Improved spiral wing water meter

An improved wing water meter technology, which is applied in the direction of volume/mass flow generated by detecting the dynamic effect of fluid flow and mechanical effect, can solve the problems of inaccurate measurement, unbalanced force on blades, and reduced accuracy, etc., to achieve The effect of improving measurement accuracy, improving measurement accuracy and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

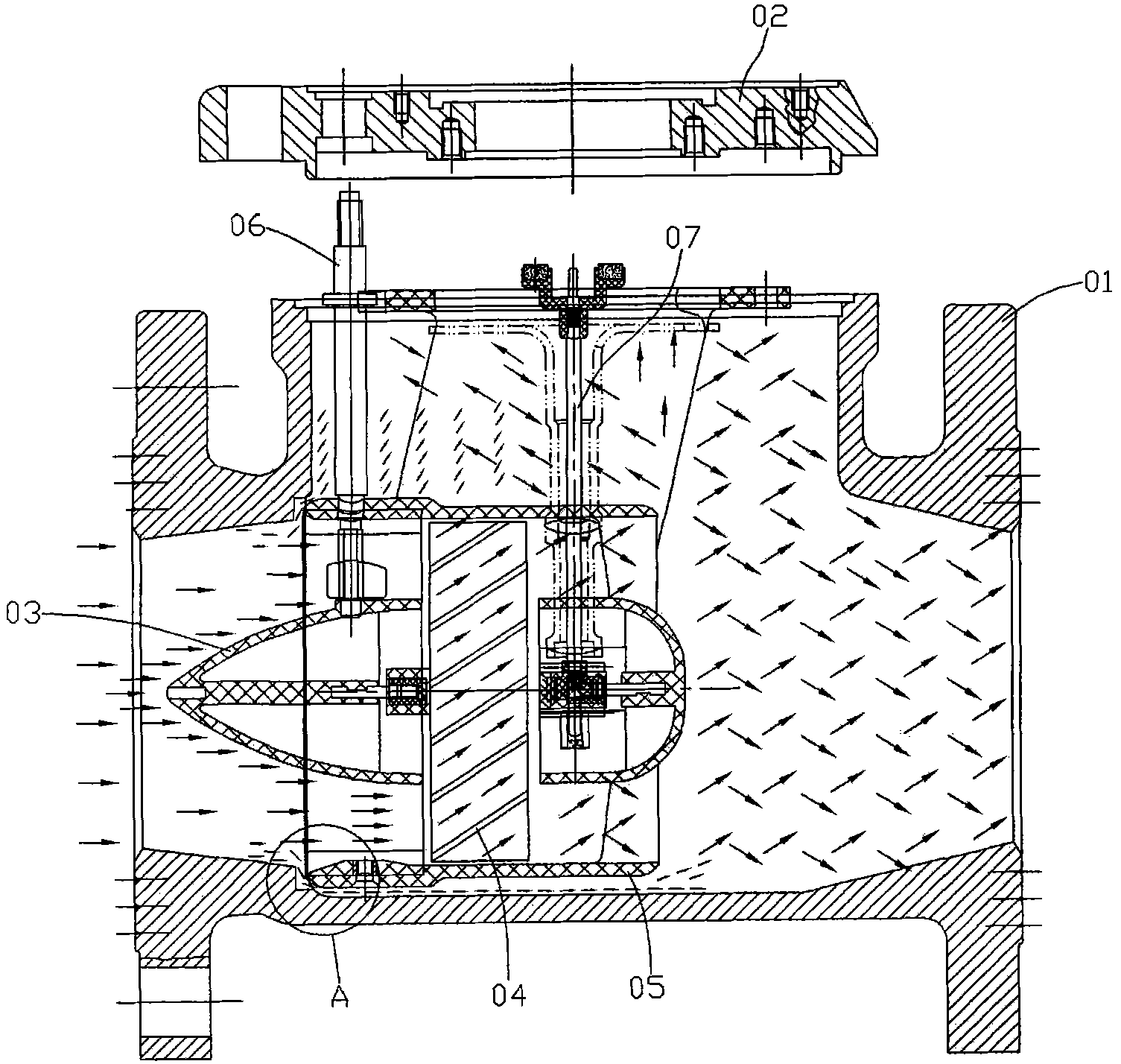

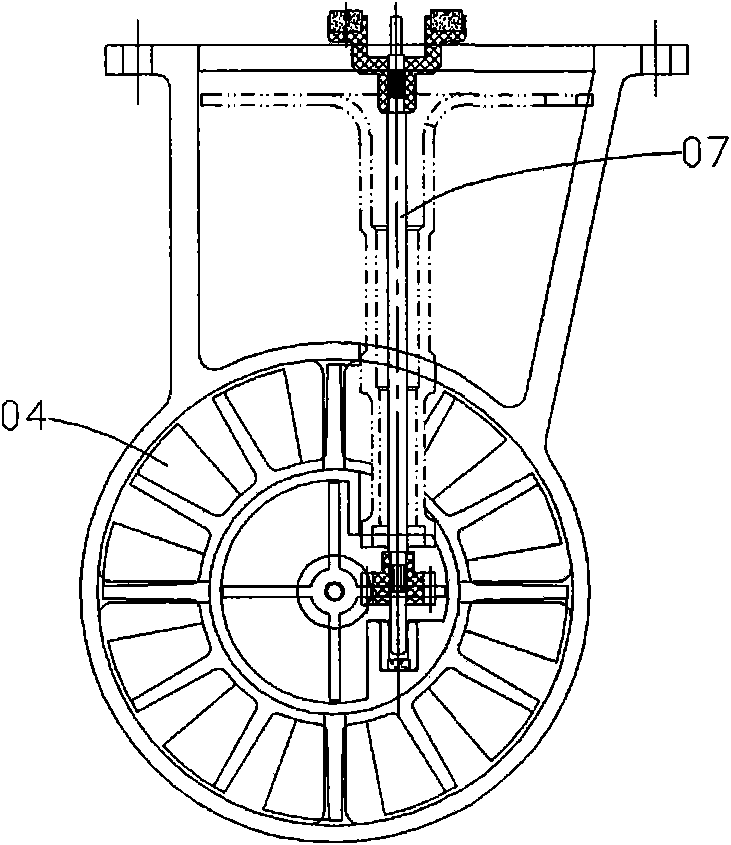

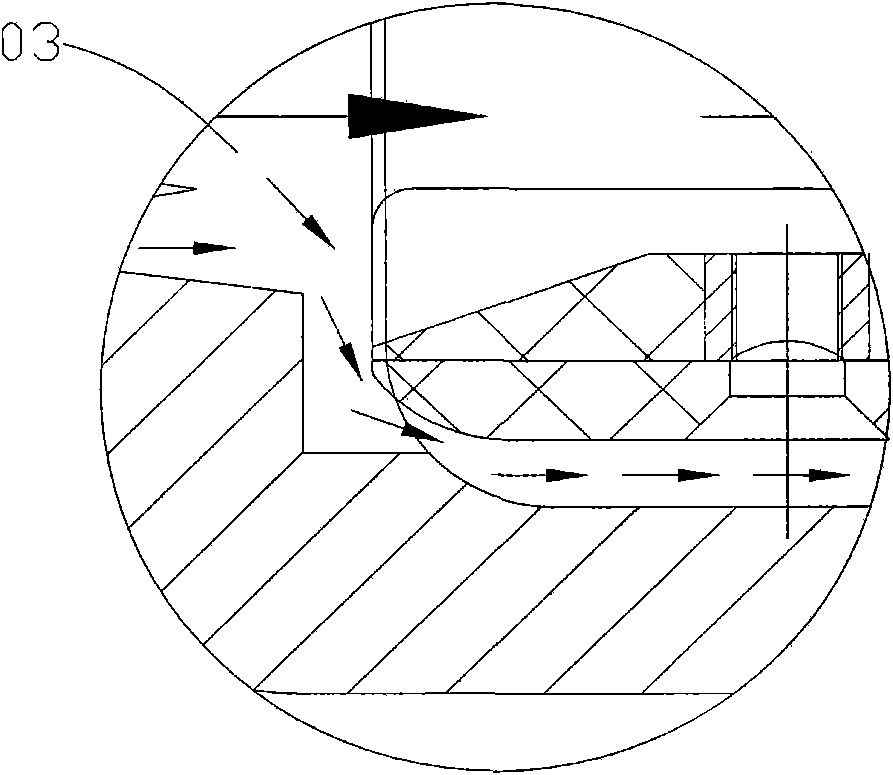

[0025] See Figure 4 and Figure 5 As shown: the improved spiral wing water meter of the present invention includes a housing 10 and a flange cover 20, wherein, the housing 10 is provided with a deflector 11, an impeller 12, and an impeller bracket 13, and the housing 10 is also provided with two sets of Adjustable rectifiers 30 , one set of adjustable rectifiers 30 is located between the deflector 11 and the impeller 12 , and the other set of adjustable rectifiers 30 is located at the rear end of the impeller support 13 . See Figure 5 and Figure 6 As shown: the adjustable rectifier 30 includes a rectifier main body 31, a plurality of movable blades 32, an adjustment connecting rod group 33, a transmission gear (including a bevel gear and a disc gear) 34, and a fixed blade 35, wherein the movable blade 32 and the fixed blade The vanes 35 are staggeredly distributed on the inner wall of the main body 31 of the rectifier, and the movable vanes 32 driven by the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com