Device for guiding and clamping workpiece

A technology for processing workpieces and clamping devices, which is applied in metal processing and other directions, can solve problems such as compression marks of cylindrical parts, damage to cylindrical threads, etc., and achieve the effects of reducing production costs, avoiding time-consuming and labor-intensive production, and optimizing automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

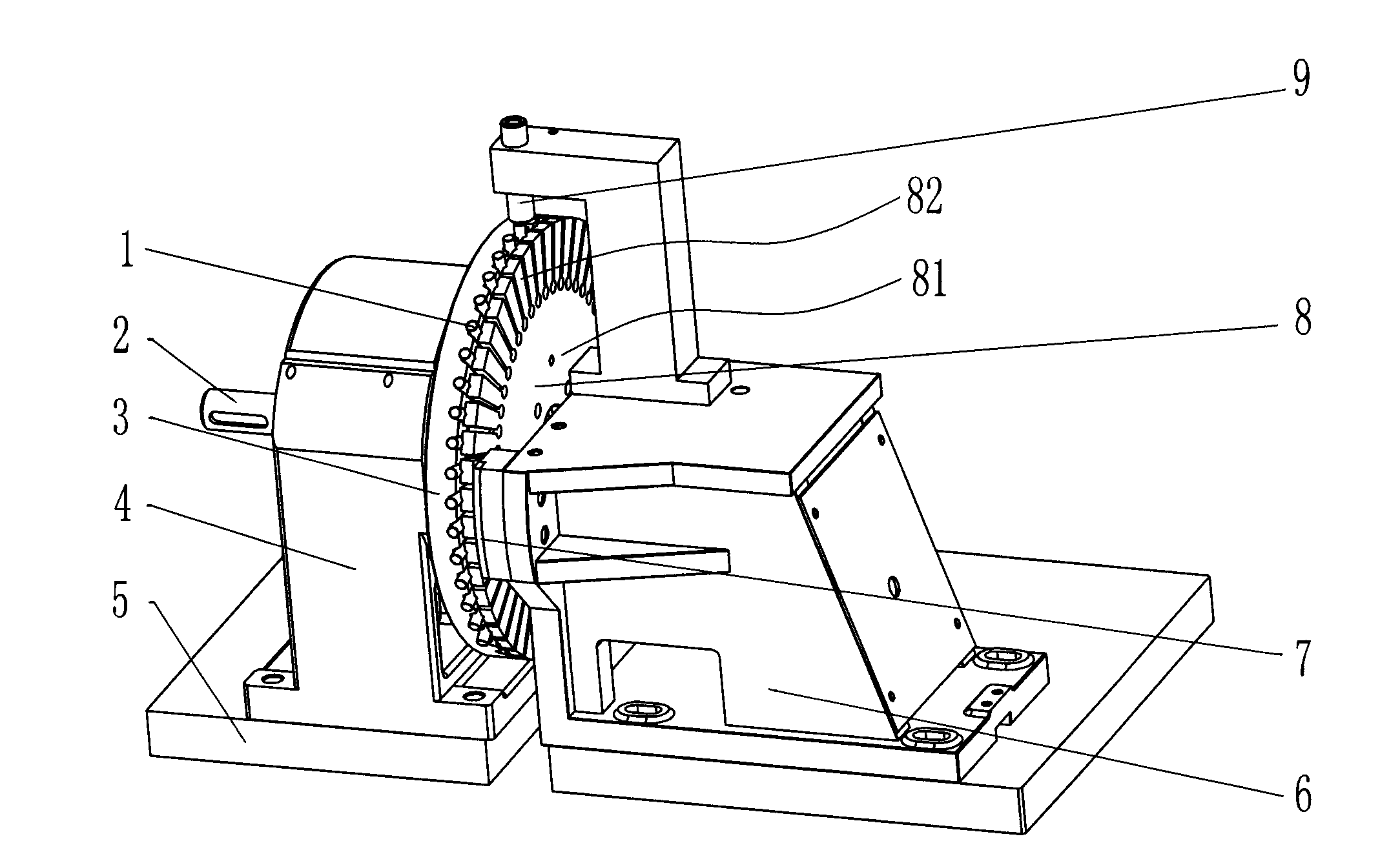

[0033] Such as Figure 1-3 Shown: a material guide and clamping device for processing workpieces, including: a clamping disc 3, a rotating shaft 2 that drives the clamping disc 3 to rotate, a shaft seat 4, and a pressing block matched with the clamping disc 3 7. The pressing block mounting seat 6 and the power source; characterized in that: a multi-elastic sheet pressing plate 8 is provided between the clamping disc 3 and the pressing block 7, and the multi-elastic sheet pressing The disc 8 rotates synchronously with the clamping disc 3, and is mainly composed of a base 81 and an elastic sheet 82 connected around the base.

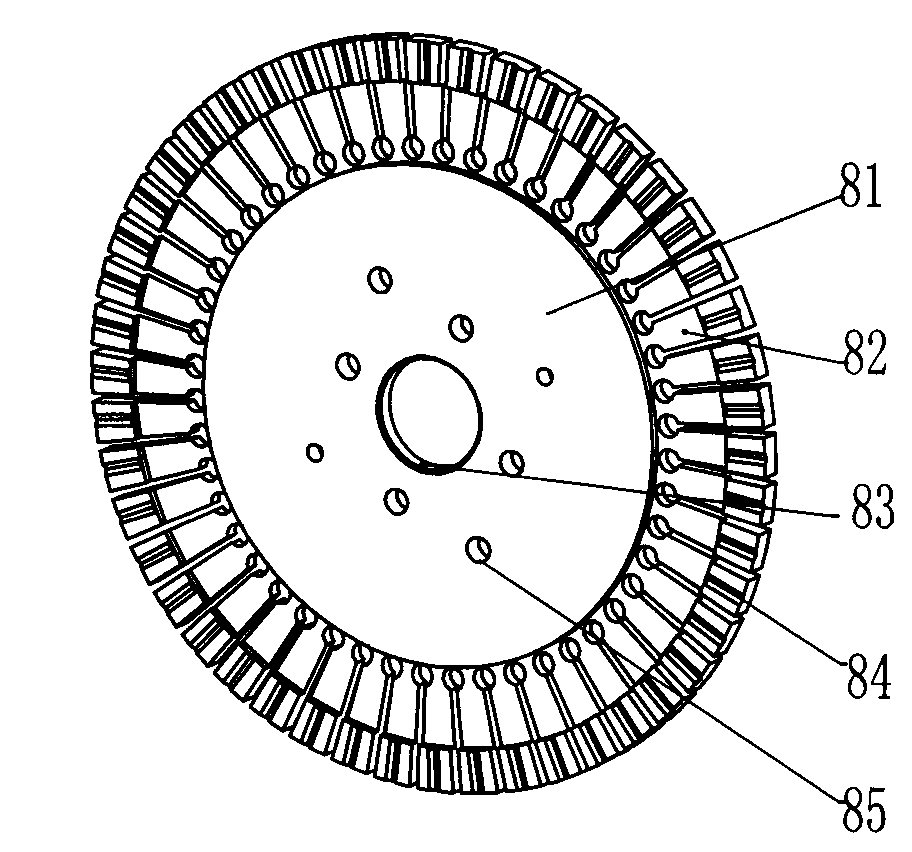

[0034] The multi-elastic sheet pressing plate 8 is coaxially installed with the clamping disc 3, and includes: a base 81, a plurality of elastic sheets, each corresponding to the position of the processing workpiece 1 on the clamping disc 3 82. Fix the multi-elastic sheet press plate 8 to the fixing screw hole 85 on the clamping disc 3. The multi-elastic sh...

Embodiment 2

[0039] The structure of Example 2 is basically the same as that of Example 1 (the figure is omitted). The multi-elastic sheet pressing plate is mainly composed of a base body and an elastic sheet connected around the base body ( Figure 4 , 5 ), the elastic sheet 82 is provided with a shaping groove 84 for clamping the processed workpiece, and the central hole 83 is not set in the center, and is fixed by a fixing screw hole 85.

Embodiment 3

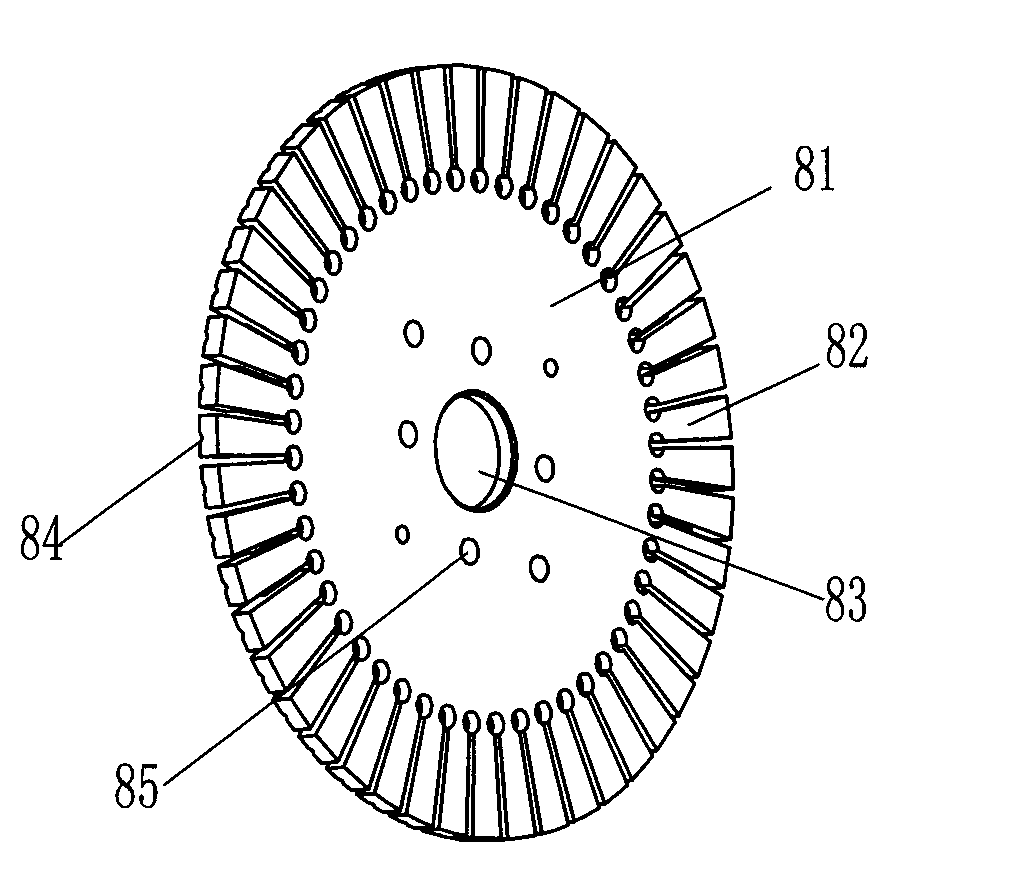

[0041] The structure of Example 3 is basically the same as that of Example 1 (the figure is omitted). The multi-elastic sheet pressing plate is mainly composed of a base body and an elastic sheet connected around the base body ( Image 6 , 7 ), the center is provided with a positioning center hole 83, and the elastic sheet 82 is not provided with a shaping groove 84 for clamping the workpiece. In this case, the elastic piece 82 cooperates with the "V" shaped groove on the clamping disc to clamp the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com