Metal roof ridge waterproofing system and mounting method thereof

An installation method and roof ridge technology, applied to roofs, roofs, roof coverings, etc., can solve problems such as rain and snow, and water leakage of pressed roof panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

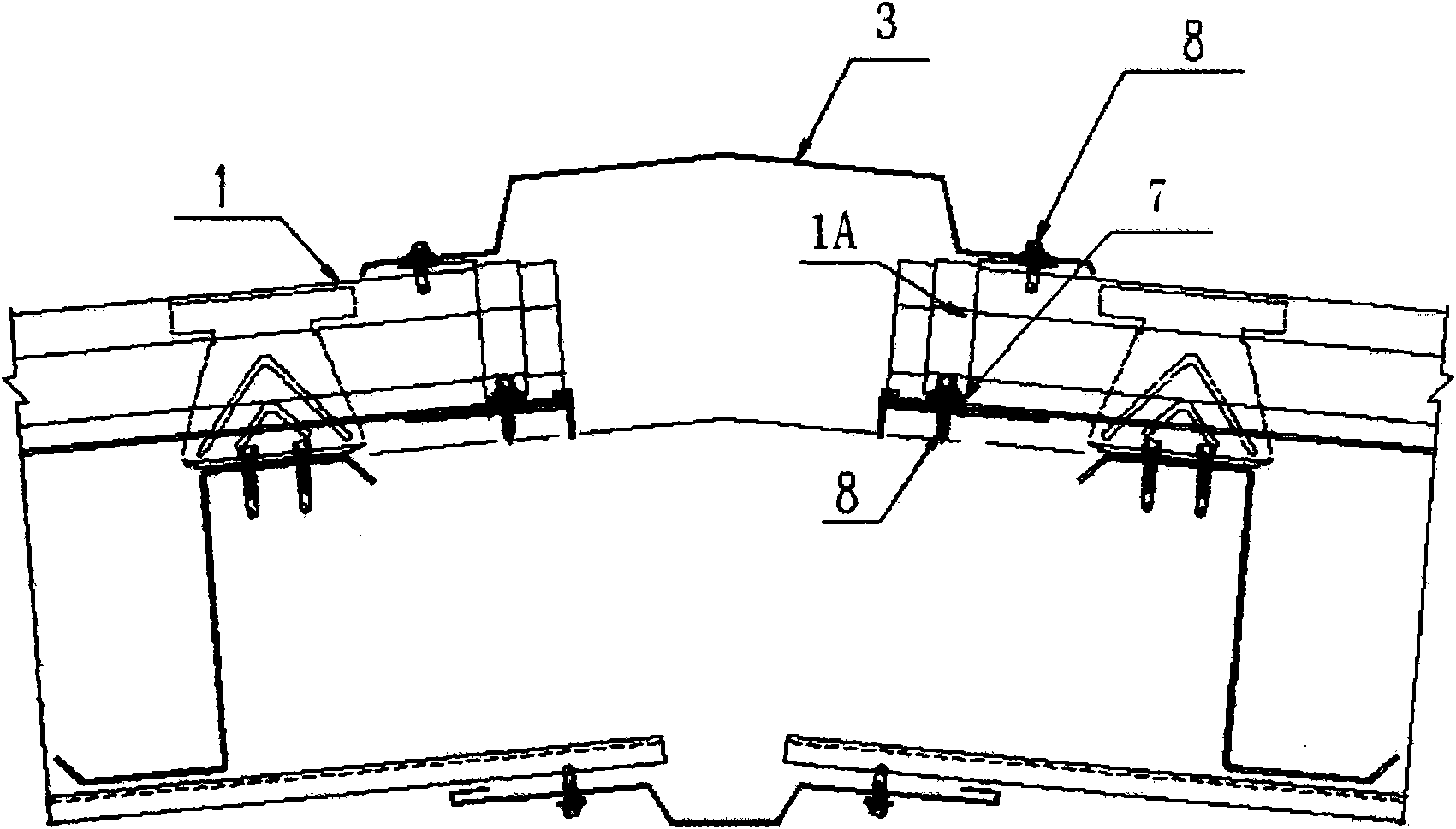

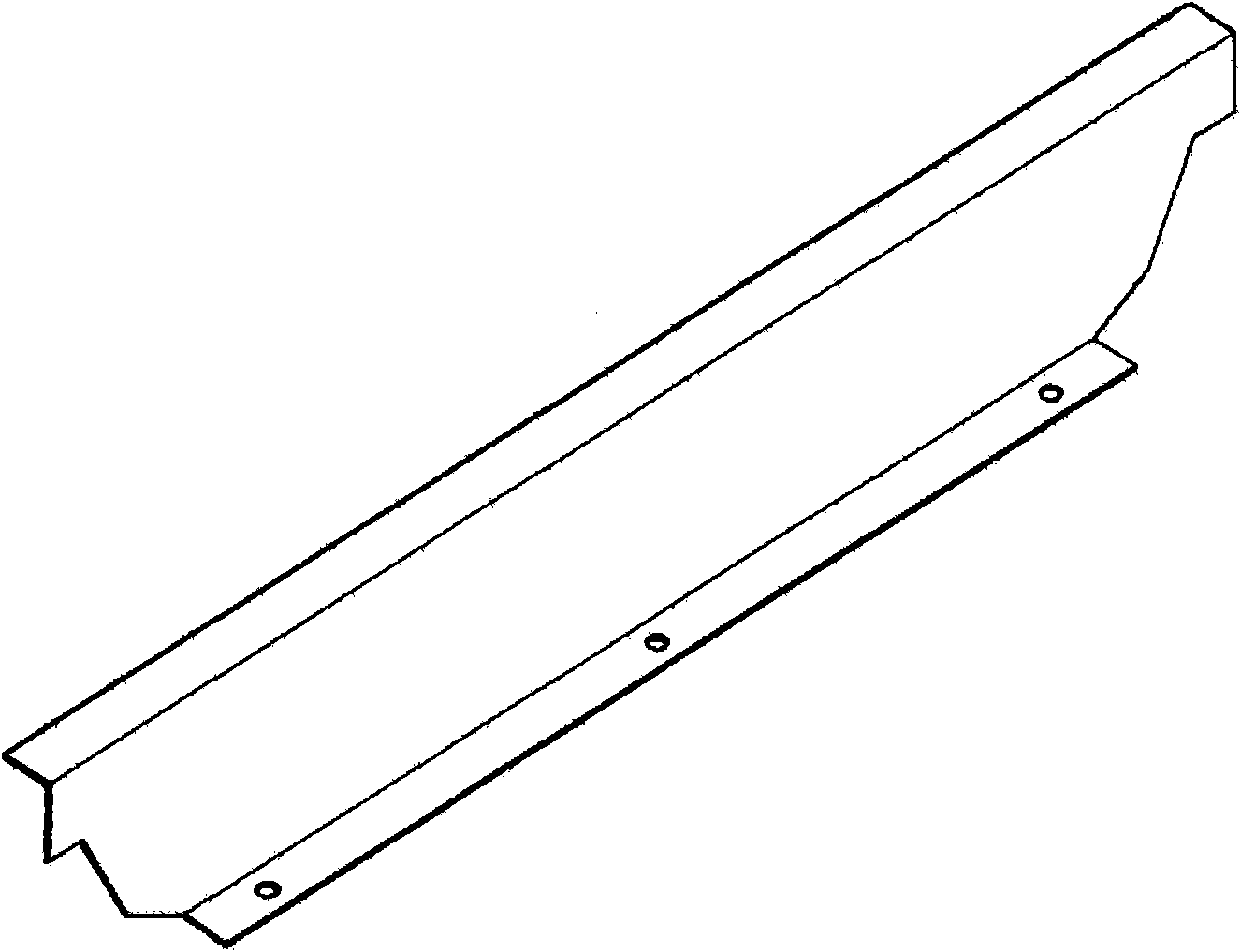

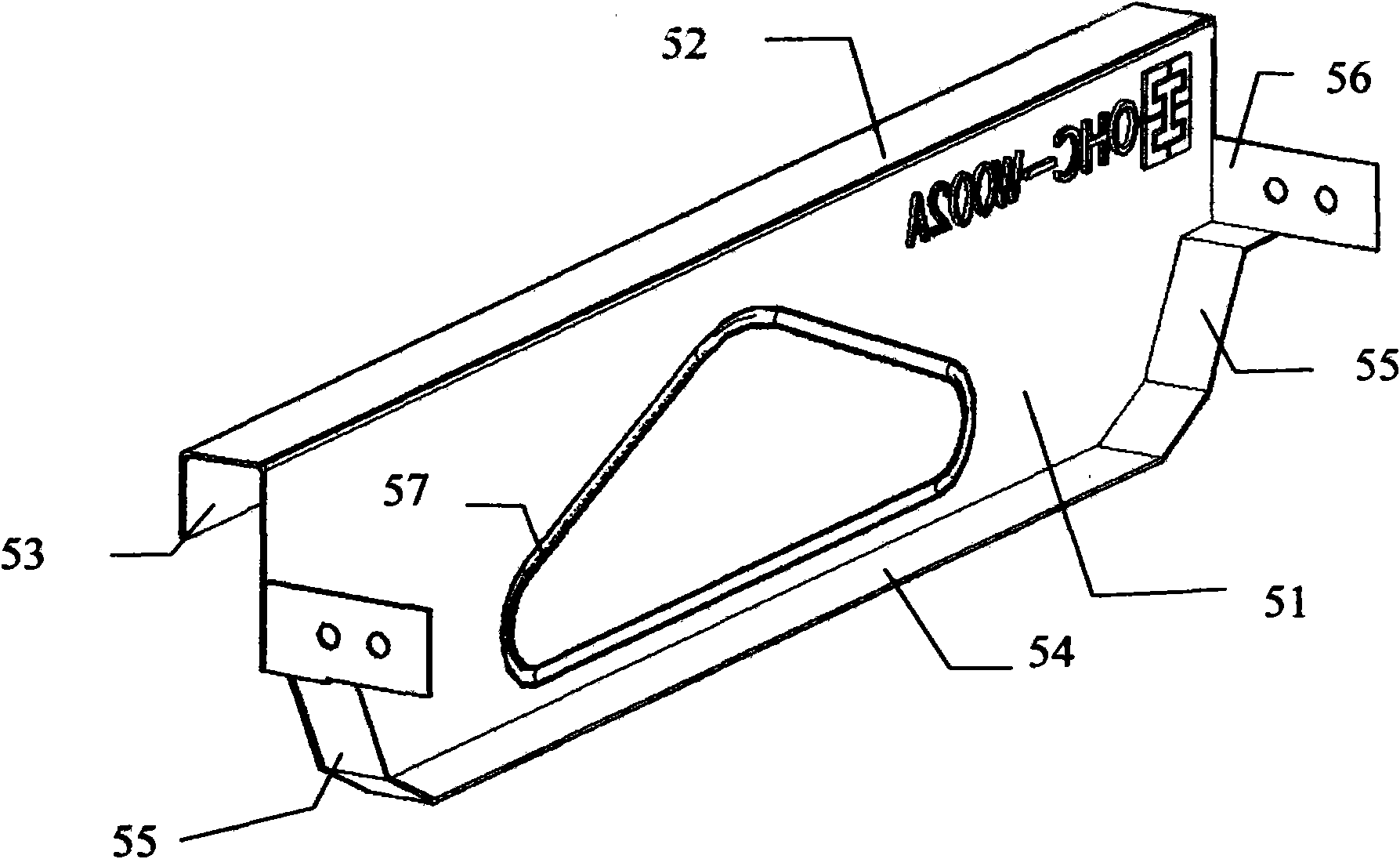

Embodiment 1

[0027] A metal ridge waterproof system, including a profiled roof panel 1, a roof flashing plate 3, and a roof ridge water retaining plate 5, the roof ridge water retaining plate is composed of a plug plate 51, a top end face 52, a folded edge 53, and a bottom end face 54 , two side end faces 55 and ear-shaped short sides 56. The width of the top end face 52 of the ridge water retaining plate is 2.5 cm, the height of the flange 53 is 3 cm, the width of the bottom end face and both sides end faces is 4 cm, and a triangular reinforcing rib 57 is provided on the plug plate 51 to increase the Surface rigidity, the shape on both sides of the plug plate is the same as the shape from the vertical side of the profiled roof panel to the trough, so that the ear-shaped short side 56, the end surfaces 55 on both sides and the bottom end surface 54 are respectively engaged with the profiled roof panel 1. The vertical edge and the vertical edge to the trough are tightly fitted, and it is co...

Embodiment 2

[0035] A metal ridge waterproof system, including a profiled roof panel 1, a roof flashing plate 3, and a roof ridge water retaining plate 5, the roof ridge water retaining plate is composed of a plug plate 51, a top end face 52, a folded edge 53, and a bottom end face 54 , two side end faces 55 and ear-shaped short sides 56, the width of the top end face 52 of the ridge water retaining plate is 2.5cm, the height of the folded edge 53 is 2.5cm, the width of the bottom end face and the two side end faces is 3.0cm, and the plug plate There are three ribs on the 51 to increase the rigidity of the board surface, such as Figure 9 As shown, the height h of the ear-shaped short side 56 is 2 / 3 of the height of the vertical lock seam of the profiled roof panel 1, and the width b is 5 cm. There are staple holes on the ear-shaped short side 56, and the roof ridge can be fixed by the staples. The ear-shaped short side of the water retaining plate is fixed on the vertical edge after the o...

Embodiment 3

[0041] A metal ridge waterproof system, including a profiled roof panel 1, a roof flashing plate 3, and a roof ridge water retaining plate 5, the roof ridge water retaining plate is composed of a plug plate 51, a top end face 52, a folded edge 53, and a bottom end face 54 , two side end faces 55 and ear-shaped short sides 56. The width of the top end surface 52 of the ridge water retaining plate is 2cm, the height of the folded edge 53 is 2.5cm, the width of the bottom end surface and the two side end surfaces is 2cm, and the shape on both sides of the plug plate is the same as the vertical edge of the profiled roof panel to the trough. The shape is the same so that the ear-shaped short side, the end faces on both sides and the bottom end face are closely attached to the profiled roof panel respectively. 3cm, the ear-shaped short side is punched with suture nail holes, and the ear-shaped short side of the ridge water retaining plate is fixed on the vertical edge after the occl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com