Method and device for controlling a steam power plant

A power station, steam technology, applied in the direction of steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as inadmissible load flow and frequency problems, power drop at generator terminals, inability to distinguish between power reduction and short circuit interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

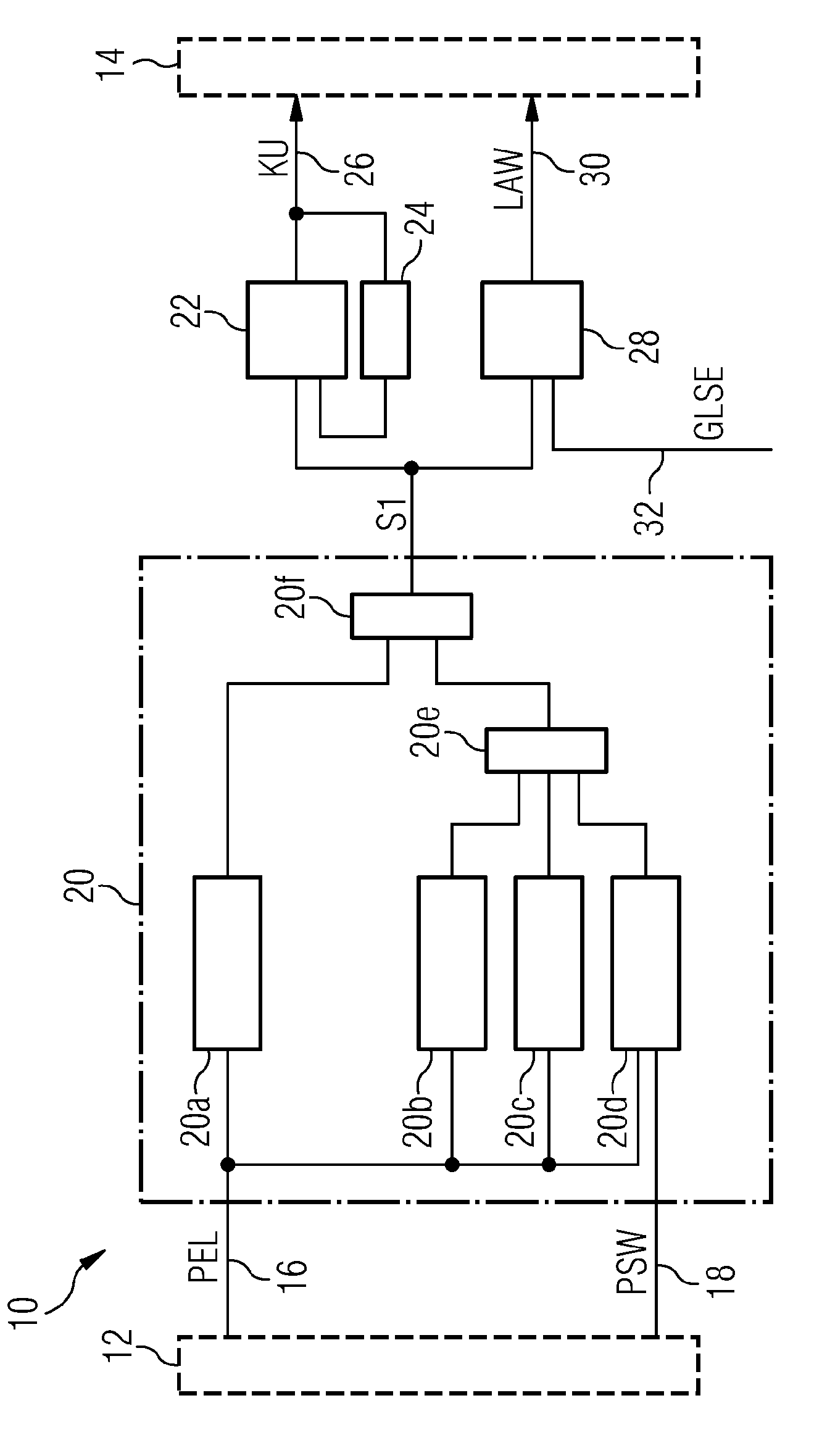

[0025] exist figure 1 A circuit arrangement or a device 10 for controlling a steam power plant with a generator 12 and a turbine 14 , which is not further shown, is indicated in the center. As basic elements, the device 10 comprises a PEL signal line 16 and a PSW signal line 18 , which lead from the generator 12 to a device 20 for providing a first signal. The device 20 is designed as a control or control device, a total of six switching elements 20 a , 20 b , 20 c , 20 d , 20 e and 20 f being formed. In this case, the actual power (PEL) of the generator 12 is transmitted via the PEL signal line 16 to a circuit element 20 a which checks whether the actual power drops abruptly by a predetermined value GPLSP. In this case, in particular a reduction in the jump pattern of greater than 70% is currently being checked. In order to check such power jumps, the power signal PEL is first filtered through the DT1 link.

[0026] In the switching element 20b, it is deduced from the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com