Knob structure for fixing side panel at outlet end of indoor machine of commercial air conditioner

A technology for the indoor unit and the outlet end of an air conditioner, which is applied in the field of fixed knob structures, can solve problems such as failure to ensure that the indoor unit is in good condition, maintenance tools are difficult to enter, and the body cannot be disassembled, so as to solve the problems of inconvenient maintenance or poor installation effect and save energy. The effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

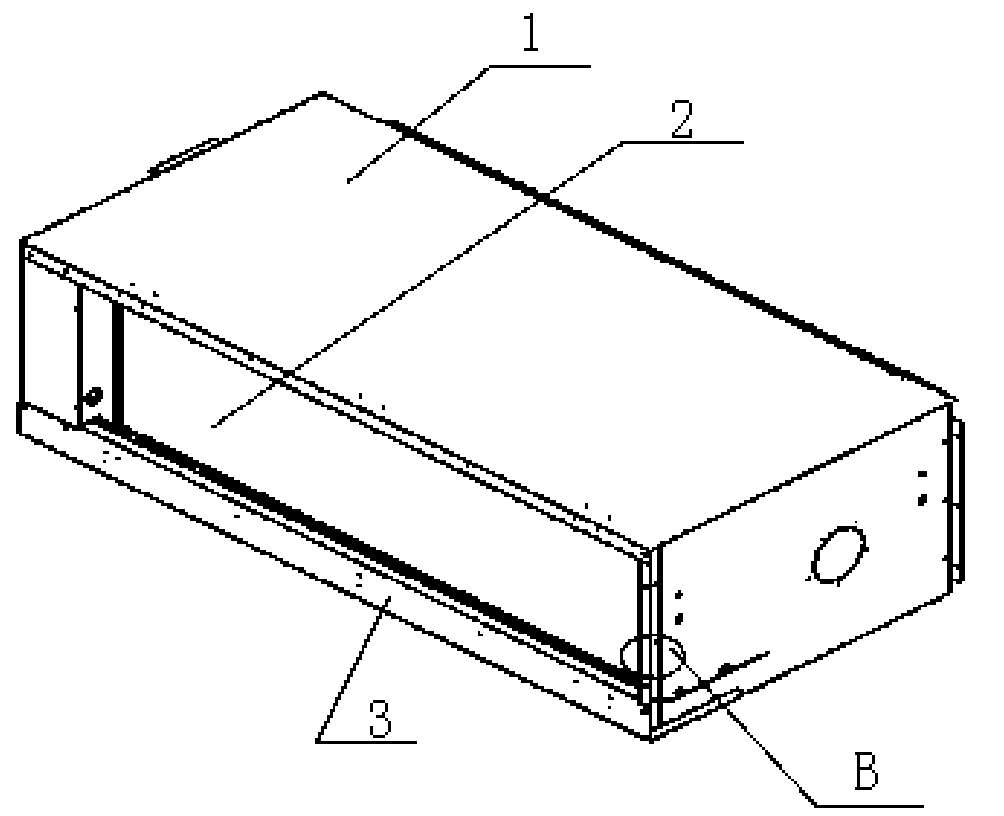

[0027] Next, the knob structure for fixing the outlet side panel of the commercial air conditioner indoor unit of the present invention will be described in detail with reference to the accompanying drawings and embodiments.

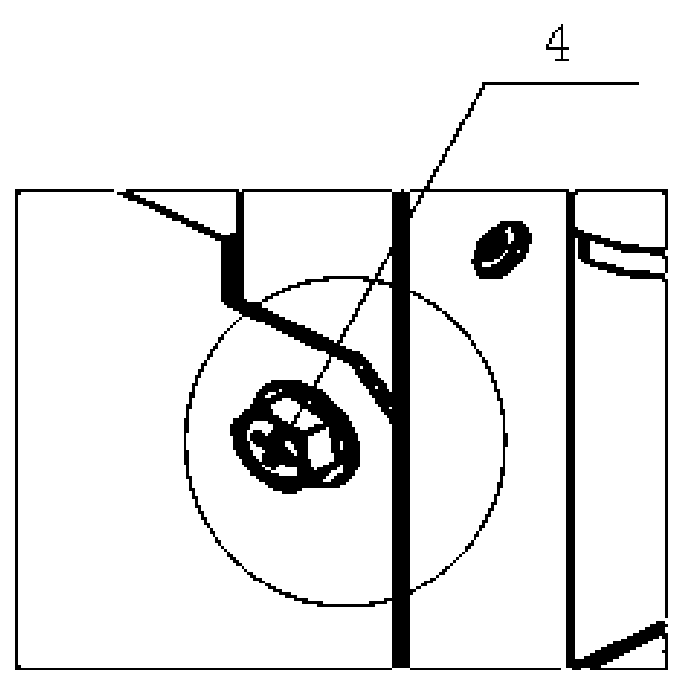

[0028] like Figure 4 , Figure 5 , Figure 7 As shown, the fixing knob structure of the outlet side panel of the commercial air conditioner indoor unit of the present invention includes a knob 5 and a knob formed on the front connecting piece 6 and the rear connecting piece 7 fixedly connected by the knob 5. Hole 8. That is, a corresponding knob insertion hole is formed at the junction of the side panel at the outlet end of the indoor unit of the commercial air conditioner and the housing of the indoor unit of the commercial air conditioner, and is fixedly connected through the knob 5 .

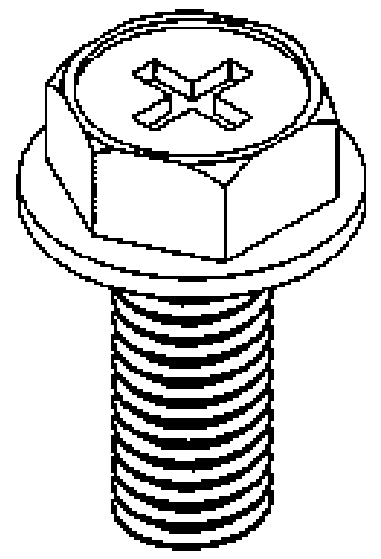

[0029] like Figure 6 As shown, the knob 5 includes: a handle 9 integrally formed from top to bottom for rotating force, a turntable 10 for snapping into the knob ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap