Encoding method of battery pole piece forming machine

A technology of battery pole piece and coding method, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., which can solve the problems of cumbersome operation and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

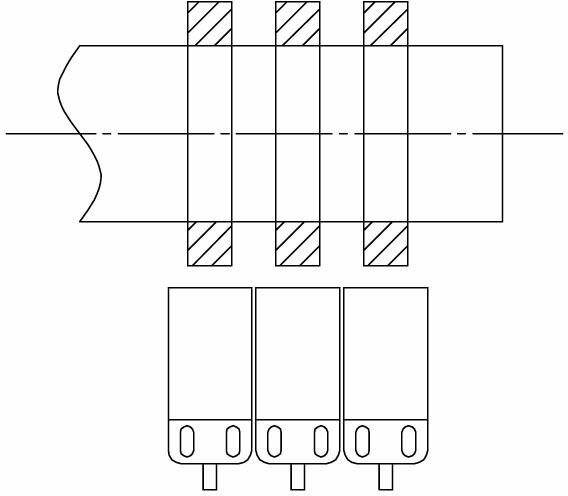

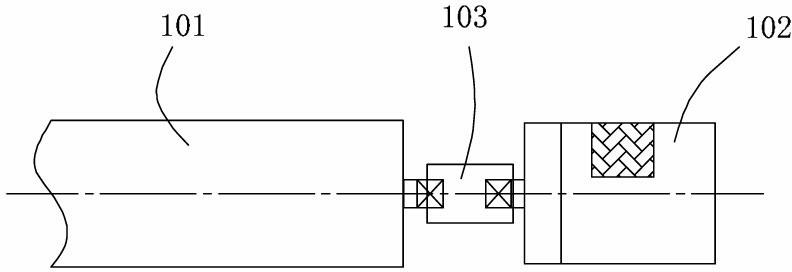

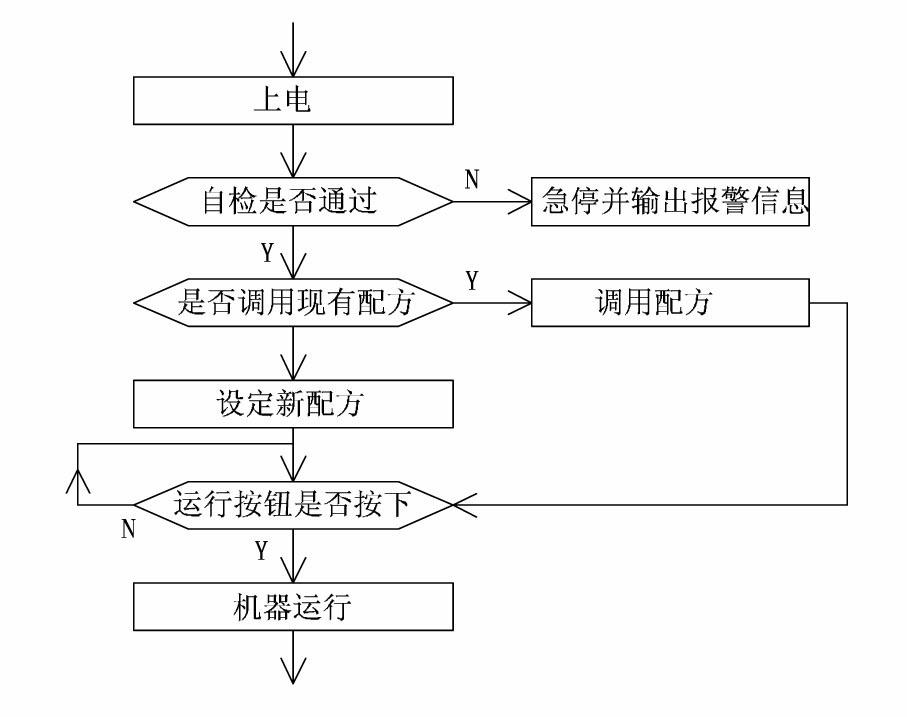

[0021] refer to figure 2 , image 3 , the first embodiment of the present invention is a coding method for a battery pole piece forming machine, the battery pole piece forming machine has a punching motor, the punching motor has an output spindle 101, and the battery pole piece forming machine also includes a For the material pulling motor, the output spindle is connected to a 360° absolute encoder 102 through a coupling 103, and the absolute position of the output spindle is transmitted back to the control system through the absolute encoder. The method includes the following steps: S10, power on; S20, self-inspection, If passed, turn to step S40; S30, emergency stop and output alarm information, the subroutine terminates; S40, choose whether to call the existing formula, if so, turn to step 80; S50, set a new formula; S60, judge whether the operation butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com