Temperature control method in hot-rolled strip tailing-out process

A temperature control method and technology of hot-rolled strip steel, applied in the direction of temperature control, etc., can solve the problem of not being able to ensure the temperature of steel throwing well, and achieve the effect of improving temperature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

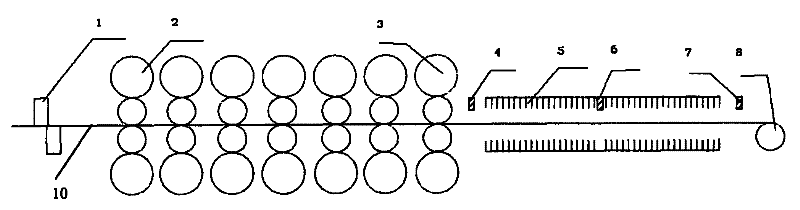

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] see Figure 6 Shown, a kind of temperature control method in the tail throwing process of hot-rolled strip steel of the present invention comprises the following steps:

[0039] A. According to the signal at the tail of the strip, confirm that the tail of the strip reaches the finish rolling flying shear and enters the tail cutting state.

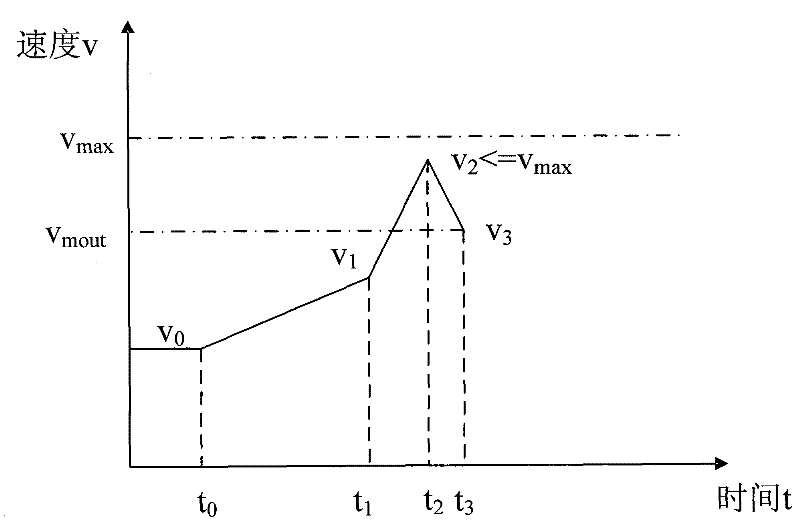

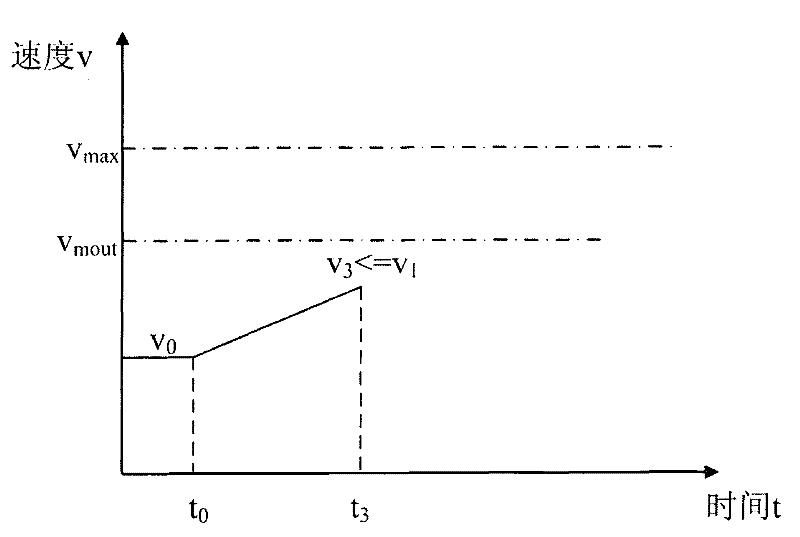

[0040] B. Through the dynamic control of the deceleration point of the highest speed, the steel throwing temperature at the tail of the strip is guaranteed to be constant.

[0041] C. According to the final rolling temperature and coiling temperature at the end of the strip when throwing steel, set the maximum cooling capacity when the strip passes through the laminar cooling area at the highest speed, and calculate the opening position of the first cooling valve.

[0042] D. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com