Manufacturing method of photomask, photomask and manufacturing method of display device

A manufacturing method and photomask technology, which are applied in the direction of photolithography exposure device, microlithography exposure equipment, pattern surface photolithography technology, etc., can solve the problems of inability to read alignment marks, wrong recognition, the first main Insufficient coincidence accuracy of the pattern and the second pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

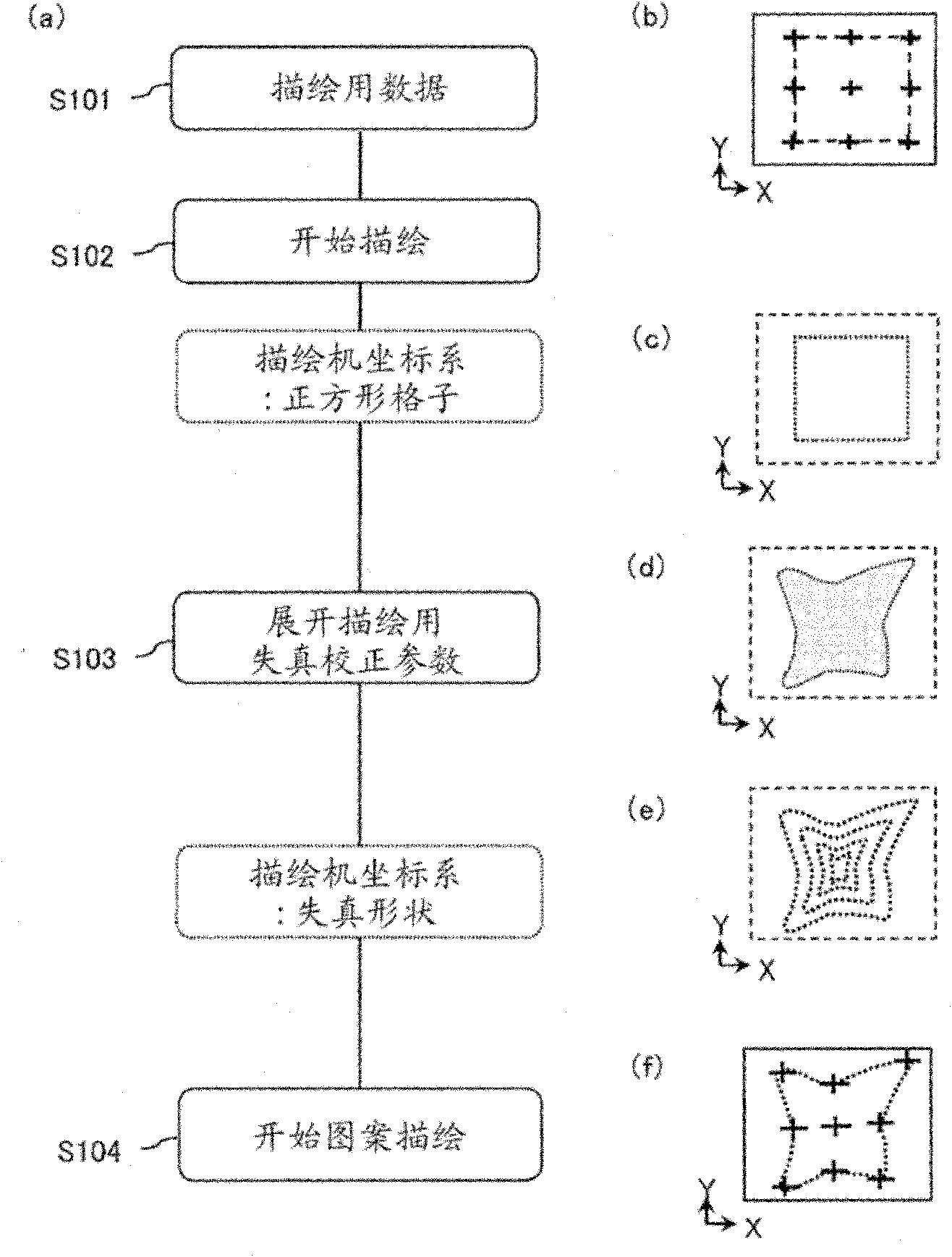

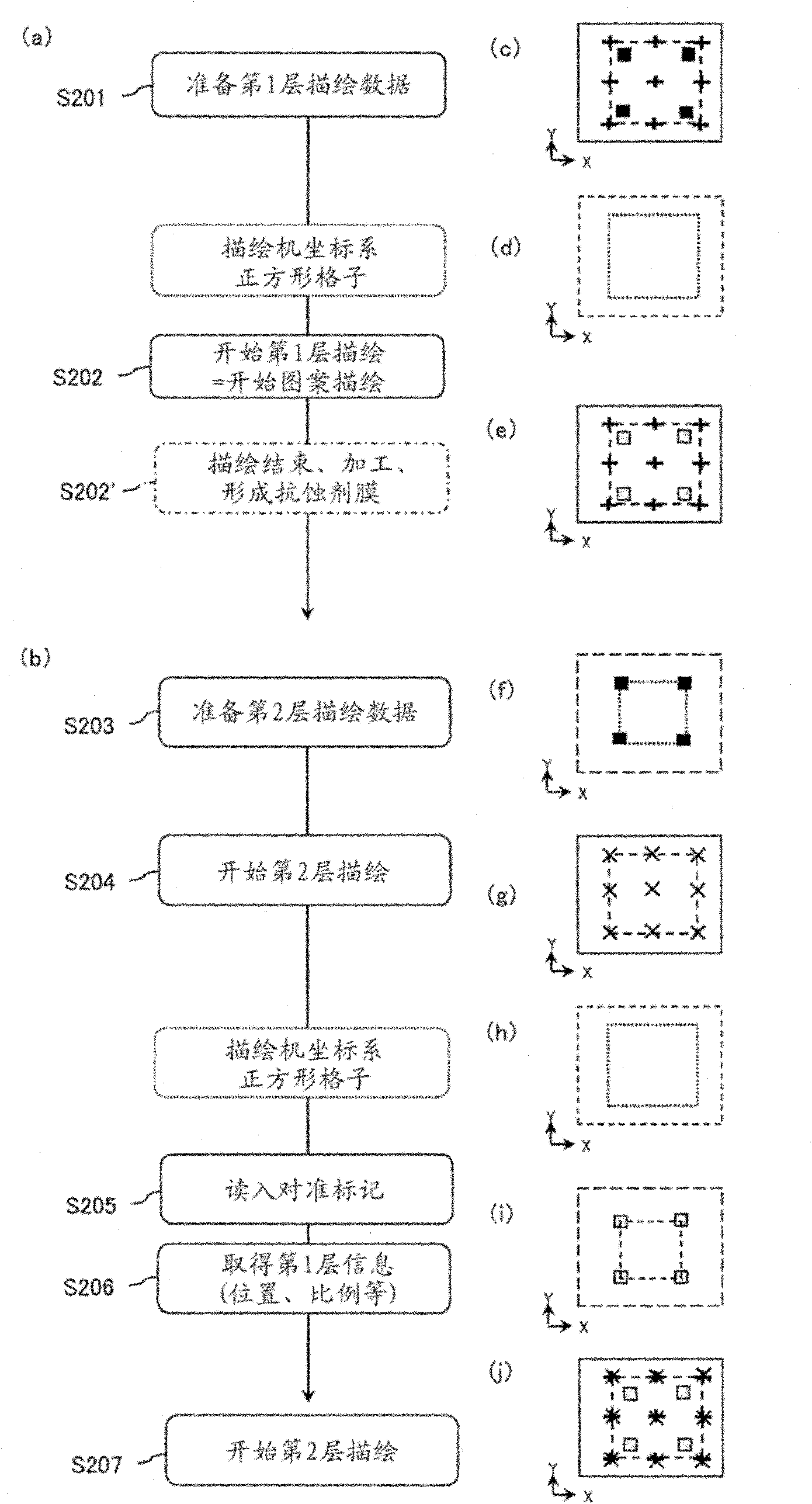

[0038] Below, the main reference Figure 7 , 3 4. The first embodiment of the present invention will be described. Figure 7 It is a flowchart of the manufacturing method of the multi-color photomask of this embodiment. image 3 It is a flowchart of the first drawing process of this embodiment, Figure 4 It is a flowchart of the second drawing process of this embodiment.

[0039] (1) Manufacturing method of multi-color photomask

[0040] First, refer to Figure 7 The outline of the manufacturing method of a multi-color photomask is demonstrated.

[0041] (Process of preparing mask blank)

[0042] A mask blank 100b is prepared in which a semi-transmissive film 111 as a second thin film and a light-shielding film 112 as a first thin film are sequentially formed on a transparent substrate 110 in advance ( Figure 7 (a)). In addition, a first resist film 133 made of, for example, a positive photoresist material is formed in advance on the light shielding film 112 .

[004...

no. 2 Embodiment approach

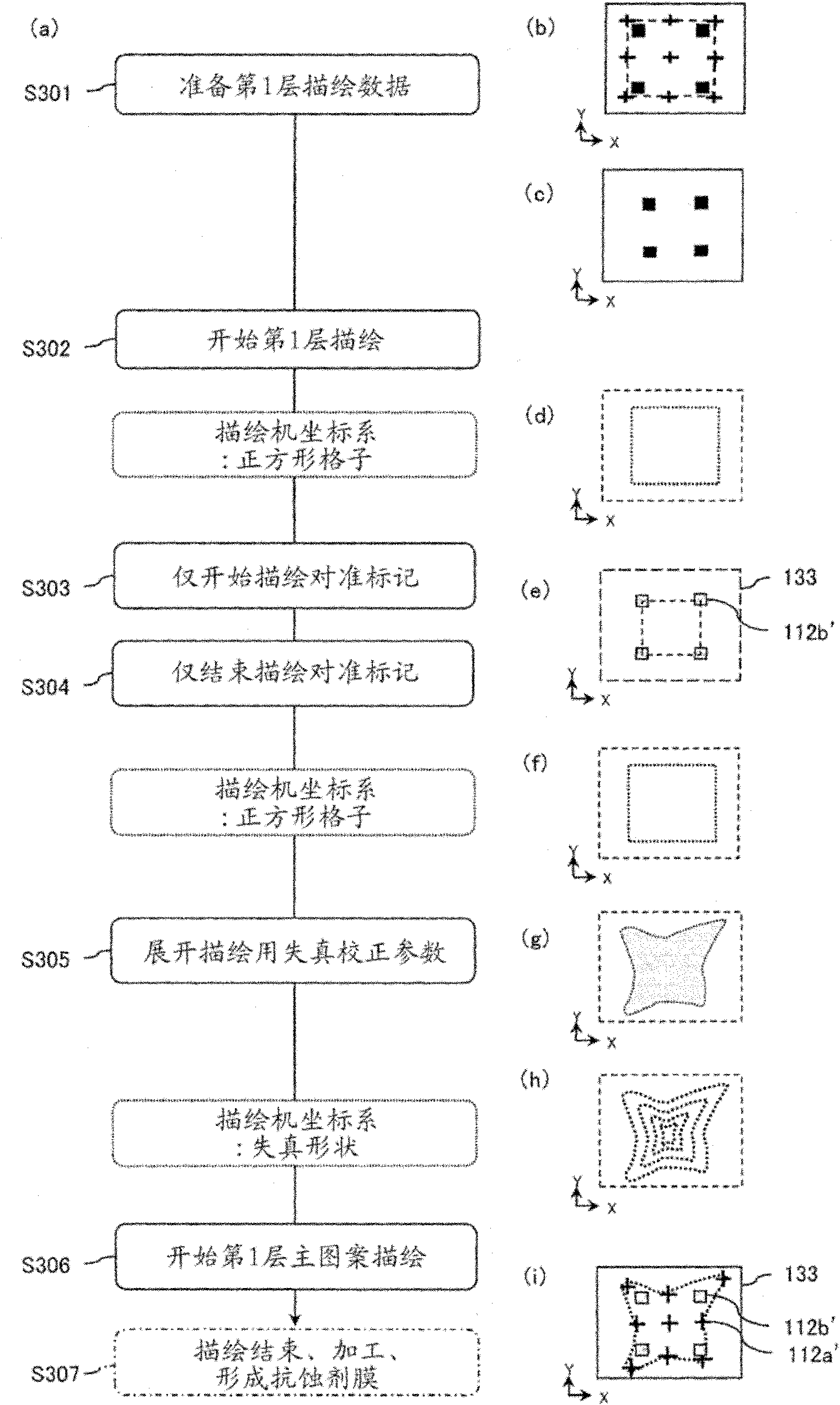

[0077]The first drawing step and the second drawing step of this embodiment are different from those of the first embodiment. Below, the main reference Figure 5 , 6 The drawing process of the present invention will be described. Figure 5 It is a flowchart of the first drawing process of this embodiment, Figure 6 It is a flowchart of the second drawing process of this embodiment.

[0078] (1st drawing process)

[0079] Such as Figure 5 As shown in (a), first, the first pattern data as the first layer drawing data is prepared (S501). Figure 5 (b) The structure of the 1st pattern data is illustrated. exist Figure 5 In (b), the alignment mark data is represented by - symbol, and the 1st main pattern data is represented by + symbol. In addition, in this embodiment, the drawing of the region 112 a ′ to be formed of the first main pattern and the drawing of the region 112 b ′ of an alignment mark to be formed are performed simultaneously. Therefore, the alignment mark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com