Friction welded steel piston having optimized cooling channel

A cooling channel, friction welding technology, applied in the direction of piston, machine/engine, mechanical equipment, etc., can solve the problems of reduced coolant exchange, affecting piston cooling, disadvantage, etc., and achieve the effect of preventing flow influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

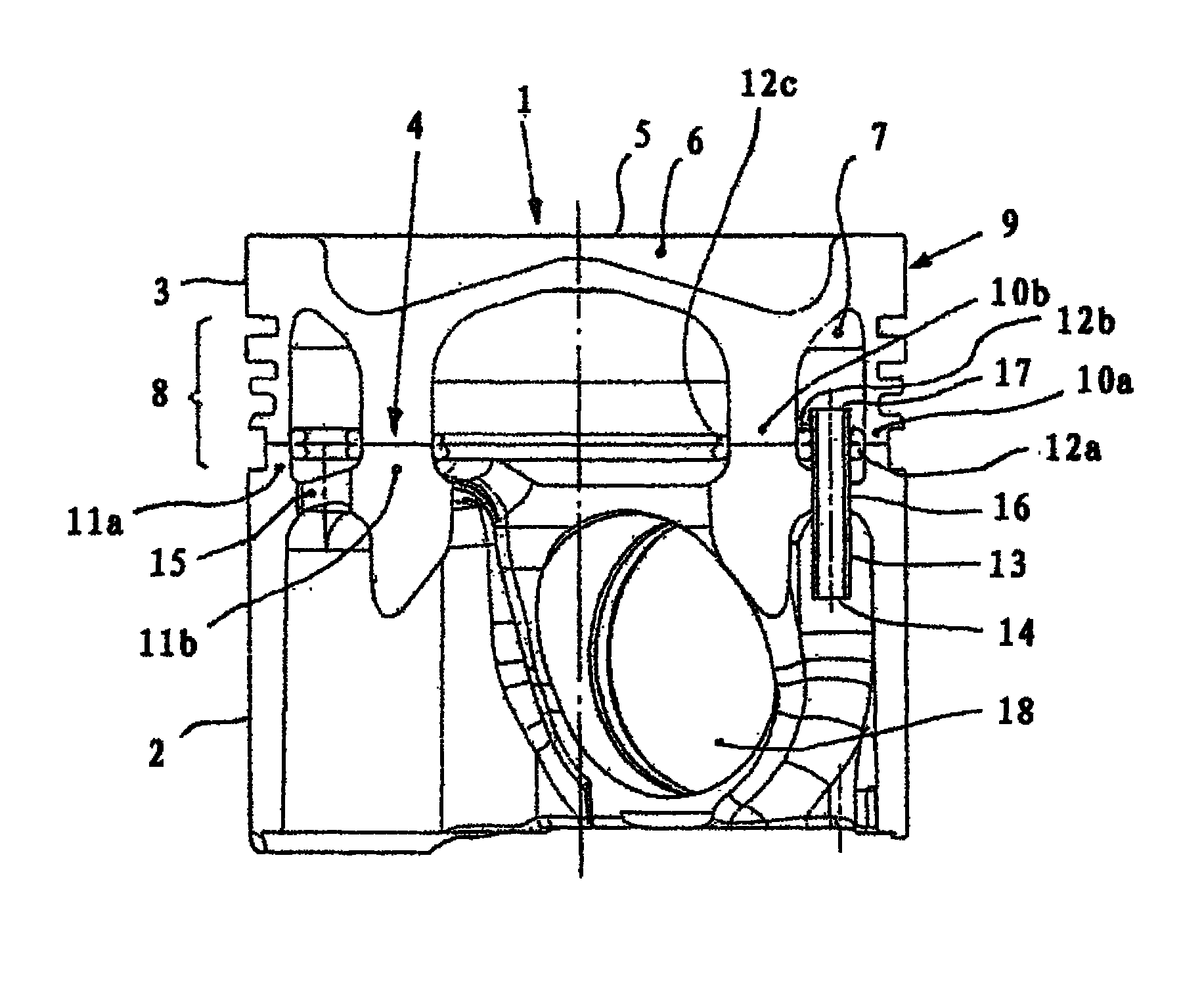

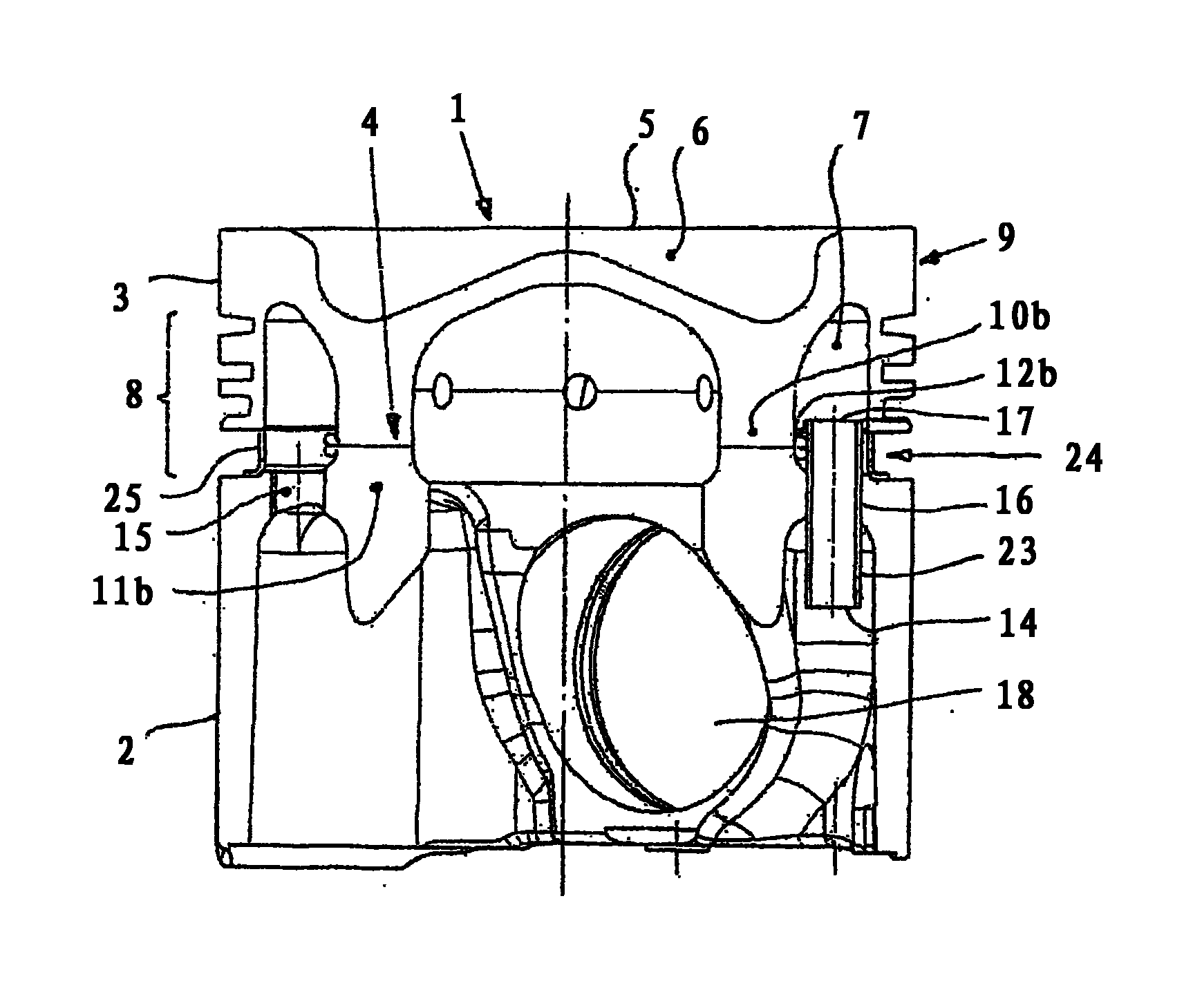

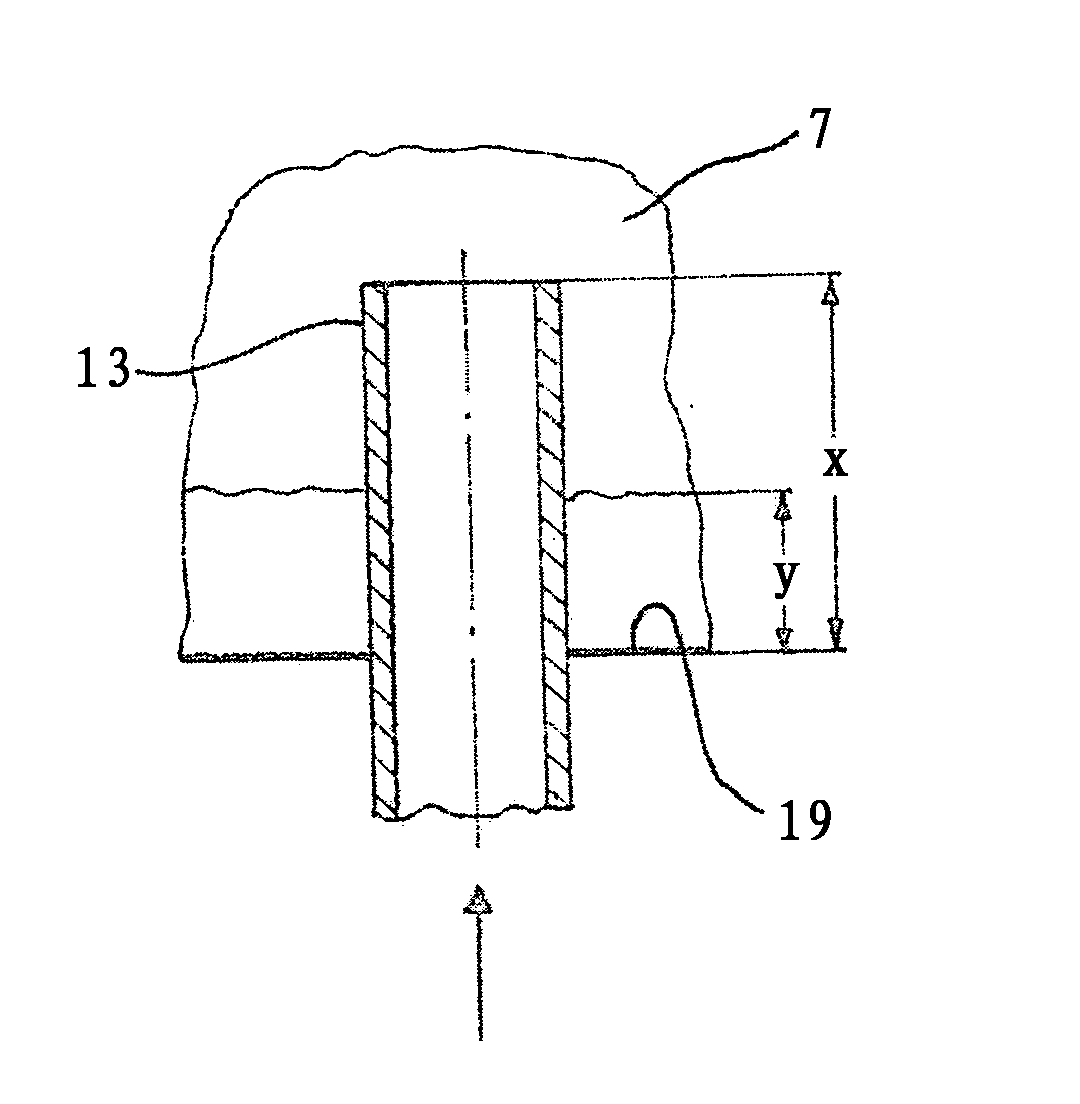

[0030] figure 1 A piston 1 is shown in half section, comprising a lower part 2 and an upper part 3 , which are joined together in the region of the contact geometry 4 by means of friction welding to form a structural unit. The upper part 3 of the piston 1 forms a combustion chamber cavity 6 in the region of the piston crown 5 . The ring-shaped cooling channel 7 integrated in the piston 1 extends from the upper part 3 into the lower part 2 and extends here at a radial distance from the piston ring region 8 , which is formed in the outer contour 9 . out. The upper part 3 comprises rotationally symmetrically extending, radially offset joint bridges 10 a , 10 b which, together with corresponding joint bridges 11 a , 11 b of the lower part 2 , form the contact geometry 4 . By means of friction welding, which is visible through the weld seam elevations 12a, 12b, 12c, the joining bridges 10a, 10b; 11a, 11b are materially connected in the region of the contact geometry 4 to create a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com