Flue gas condensation and dew formation acid fluid collection device for glass fiber reinforced plastic internal chimney

A flue gas condensation and collection device technology, applied in the field of electric power equipment, can solve the problems of chimney buildings and ecological environment damage, chimney acid rain, etc., and achieve the effect of simple structure, significant effect, and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

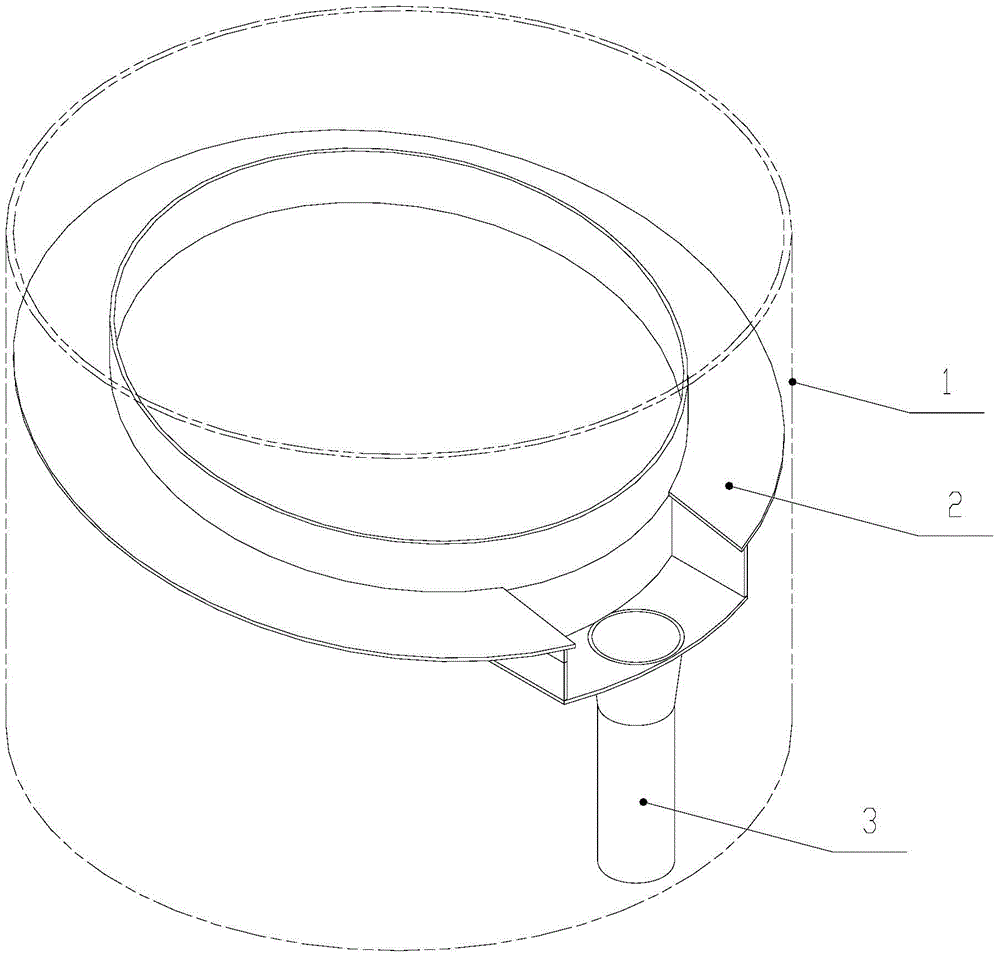

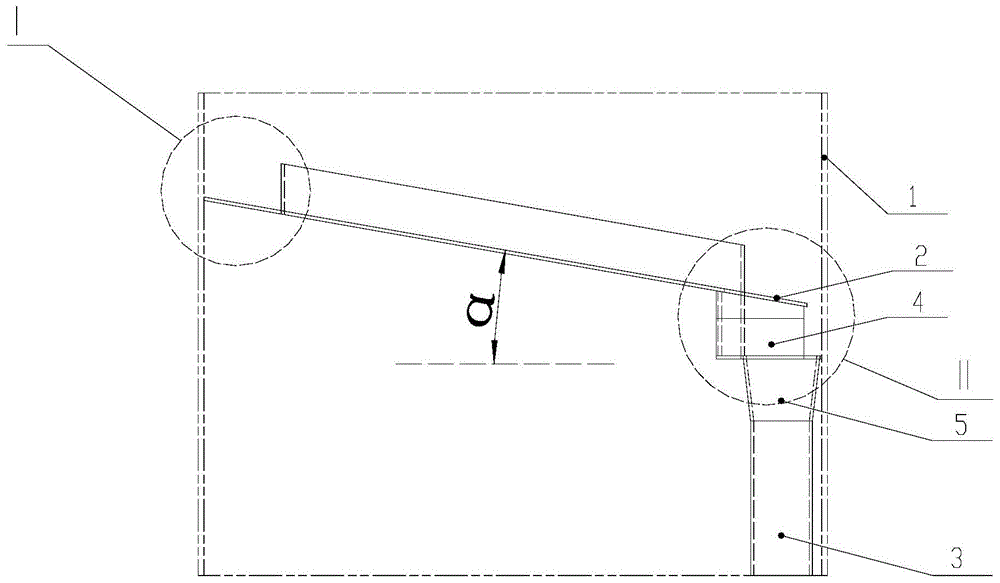

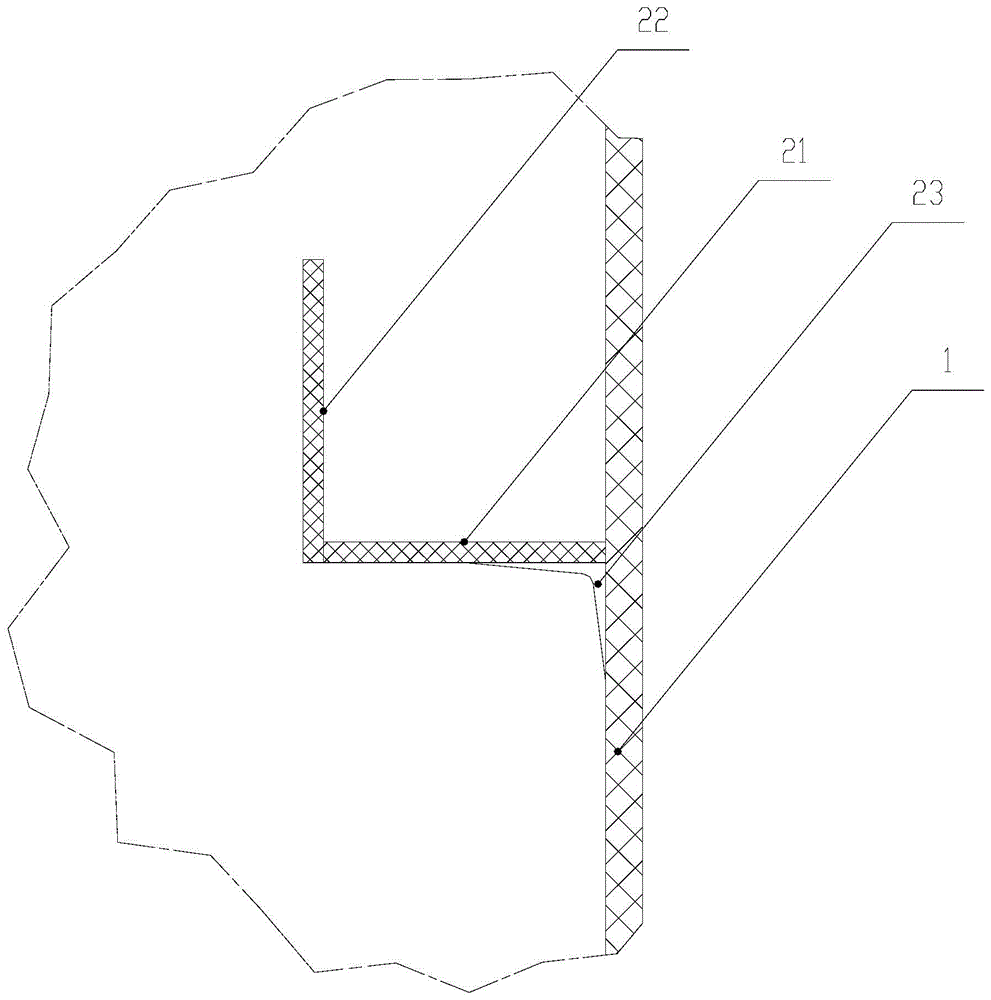

[0040] Such as Figure 1 to Figure 5 As shown, in this embodiment, the liquid collection tank 2 includes a ring-shaped bottom plate 21, and the bottom plate 21 is inclined at an acute angle α with the horizontal plane; the acute angle α is between 45 and 1 degree; preferably, α is 10 degrees. The outer periphery of the bottom plate 21 is fixed in contact with the inner wall of the glass fiber reinforced plastic cylinder 1, and the inner periphery is connected with a baffle plate 22 extending horizontally upwards to form a channel for flue gas condensation and acid liquid to flow. Preferably, the bottom plate 21 and the baffle plate 22 are both made of glass fiber reinforced plastic, and both are integrated.

[0041]Thus, the flue gas condensate and dew acid liquid along the inner wall of the chimney or freely falling will flow to the annular bottom plate, and the flue gas condensate and dew acid liquid will be collected under the joint action of the inner peripheral baffle an...

Embodiment 2

[0049] Such as Figure 6 and Figure 7 As shown, in this embodiment, the bottom plate 21 of the liquid collection tank 2 is in the shape of a cone that gradually slopes downward from the inner circumference to the outer circumference, and the outer circumference of the bottom plate 21 is in contact with the inner wall of the glass fiber reinforced plastic cylinder 1 to form a smoke supply. A conical channel through which gas condensation and acid liquid flow. The lower end of the bottom plate 21 is inclined at an acute angle α with the horizontal plane to ensure that the flue gas condensed and dew acid liquid in the liquid collection tank flows to the lowest point of the bottom plate under the joint restriction of the bottom plate and the inner wall of the chimney.

[0050] By setting the bottom plate into a tapered shape, the liquid collecting tank can be formed only by the bottom plate and the inner wall of the chimney, which simplifies the structure of the liquid collectin...

Embodiment 3

[0052] Such as Figure 8 As shown, in this embodiment, a ring-shaped liquid collection tank 2 is provided at different heights of the glass fiber reinforced plastic inner chimney, and the inclination direction of each liquid collection tank 2 is consistent, so that the lowest points of each liquid collection tank 2 are in the same vertical position. on-line.

[0053] In this embodiment, the glass fiber reinforced plastic inner chimney is in the shape of a cone that gradually widens from top to bottom, and the width of the bottom plate 21 of each liquid collection tank 2 gradually widens from top to bottom, so that each liquid collection tank 2 can be placed on different vertical surfaces. The flue gas condensate and dew acid liquid is collected, and the lower liquid collection tank 2 can collect the flue gas condensate and dew acid liquid overflowing from the liquid discharge tank 4 corresponding to the upper liquid collection tank 2, so as to realize the liquid collection Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com