Contactor

A contactor, moving contact technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., to achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be specifically described below with reference to the drawings.

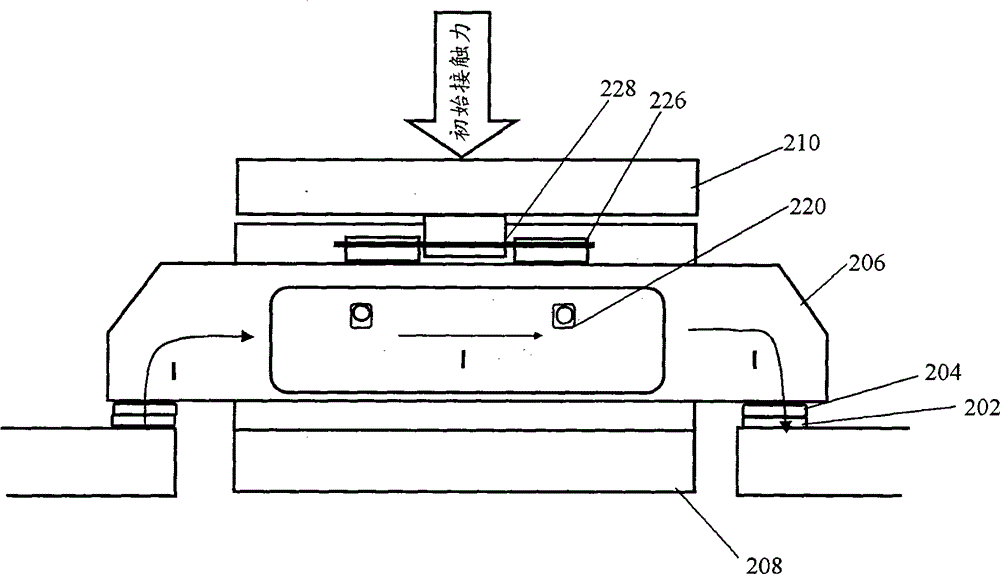

[0032] figure 1 It is a front view of an embodiment of the contactor of the present invention. The contactor includes a housing 200 (in figure 1 not shown in), the fixed contact 202, the movable contact 204, the movable contact finger 206 electrically connected with the movable contact, the U-shaped magnetic circuit 208 surrounding the movable contact finger, and the U-shaped magnetic circuit opening The plate-shaped magnetic circuit 210 is opposite and separated by an air gap. The movable contact finger 206 extends across the U-shaped magnetic circuit along a plane of symmetry of the U-shaped magnetic circuit. The movable contact 204 is disposed below both ends of the movable contact finger 206 . The fixed contact 202 is opposite to the movable contact 204 .

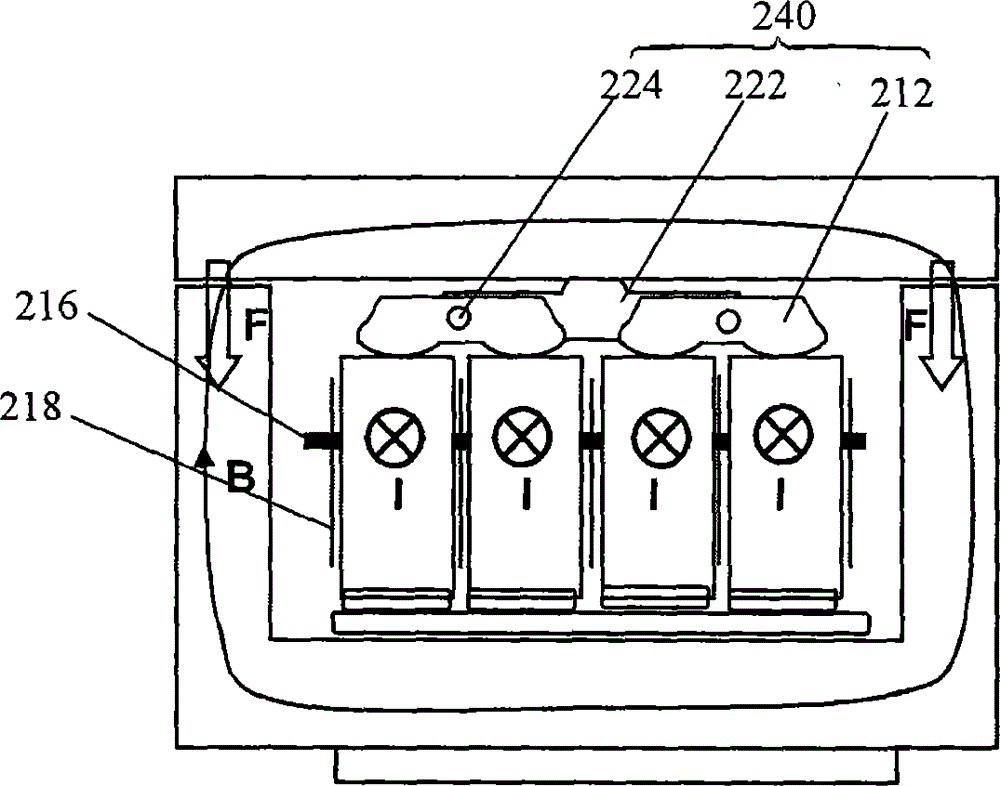

[0033] figure 2 is a side view of the contactor. from figure 2 It can be seen that there are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com