Washer, screw or nut with increased coefficient of friction

一种螺栓、垫圈的技术,应用在垫圈,螺栓或螺母领域,能够解决解决办法昂贵、复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

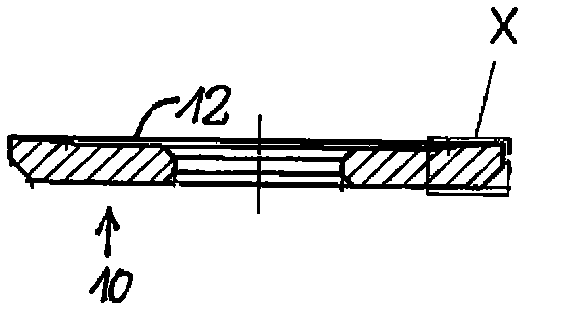

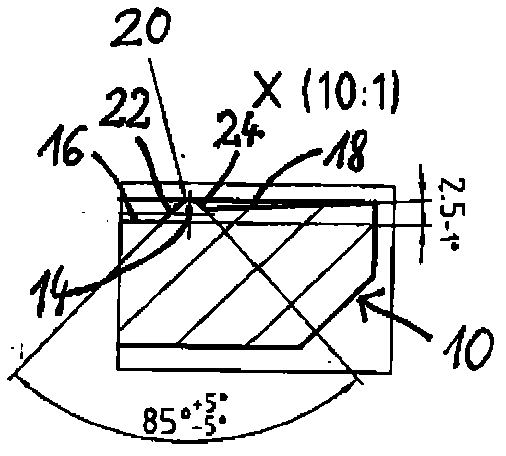

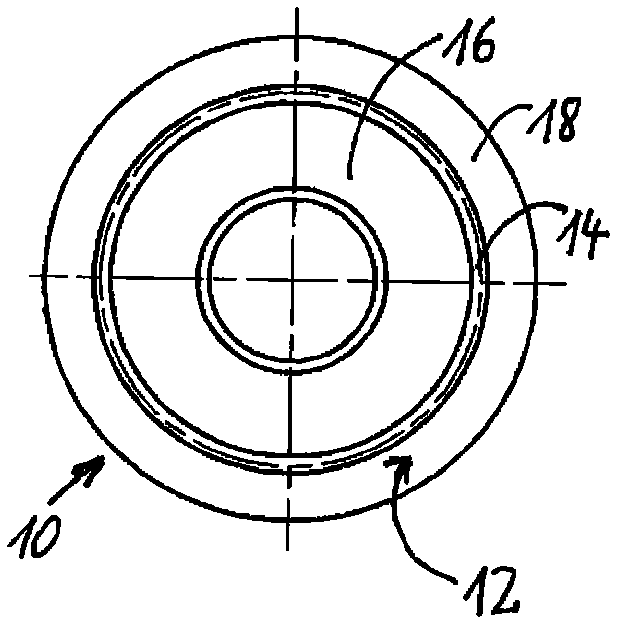

[0018] figure 1 is a cross-sectional view of a washer 10 according to the invention, the section being taken along the axis of rotation. The gasket 10 includes an end face 12 facing the workpiece when the gasket 10 is installed. as passed figure 2 and image 3 Seen more clearly, a concentric annular web 14 is connected to this end face 12 .

[0019] as available from figure 2 As can be seen particularly clearly, the region 16 of the end face 12 within the annular rim 14 is arranged to be recessed relative to the workpiece, preferably 0.2 to 0.4 mm deeper than the rim.

[0020] if possible through figure 2 It can be seen more clearly from the detailed view that the area 18 of the end face 12 outside the annular rim 14 is inclined by 1.5 relative to the plane of the workpiece in such a way that the distance between the workpiece and the surface of the gasket 10 increases from the outside towards the web beam 14 to 2.5°.

[0021] as available from figure 2 It is clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com