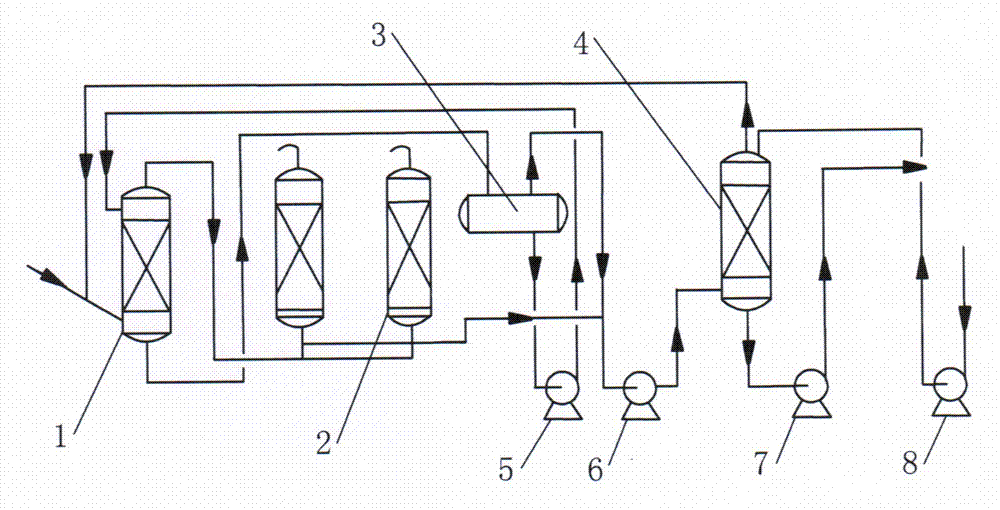

Oil-gas adsorption and absorption technical method

A process method, oil and gas technology, applied in the petroleum industry, separation methods, chemical instruments and methods, etc., can solve the problems of large-scale bad distribution, liquid distributor separation effect is difficult to meet the requirements, etc., to achieve good adjustment ability and equipment utilization rate High, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

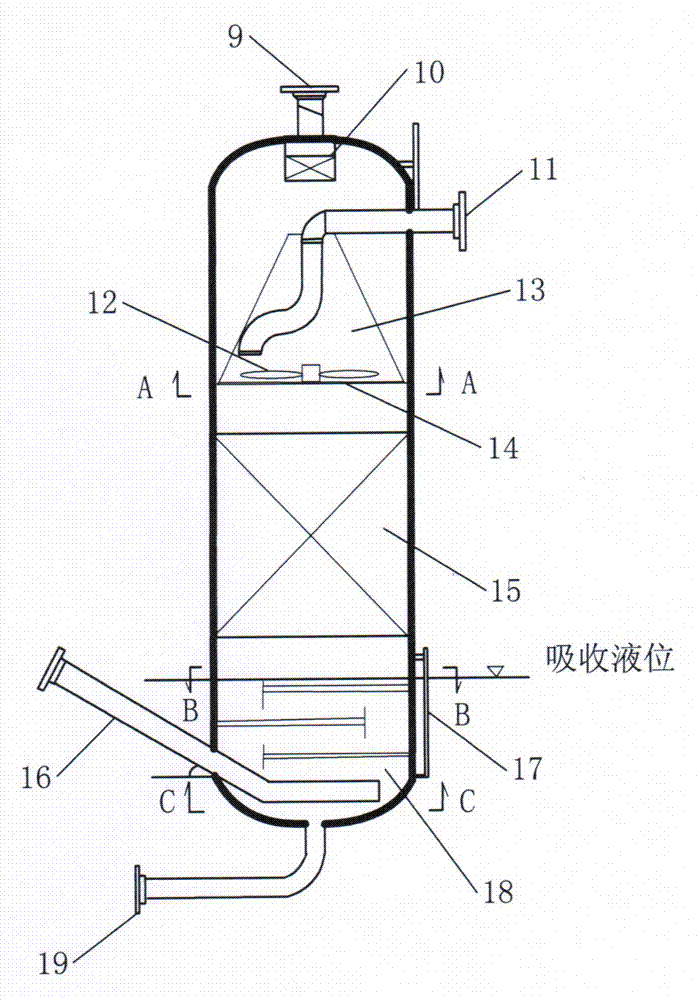

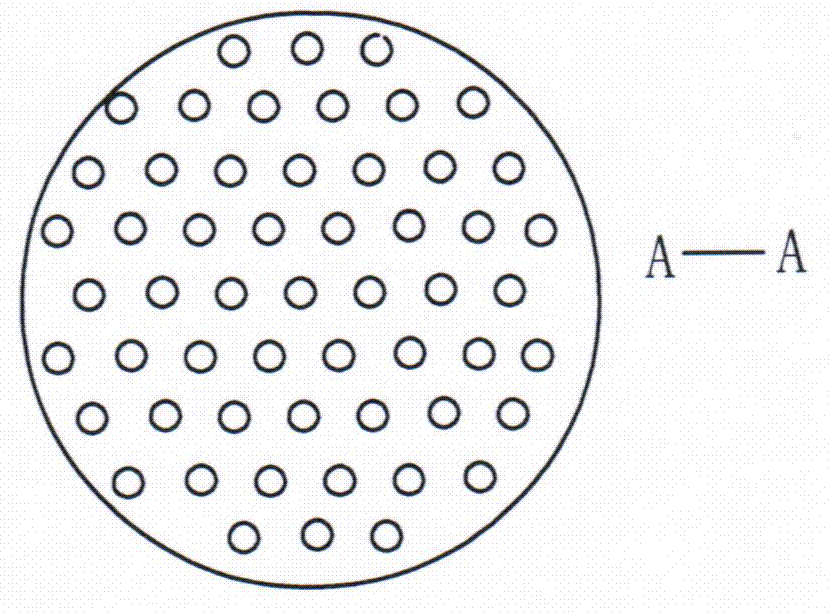

[0050] In this example, the flow rate of the oil gas and air mixture discharged during the storage and transportation of oil products is 300 m 3 / h, the absorption tower diameter is designed to be 80cm. The diameter of the absorbent inlet pipe of the absorption tower is 10cm, connected by an elbow, and its outlet is 16cm away from the center of the tower diameter. The impeller is 6cm below the outlet of the inlet pipe, with a radius of 25cm. The shaft is fixedly connected with the chassis and the conical cover to form a simple fixed axial flow impeller, which converts the flow pressure of the liquid inlet into mechanical kinetic energy and drives the overall rotation of the conical cover of the spray device. . The cone is made of lightweight carbon fiber material and has a height of 50cm. The disc-type hole flow distributor is 100cm away from the top of the tower, the maximum radius of the bottom is 38cm, and there are 50 small overflow holes with a diameter of 32mm, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com