Variable flow sprayer nozzle

A nozzle and flow technology of nozzles, applied in the direction of spraying devices, spraying devices, etc., can solve problems such as labor-intensive and inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

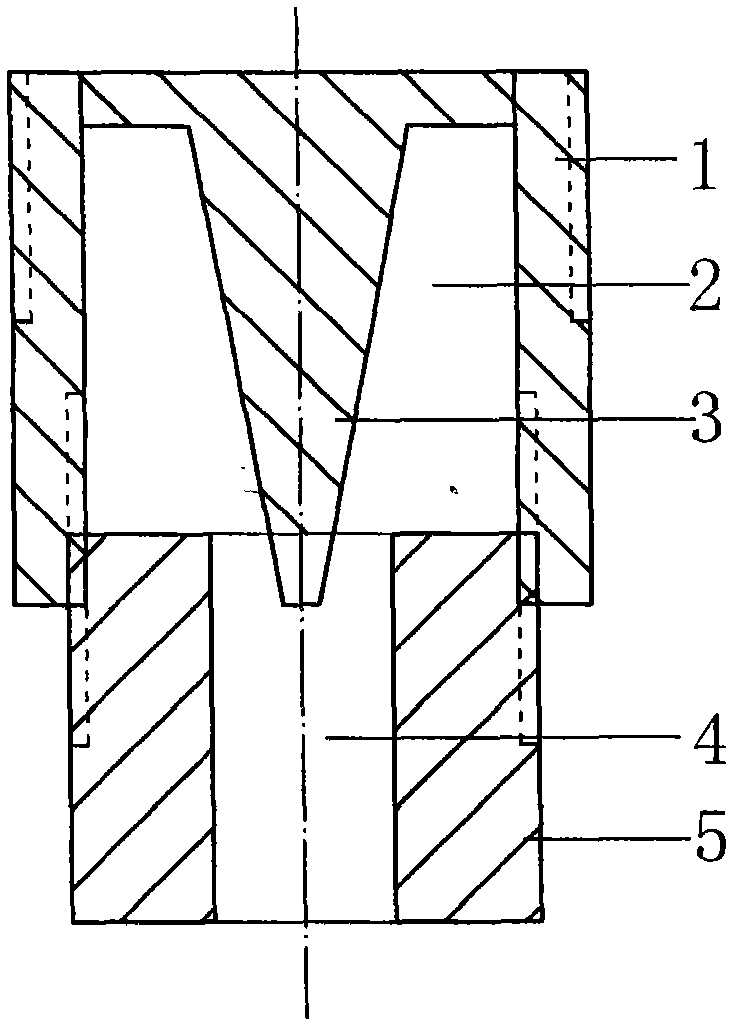

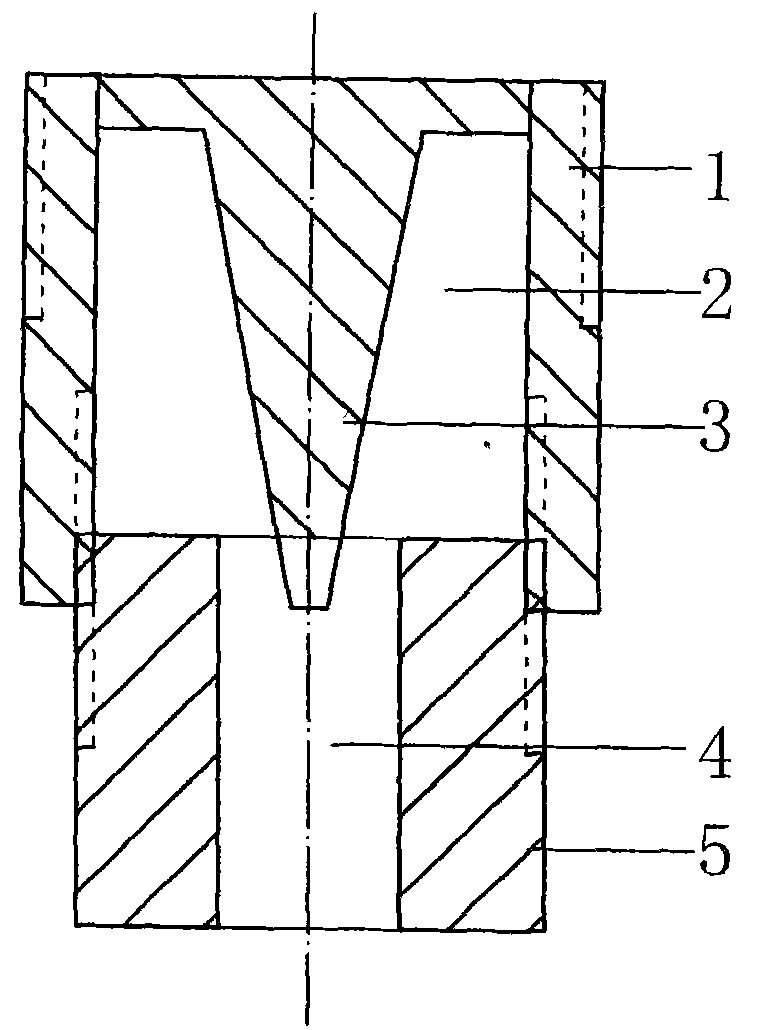

[0005] The present invention will be described in detail in conjunction with the following embodiments. The spray head nozzle includes an upper casing 1 and a lower casing 5. The lower casing is provided with an axial water spray hole 4. There is a circumferentially open end plate at the top of the upper casing. The center of the end plate is provided with a downward cone 3 placed in the upper port of the water spray hole of the lower housing, and the external thread on the upper part of the upper housing matches the threaded hole of the shower head.

[0006] The principle and operation method of adjusting the flow rate of the nozzle of the variable flow nozzle of the present invention is that when the spray irrigation flow needs to be increased, the lower housing is rotated counterclockwise by hand, that is, the lower housing moves downward from the upper housing. At this time, the upper housing The cone moves upward from the water spray hole of the lower shell, the flow area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com