Method for smelting in reduction period of electric furnace steel making

An electric furnace steelmaking and electric furnace technology, applied in the direction of electric furnace, furnace, furnace type, etc., can solve the problems of upper and lower temperature, uneven composition, affecting normal production, poor reduction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

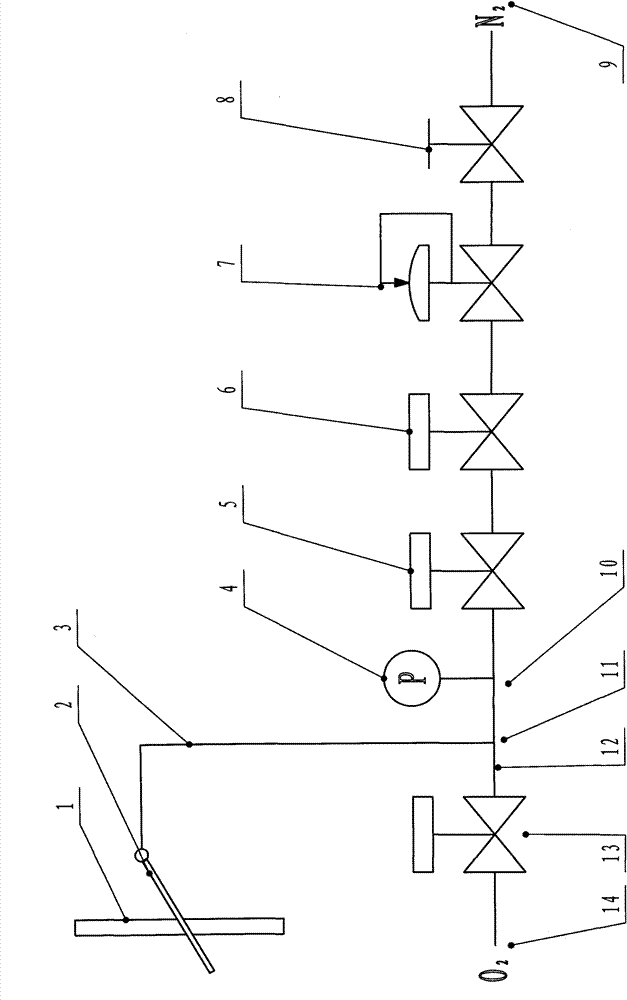

[0025] This embodiment takes 304 steel as an example to illustrate the method of smelting in the reduction period of electric furnace steelmaking. Use a thin tall ultra-high power electric furnace with a capacity of 90 tons, the power is 90WVA, and the model of the electric furnace is thin and tall. The electric furnace door used in this embodiment is connected to the pipes and valves for supplying oxygen and nitrogen, see figure 1 . The gas supply pipe 3 of the oxygen lance 2 of the electric furnace door 1 is connected with a three-way pipe 11, and the oxygen pipe 12 and the nitrogen pipe 10 are connected by the three-way pipe 11. The nitrogen pipe 12 is connected with a shut-off valve 13, and the nitrogen pipe 10 is connected with the pressure valve 4, the shut-off valve 5, the shut-off valve 6, the regulating valve 7 and the hand valve 8 in sequence. The oxygen pipe 13 is connected with the oxygen source, and the nitrogen pipe 10 is connected with the nitrogen source. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com