System maintenance time distribution method based on operation decomposition

A technology of maintenance time and distribution method, applied in the direction of instruments, etc., can solve problems such as unreasonable distribution of complex products, achieve the effect of reasonable maintenance distribution work, and improve applicability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

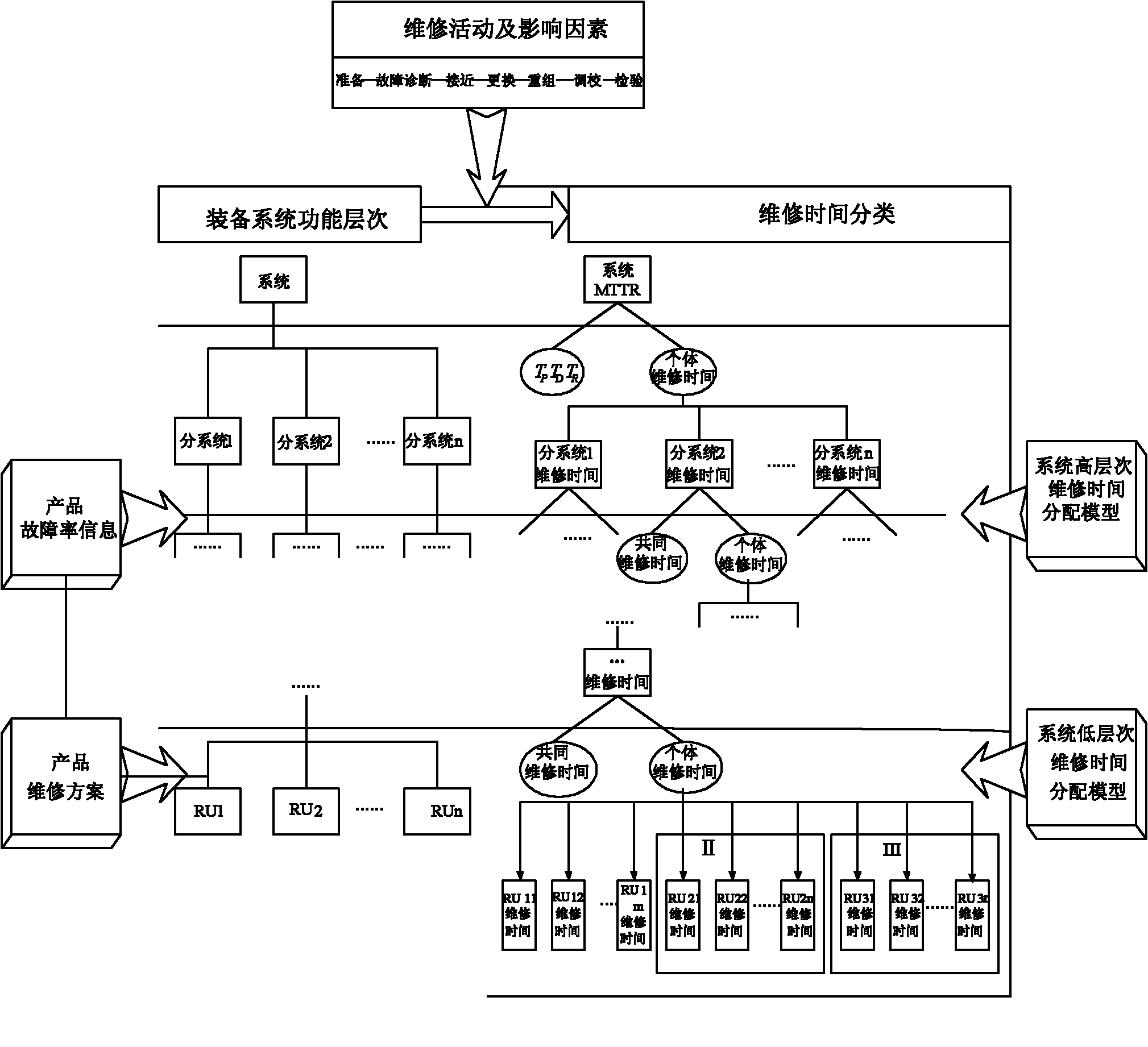

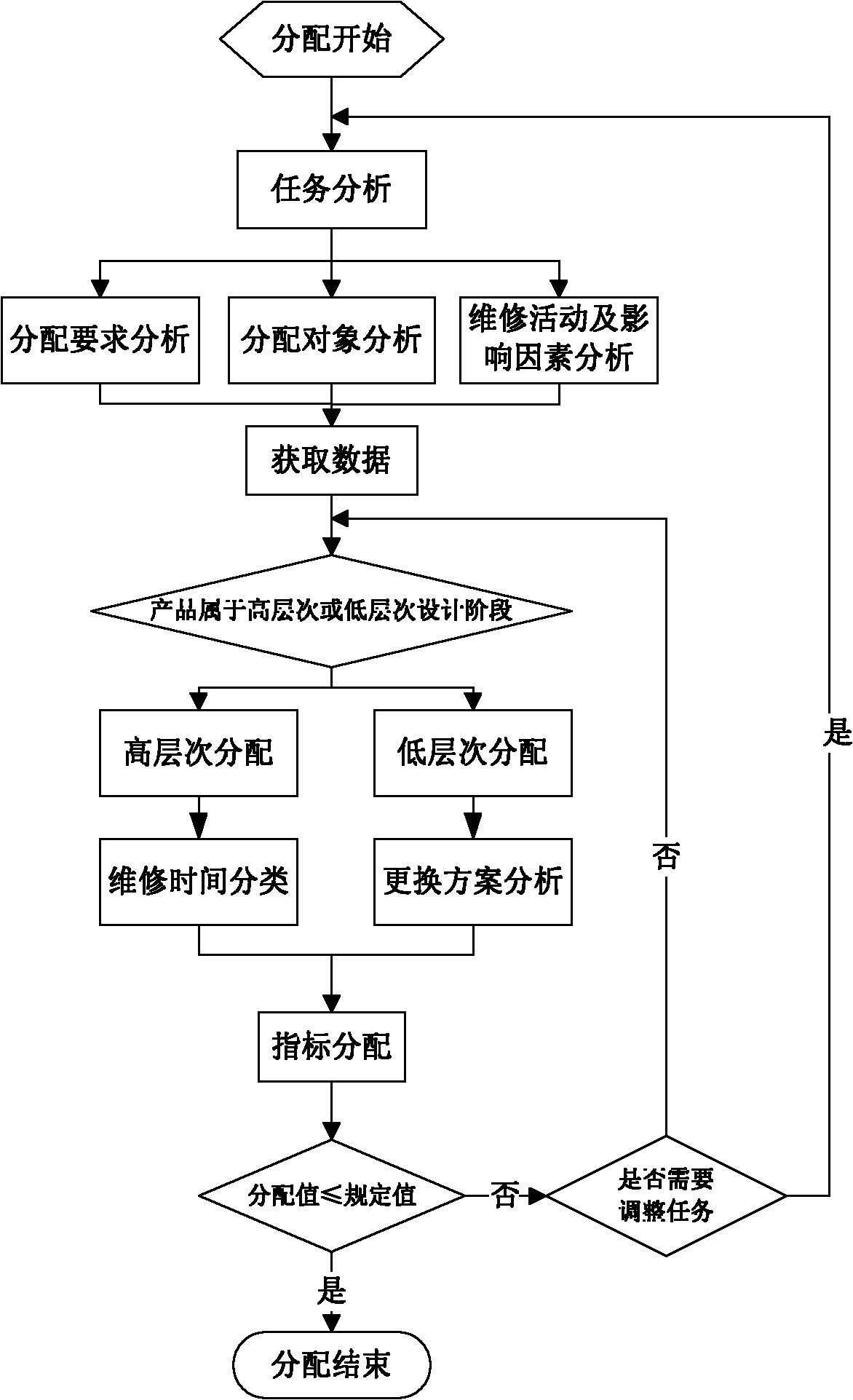

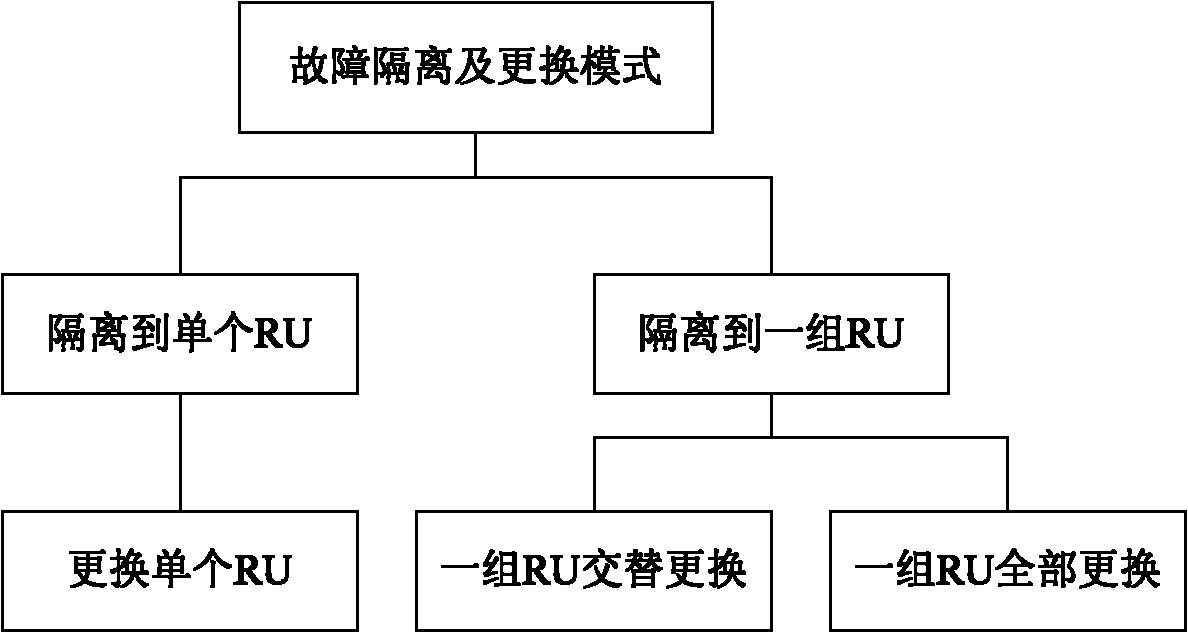

Method used

Image

Examples

Embodiment

[0136] This embodiment takes a Z system as an example. The main functions of the system are flight control, display control management, mission data loading and recording. It includes three subsystems: flight control system, display control system and mission computer. And the display and control sub-system includes 10 LRUs: management control computer 1, management control computer 2, multi-function display, central multi-function display, head-up display, avionics system start board, upper and front control board, integrated control board, lower display low voltage Power supply and low-voltage power supply The MTTR of the system, the failure rate and design characteristics of the three sub-systems and 10 LRUs are now known. It is required to use the maintenance allocation method based on the job decomposition system to determine the time index of the middle LRU of the display control sub-system.

[0137] This system fully considers maintainability when designing the scheme, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com