Oxygen generator

A technology for oxygen generators and cabinets, applied in the field of oxygen generators, which can solve the problems of scattered structure of pressure swing adsorption oxygen generators, troublesome installation, storage and transportation, and gas can only be vented, so as to make full use of product gas and ensure regeneration effect , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

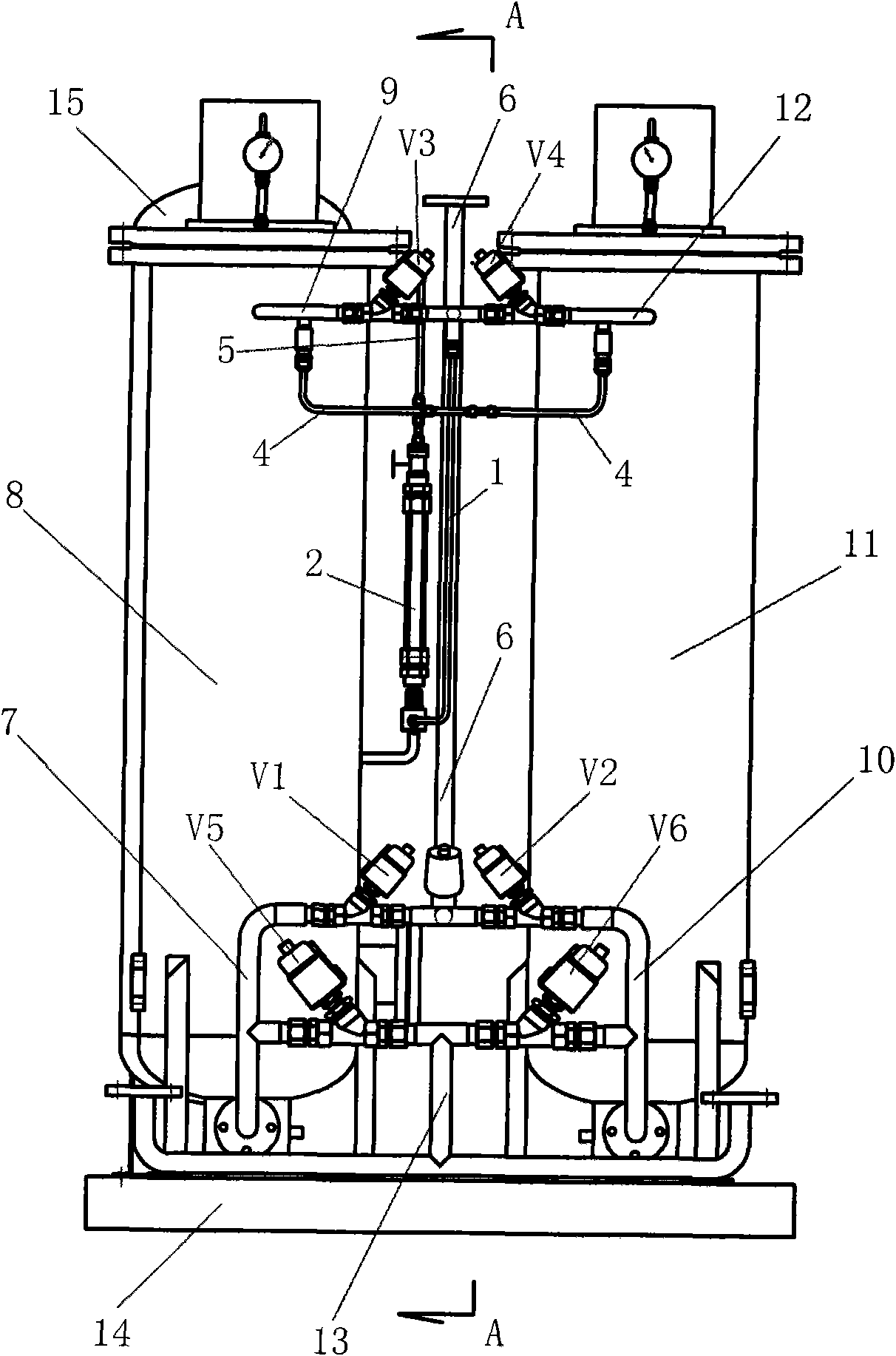

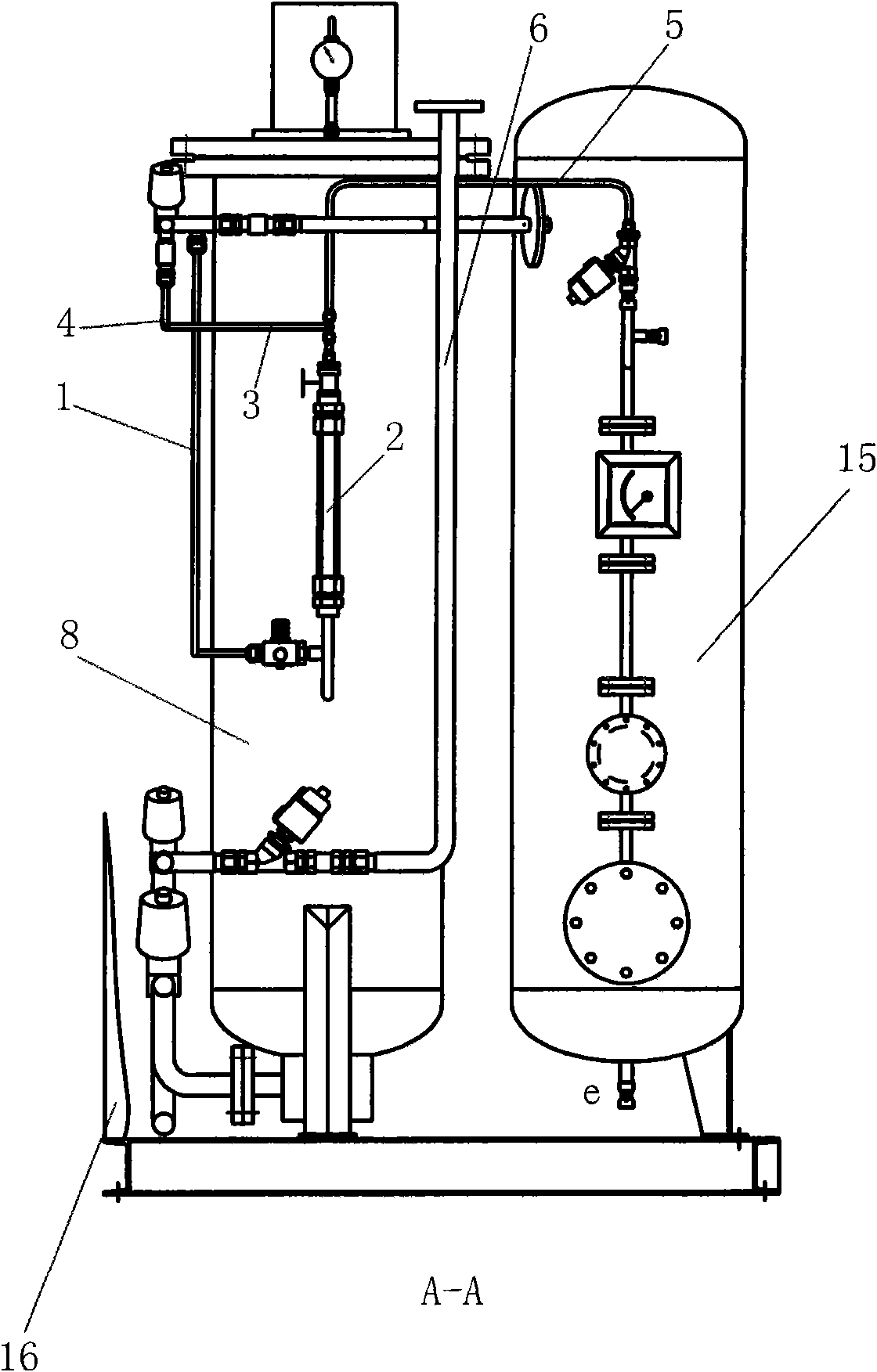

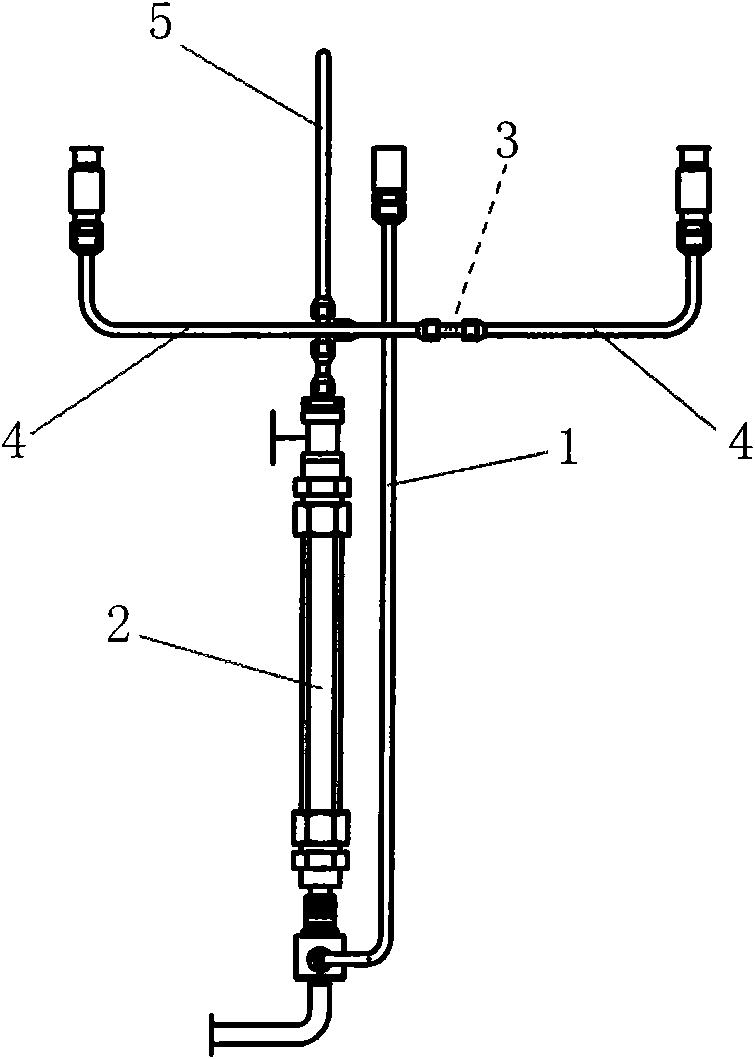

[0017] Oxygen generator, the base 14 in the cabinet 16 is provided with an adsorption tower A8, an adsorption tower B11, an air storage tank 15 and a silencer, the branch pipe A7 is connected to the bottom of the adsorption tower A, the branch pipe B10 is connected to the bottom of the adsorption tower B, and the branch pipe The other end of A and the other end of the branch pipe B are connected to each other, and the bottoms of the adsorption tower A and the adsorption tower B are respectively connected to the waste gas pipe 13 through the branch pipe A and the branch pipe B, and then connected to the silencer, and the adsorption tower A and the adsorption tower B The upper part is respectively connected to the air storage tank through the air outlet pipe A9 and the air outlet pipe B12. The branch pipe A is connected with the valve one V1, the branch pipe B is connected with the valve two V2, and the air outlet pipe A and the air outlet pipe B are respectively connected with V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com