Production method of full-docking oil tank heater assembling pipe

A production method and assembly pipe technology, which is applied in the field of full butt joint oil tank heater assembly pipes, can solve problems such as easy leakage, trachoma, and failure to detect flaws, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

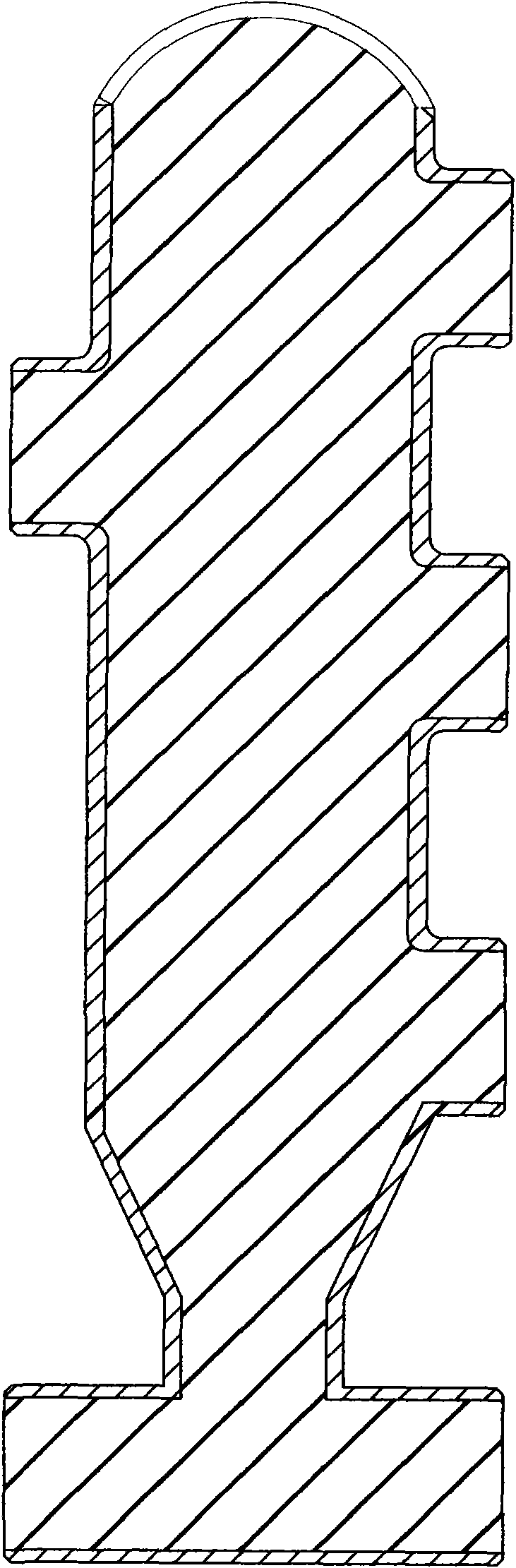

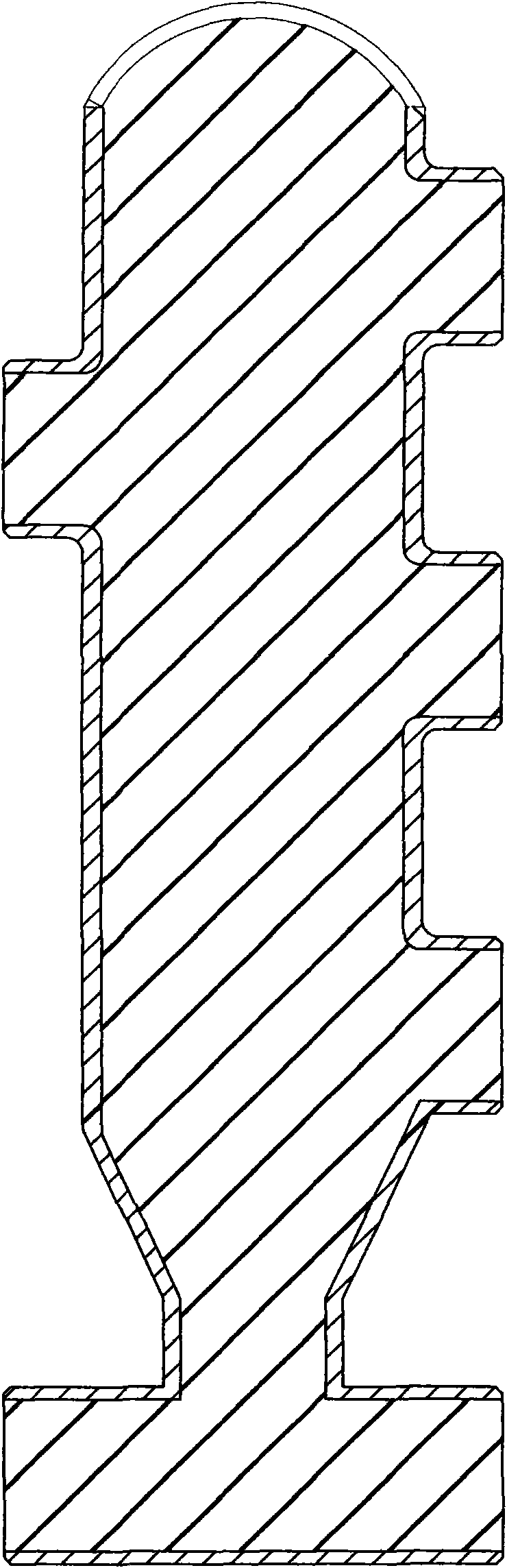

[0009] Make a pair of molds with the same shape and size as the half of the assembly pipe cut along the longitudinal direction and the same shape and size as the other half, then heat the steel plate used to make the assembly pipe, and hot press to form a pair of half-sided assembly pipes, and then This pair of half-faced manifolds is welded together to give a fully butted tank heater manifold.

[0010] It is also possible to make a pair of molds with the same shape and size as the half of the assembly pipe with a tee at the lower end and the same shape and size as the other half (refer to the accompanying drawing), and then heat and press the steel plate used to make the assembly pipe Forming to get a pair of half-face assembly pipes with a half-face tee at the lower end, and then welding the pair of half-face assembly pipes with a half-face tee at the lower end to obtain a full-butt oil tank heater assembly with a tee at the lower end Tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com