Flock filling machine

A down filling machine and down box technology, applied in the field of down filling machines, can solve the problems of high price, difficult maintenance, and high equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the present invention, the following describes the down filling machine provided by the present invention in conjunction with embodiments, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

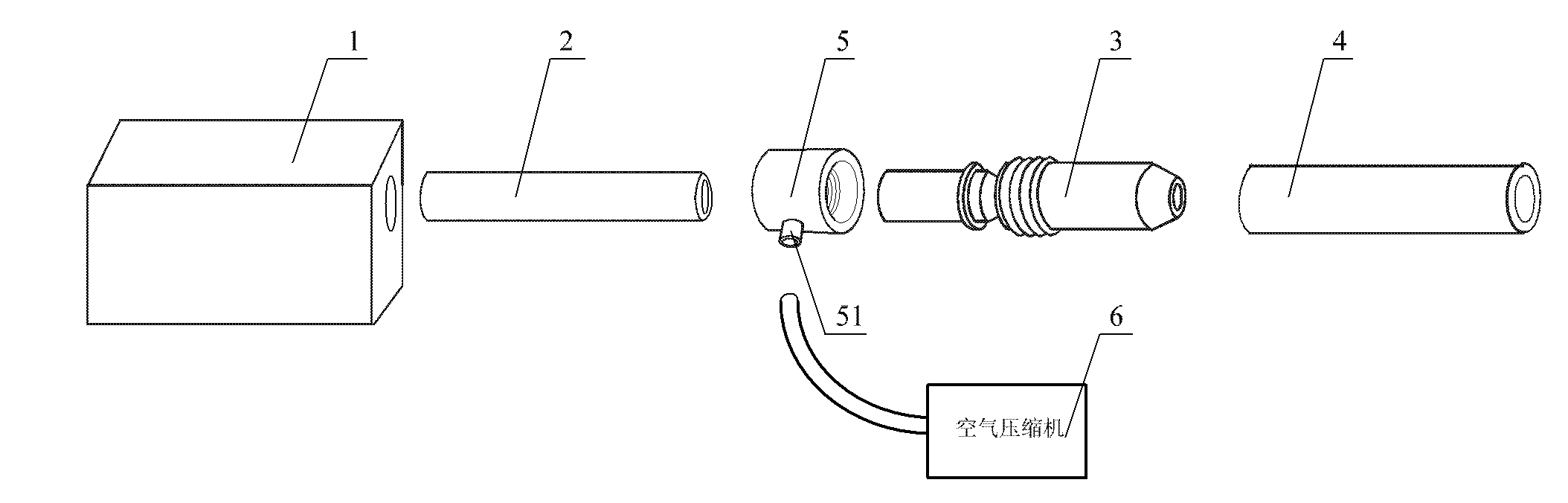

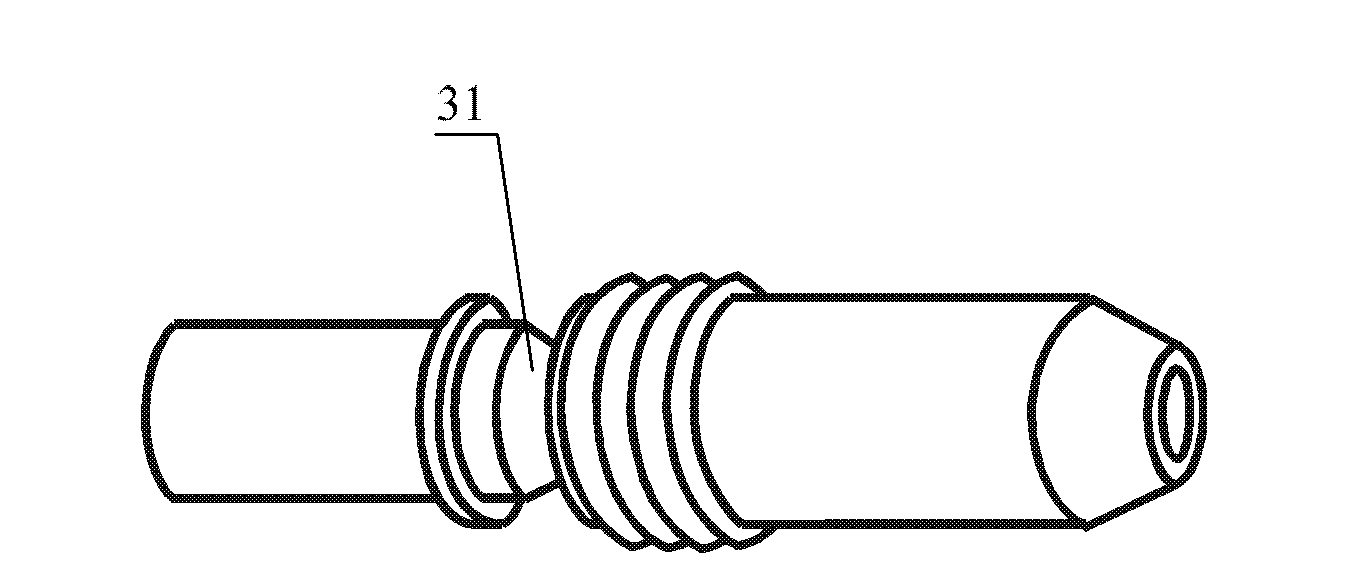

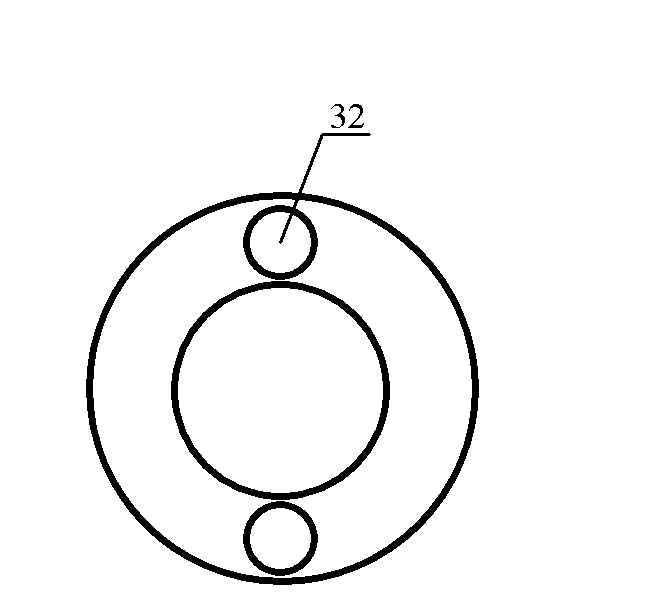

[0028] The embodiment of the invention discloses a down filling machine, such as figure 1 Shown is an exploded schematic diagram of the structure of the down filling machine provided in Embodiment 1 of the present invention. The down filling machine provided in this embodiment includes: a down filling box 1, a suction pipe 2, a connecting pipe 3, a filling pipe 4, a tee 5 and air Compressor 6, where:

[0029] The down loading box 1 is used to hold down and is connected with the suction pipe 2;

[0030] The suction pipe 2 is connected to the filling pipe 4 through the connecting pipe 3. When in use, the filling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com