Hot-pressing sticking mechanism

A technology of sticking and thermal pressing head, which is applied in the field of flat panel display manufacturing equipment, can solve the problems of large instantaneous impact and inaccurate control of the pressing pressure of the thermal pressing head, and achieve the effects of avoiding impact, ensuring safety and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

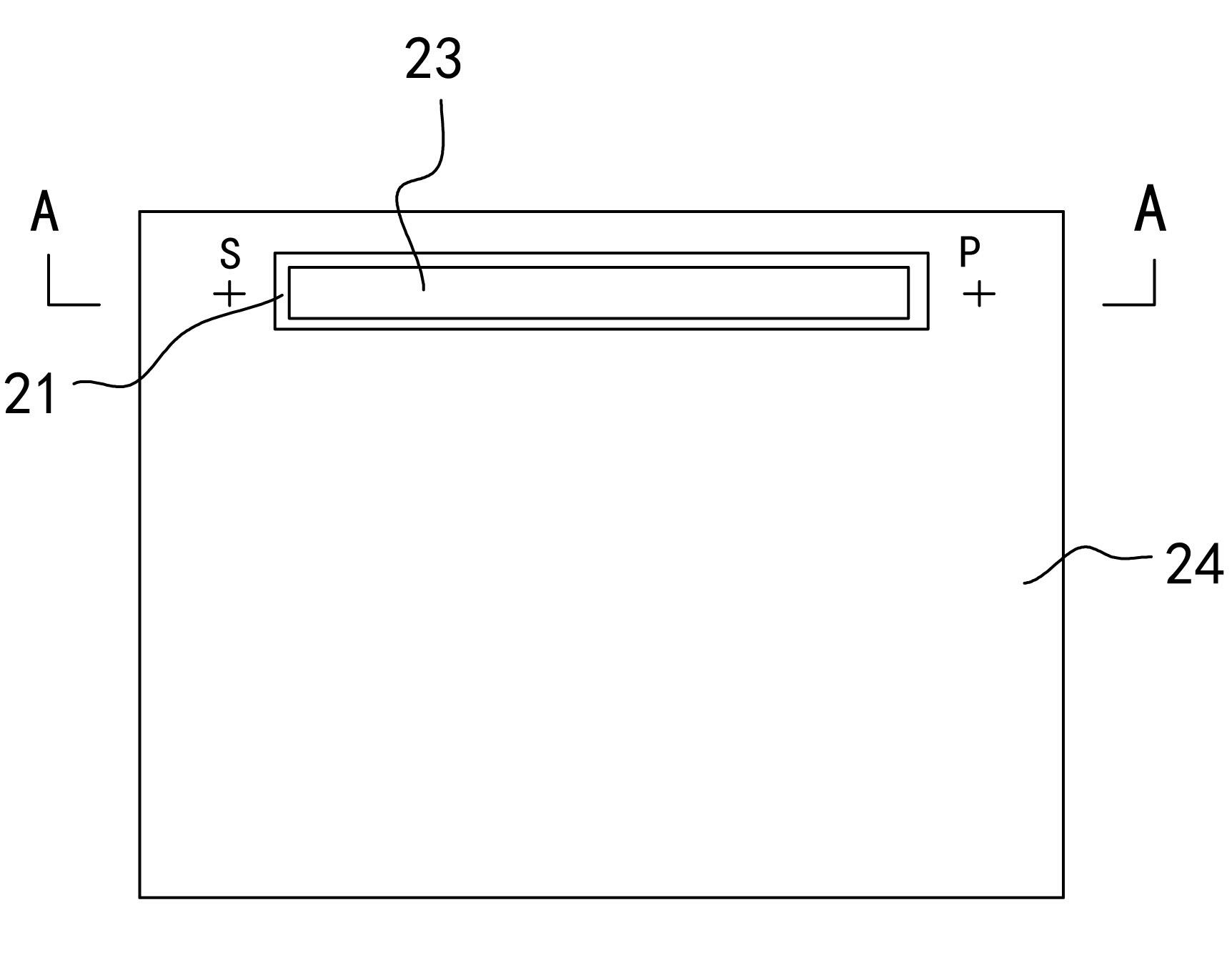

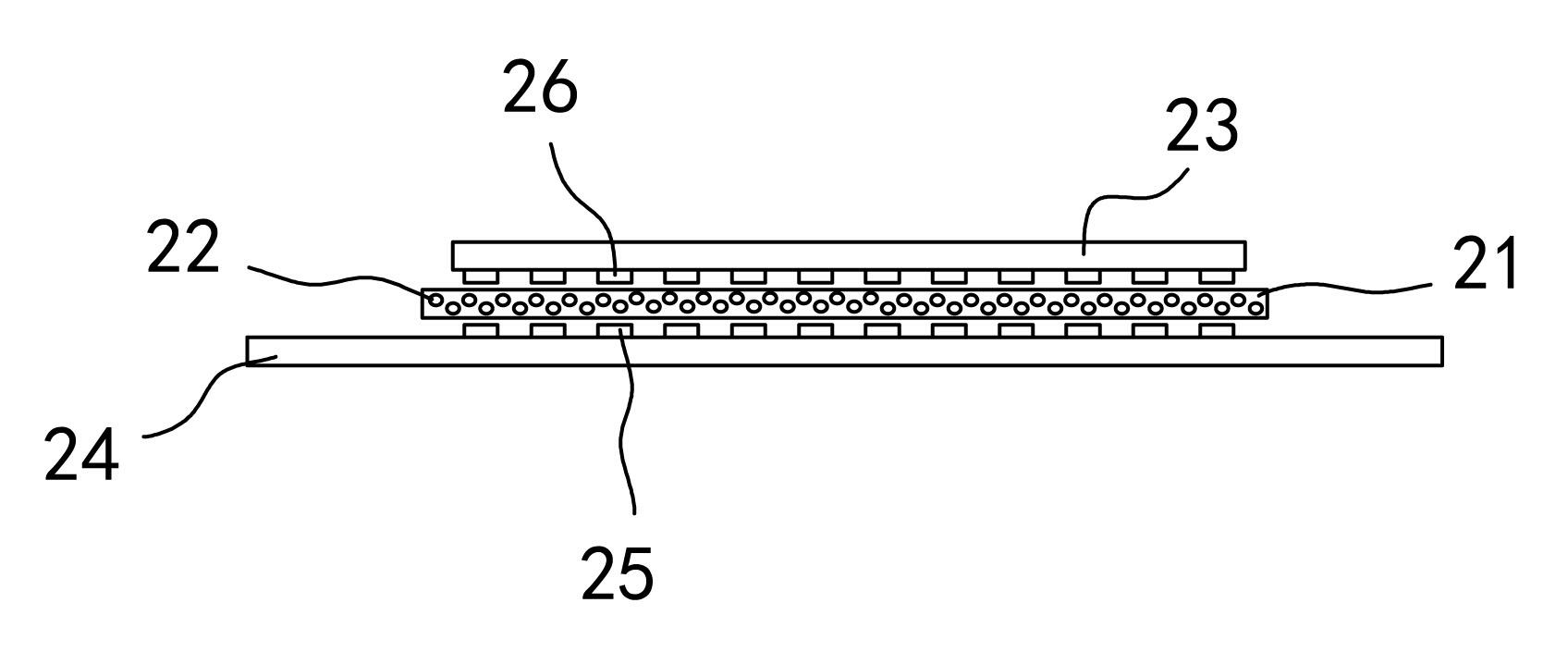

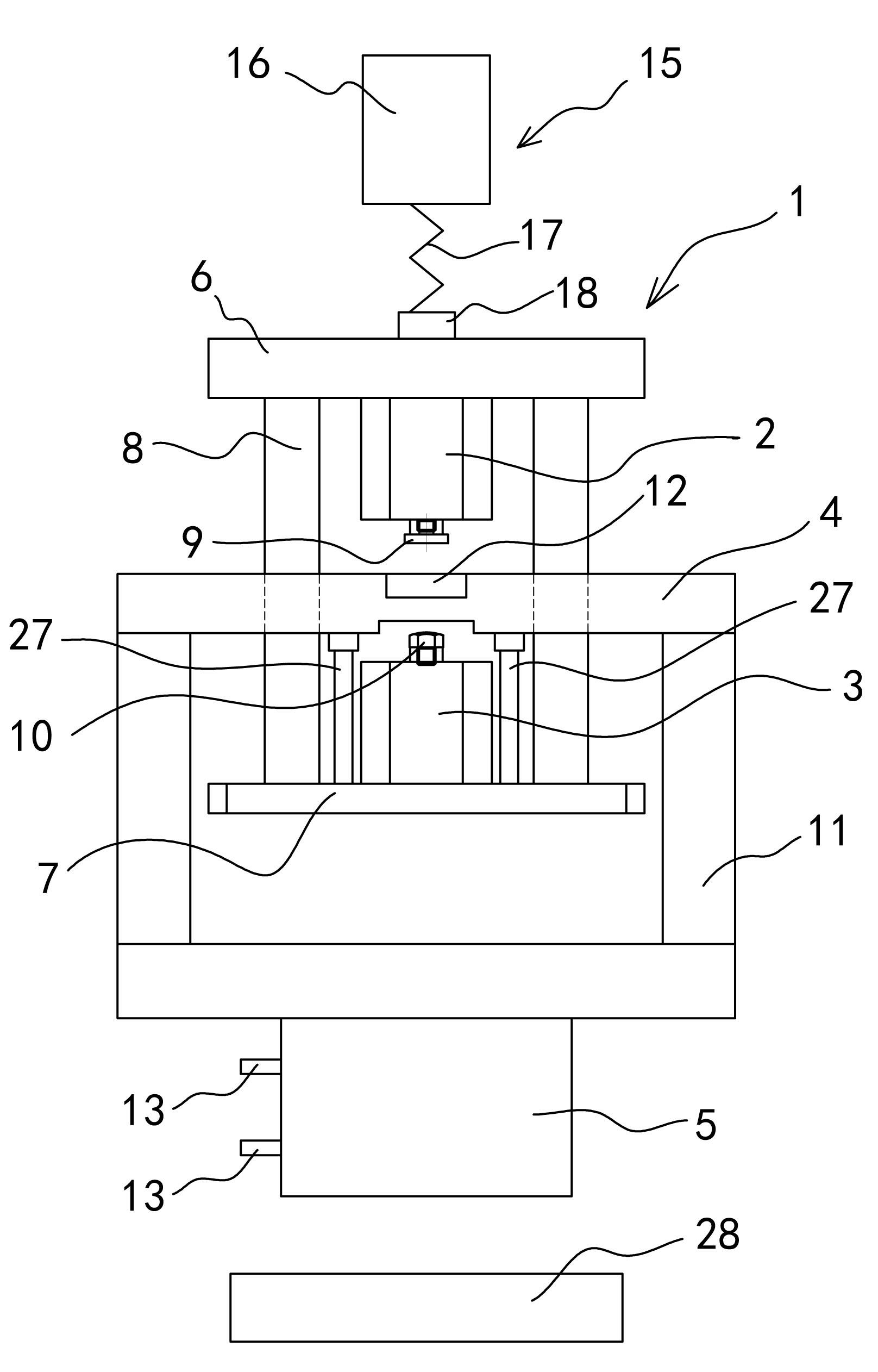

[0023] Example: see attached image 3 , 4 Shown:

[0024] A hot pressing application mechanism, comprising a supporting frame 1, an upper pressing cylinder 2, a lower supporting cylinder 3, a middle balance plate 4, a hot pressing head 5 and a table top 28, the supporting frame 1 is mainly composed of an upper supporting beam 6, a lower supporting beam The supporting beam 7 and two vertical columns 8 connected between the upper supporting beam 6 and the lower supporting beam 7 are formed; 1 is slidingly connected in the up and down direction; the upper pressing cylinder 2 is set upward and downward by the upper support beam 6, and its piston rod action end 9 is aligned with the top surface of the middle balance plate 4, and the lower supporting cylinder 3 is supported by the lower The beam 7 is arranged upwards, and its piston rod action end 10 is aligned with the bottom surface of the middle balance plate 4; the thermal pressure head 5 is arranged below the support frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com