Igniter integrated lamp socket for hot re-strike of discharge lamp

A lamp socket and integrated point technology, which is applied in the field of ENSITY DISCHARGE LAMP" [agent case number N, can solve the problems of high cost and EMI interference of the instant start system, and achieve the effect of high flexibility, EMI reduction and EMI shielding reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

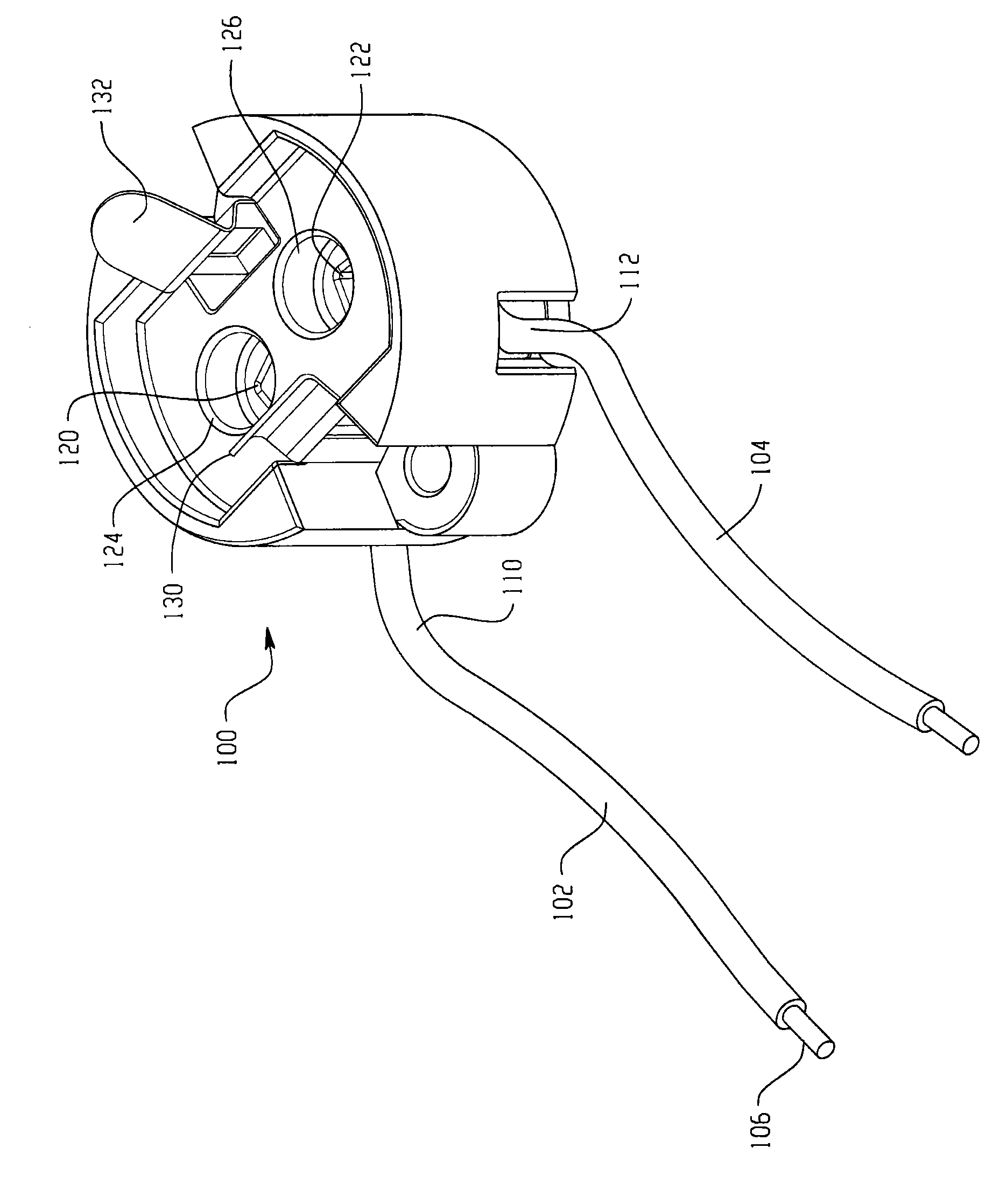

[0029] figure 1 Shown is a conventional lamp socket housing or base 100 typically used with a high intensity discharge (HID) lamp (not shown) in which the high intensity discharge lamp is removably retained. More specifically, the receptacle housing includes a first power cable 102 and a second power cable 104 having respective first ends 106, 108 that connect to an associated power source (not shown). Where the lamp assembly is intended for instant-start, hot-restart applications, the power cables 102, 104 are relatively high-power, high-voltage cables that are sufficiently insulated to transmit about tens of thousands of Volts and thus provide a volt ignition pulse of approximately twenty-five kilovolts (25kV) to thirty kilovolts (30kV) to the lamp received in the socket housing. Thus, the power cables run from a source that includes a ballast (not shown) and also a transformer that steps up the voltage from a level of a few hundred volts (below 1200 volts) to 25kV to 30kV....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com