Liquid suspension and powder of cerium oxide particles, methods for making same and uses thereof in polishing

A cerium oxide, suspension technology, applied in the field of polishing, can solve the problem of complex development of suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

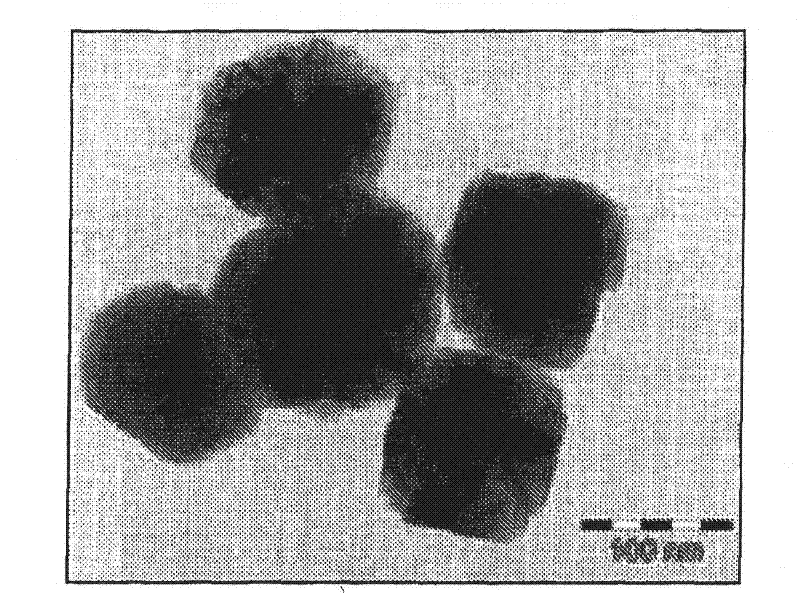

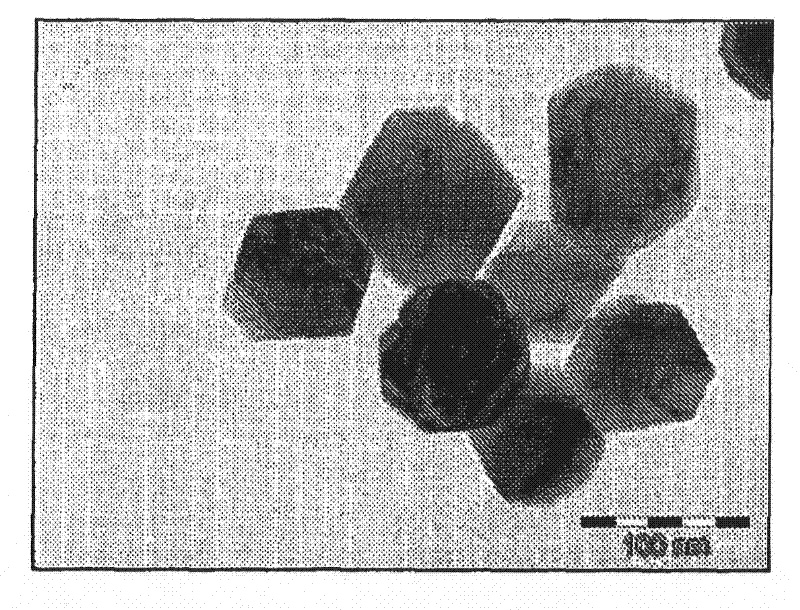

Image

Examples

preparation example Construction

[0049] The method for preparing the suspension of the present invention will now be described.

[0050] The suspensions of the invention can be prepared by a process comprising the following steps:

[0051] - (a) preparing a solution of a cerium III salt also comprising a colloidal dispersion of cerium IV;

[0052] - (b) bringing the solution into contact with a base under an inert atmosphere, whereby a precipitate is obtained;

[0053] - (c) subjecting the medium obtained in the previous step to a heat treatment under an inert atmosphere, at least one of the steps (a), (b) or (c) being carried out in the presence of nitrate ions;

[0054] - (d) acidifying and washing the medium thus obtained, successively but in any order, whereby a suspension is obtained.

[0055] The first step (a) of the above method thus consists in preparing the starting solution, which is a solution of the cerium III salt.

[0056] As cerium III salts it is possible more particularly to use nitrates,...

Embodiment 1

[0102] A starting solution was prepared by adding 830.6 g of a 2.88M solution of trivalent cerium nitrate (d=1.715) and 740 mg of a 0.70 M colloidal solution of cerium oxide with a particle size of 6 nm as determined by DQEL (d=1.115). will have a Ce of 1 / 3000 4+ / C 全部 The molar ratio of this solution was charged into a semi-closed container, and then degassed under vigorous stirring and nitrogen bubbling for 2 hours.

[0103] A dilute aqueous ammonia solution was prepared by adding 5041.0 g of deionized water and 423.9 g of 28% ammonia in water. The solution was charged to a semi-closed 6-liter jacketed reactor, which was then subjected to stirring and nitrogen sparging for 2 hours.

[0104] The previously prepared starting solution was then added to this dilute aqueous ammonia solution at ambient temperature over 30 min with stirring and a nitrogen purge.

[0105] Still under the nitrogen purge, the temperature of the reaction mixture was then raised to 85°C over 3 / 4 hour a...

Embodiment 2

[0114] The suspension obtained in Example 1 was diluted to CeO by adding deionized water 2 Calculated as 20% by weight. 100 g of this suspension were added to a solution of 100 g of polyacrylic acid (PAA) of molar mass Mw = 2000 g / mol under stirring, diluted so that the final PAA / CeO 2 The ratio is 1.2% by weight. The pH of the suspension thus obtained was brought back to 8 by adding 28% aqueous ammonia.

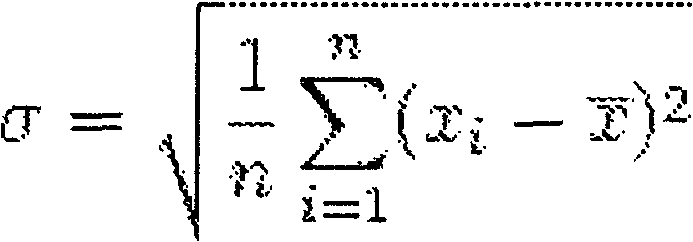

[0115] A value of 1.7 was adopted as CeO 2 Optical index in water, using Horiba LA910 laser particle size analyzer to measure the size of secondary particles. Median size d 50 112nm. Based on d of 93, 112 and 140nm respectively 10 、d 50 and d 90 The calculated dispersion index σ / m was 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap