Mini camera module and method for producing the same

The technology of a camera module and its manufacturing method, which is applied in the field of optical imaging, can solve the problems that the camera module is large in size and difficult to integrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

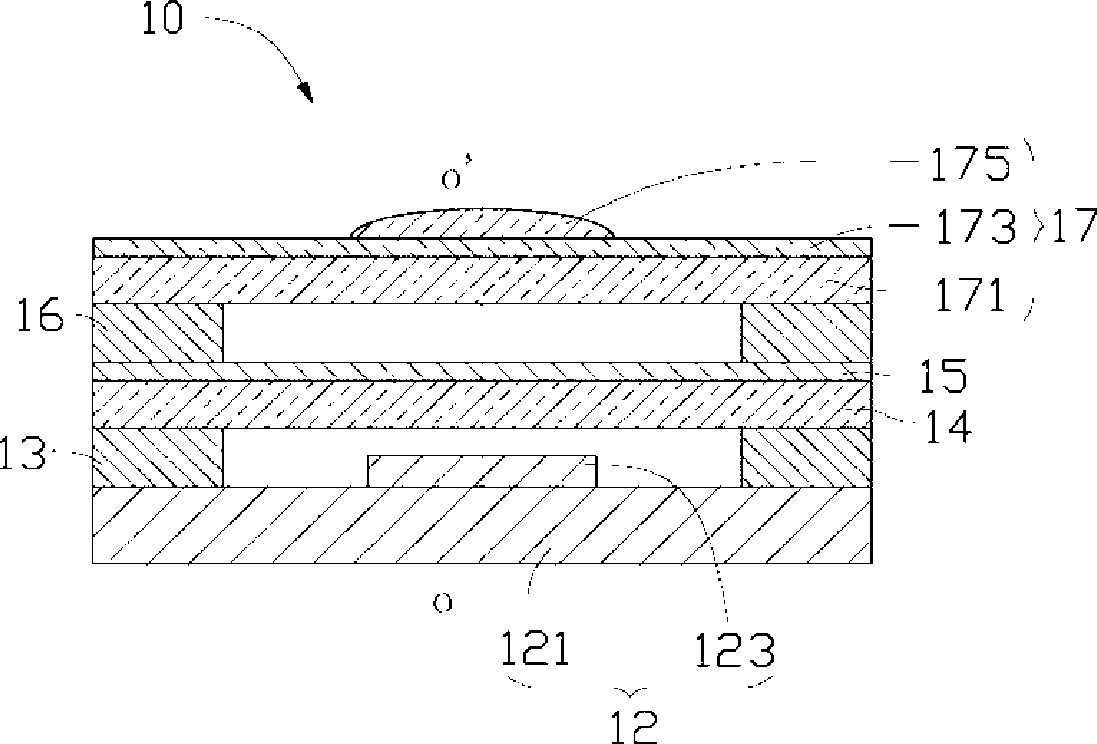

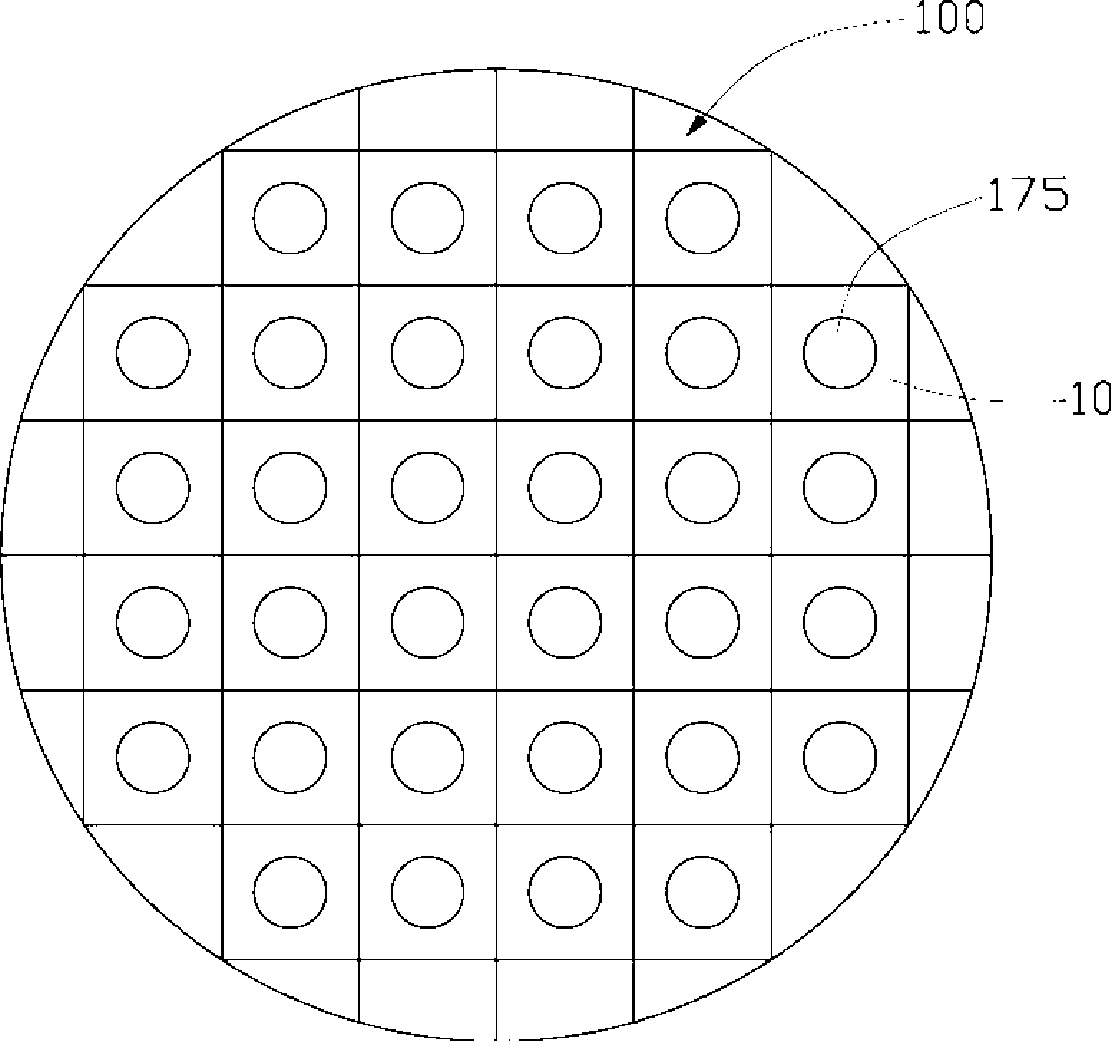

[0022] see figure 1 , the miniature camera module 10 provided by the first embodiment of the present invention includes an image sensing unit 12, a spacer layer 13, a transparent cover plate 14, an infrared cut filter (Infra-red Cut Filter) layer 15, A spacer unit 16 and a lens unit 17 .

[0023] The image sensing unit 12 is a solid-state image sensing device, such as a charge-coupled sensing device (CCD) or a complementary metal-oxide-semiconductor device (CMOS). The image sensing unit may include a semiconductor substrate 121 and a photosensitive region 123 formed on one side of the semiconductor substrate 121 through a semiconductor process; the semiconductor substrate 121 may be a silicon substrate.

[0024] The spacer layer 13 is bonded to one side of the image sensing unit 12 where the photosensitive region 123 is formed, and is a ring structure, such as a square ring structure. The square ring structure may have a square outline and a circular through hole. The space...

no. 2 example

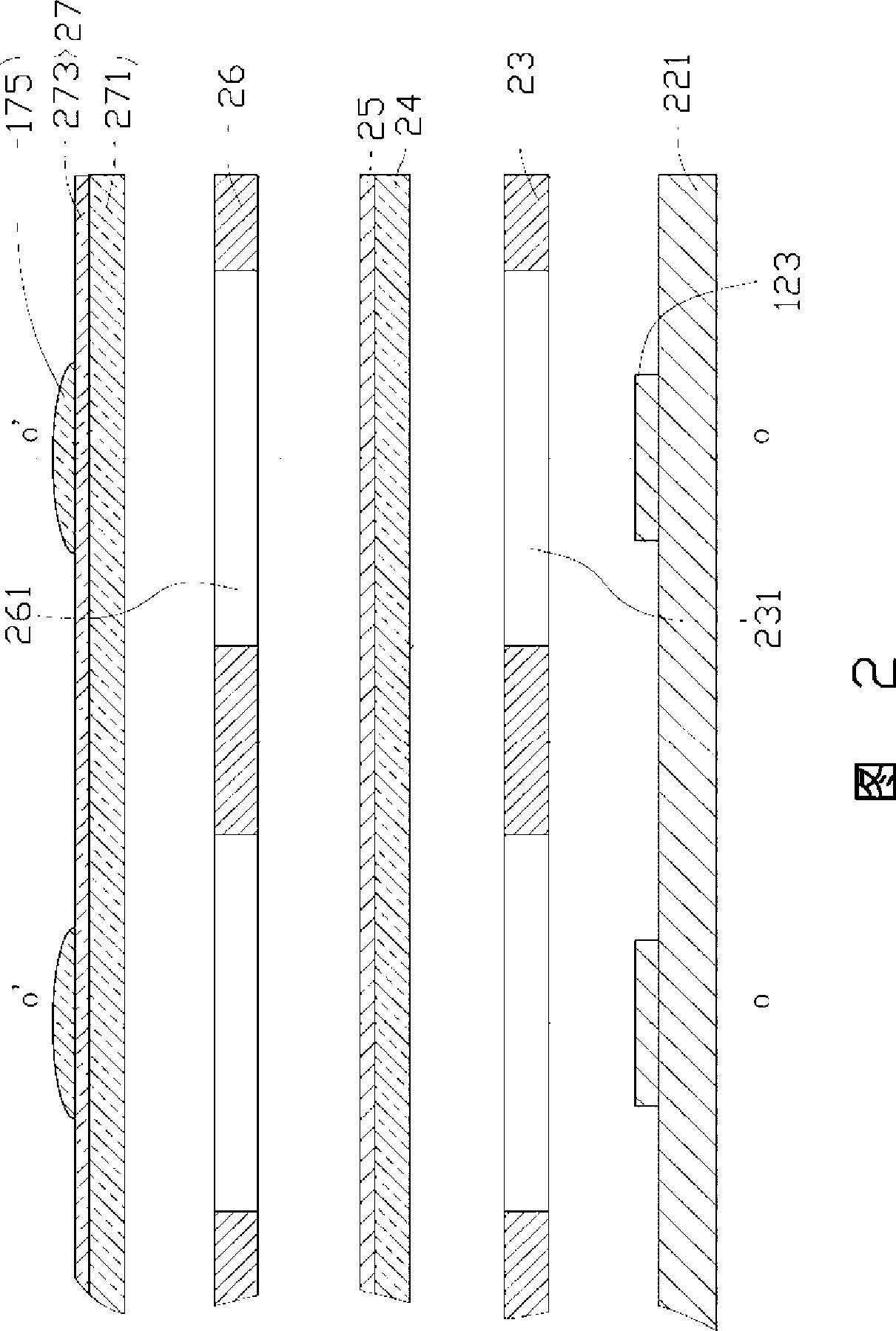

[0041] see Figure 4 The micro camera module 30 provided by the second embodiment of the present invention is basically the same as the micro camera module 10 provided by the first embodiment, including an image sensing unit 12, a spacer layer 13, a transparent cover plate 14, An infrared cut filter (Infra-red Cut Filter) layer 15, a spacer unit 16 and a lens unit 17; the image sensing unit 12 includes a semiconductor substrate 121 and a semiconductor substrate 121 formed on one side The photosensitive area 123. The difference is that the miniature camera module 30 further includes a lens unit 37 and another spacer unit 16 between the lens unit 37 and the lens unit 17 . The lens unit 37 includes a glass substrate 371 , a transparent nucleation layer 373 on the glass substrate 371 , and a lens 375 on the transparent nucleation layer 373 . The lens 375 of the lens unit 37 is arranged on the main optical axis OO′ of the lens 175 of the lens unit 17, and the lens unit 37 is bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com