Process for holding down transformer body

A transformer and body technology, applied in the field of transformer body compression technology, can solve the problems of increasing the surface moisture absorption of insulating parts, prolonging the exposure time of the body to the atmosphere, and the deformation of the disc spring cannot be observed, so as to ensure product quality, The effect of shortening the time of pressing the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

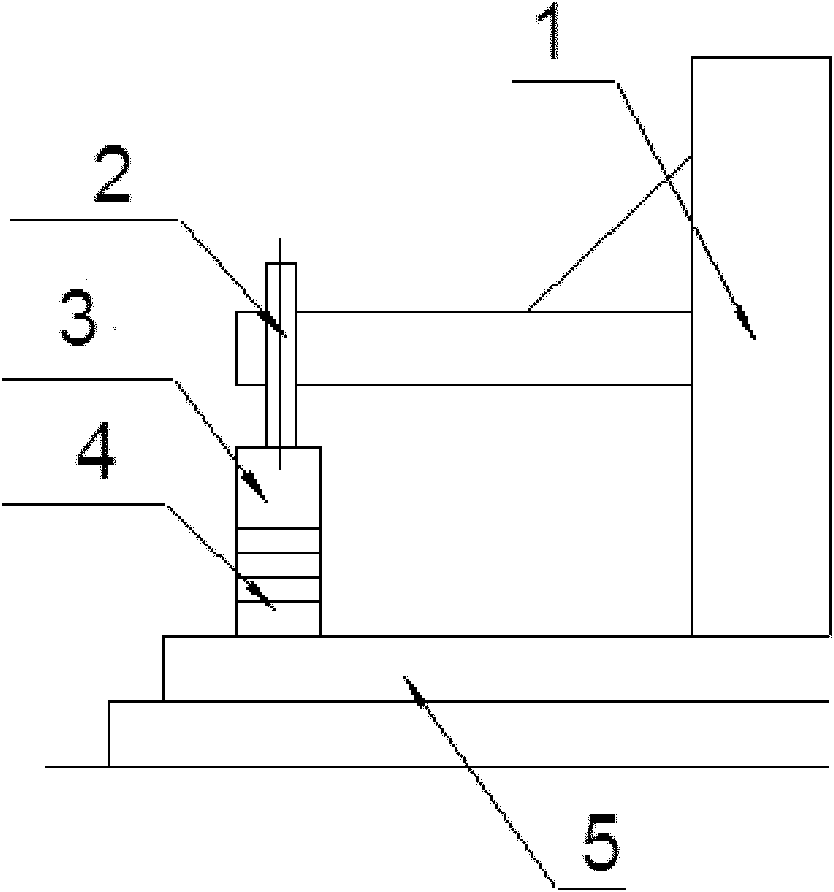

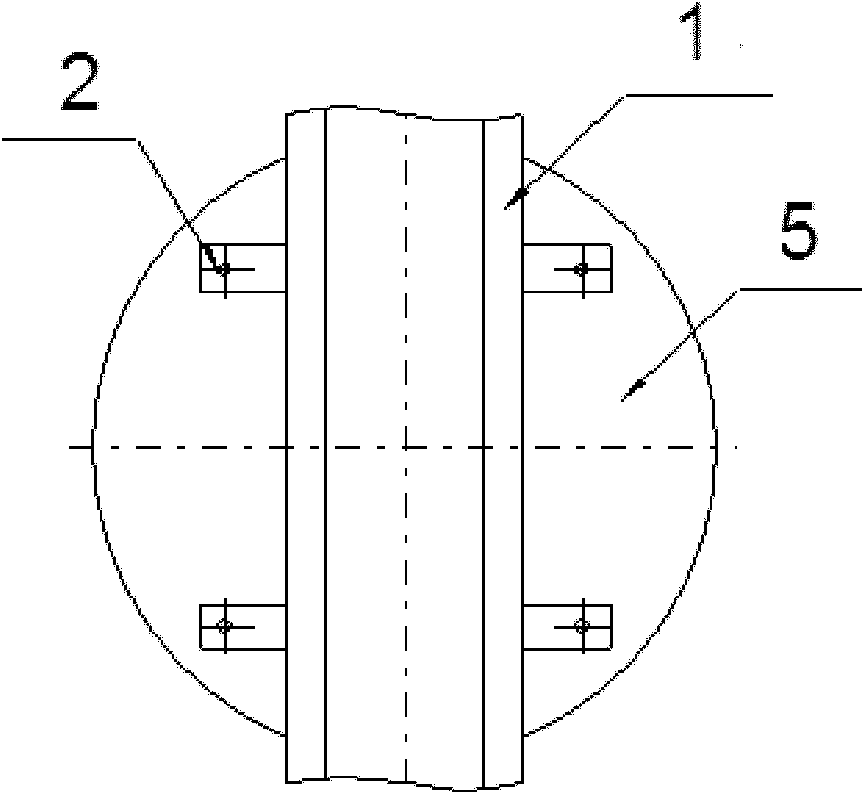

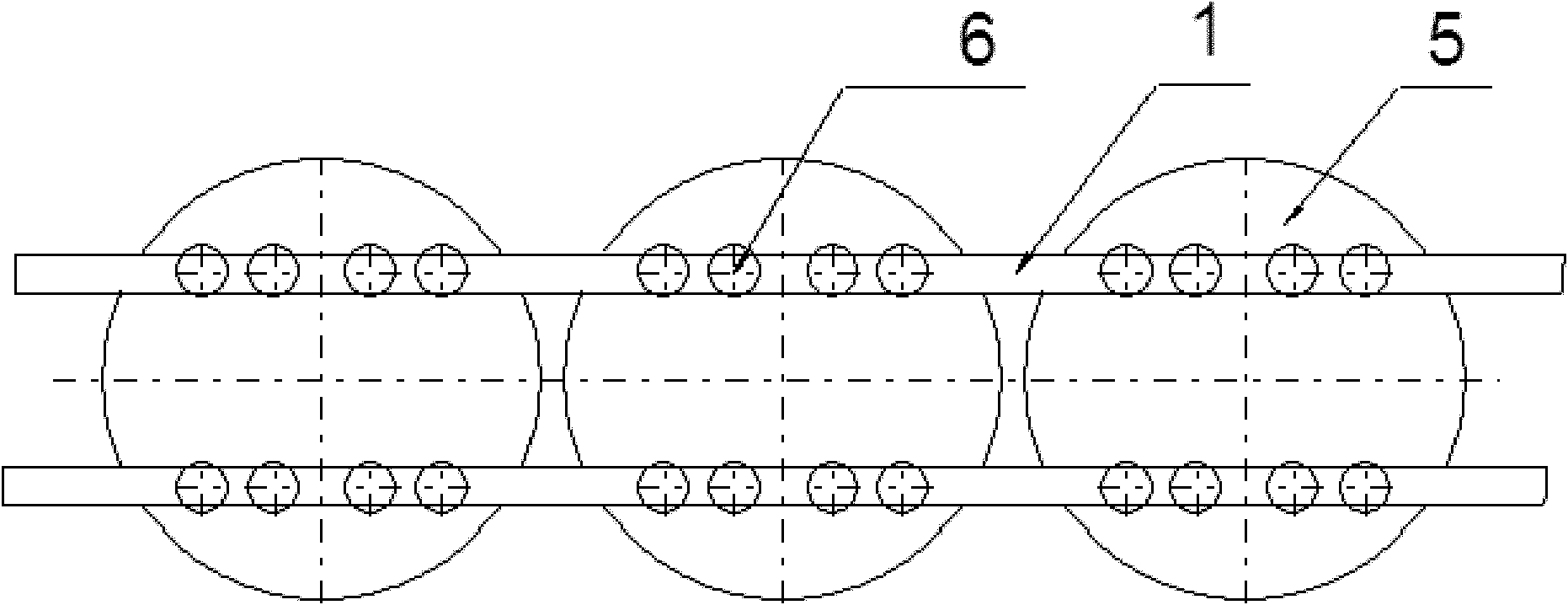

[0018] Such as image 3 , Figure 4 As shown, a transformer body compression process includes the following steps:

[0019] (1) Use the hydraulic cylinder 6 to replace the compression cylinder liner 3 of the traditional process. The clips 1 span the three-phase body 5 and are parallel to each other (one on the high-pressure side and one on the low-pressure side). There are 4 hydraulic cylinders between the two sides; the hydraulic cylinders set on the clamps on both sides are symmetrical to each other, and there are 8 cylinders in each phase;

[0020] (2) Each hydraulic cylinder is connected to the hydraulic station through a pipeline with a quick connector, and the oil pressure of the hydraulic station is used to exert pressure on the cylinder. The pressure is observed by the pressure gauge of the hydraulic station, and the pressure value is calculated. The pressure of the oil cylinder is uniformly controlled, so that the three-phase body is under the same pressure at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com