Resin sand and foam plastic pattern casting method

A technology of foam plastic and resin sand, which is applied in the field of resin sand foam plastic mold casting, can solve the problems of prolonging the process flow and consuming a lot of time, and achieve the effect of reducing cost, saving cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

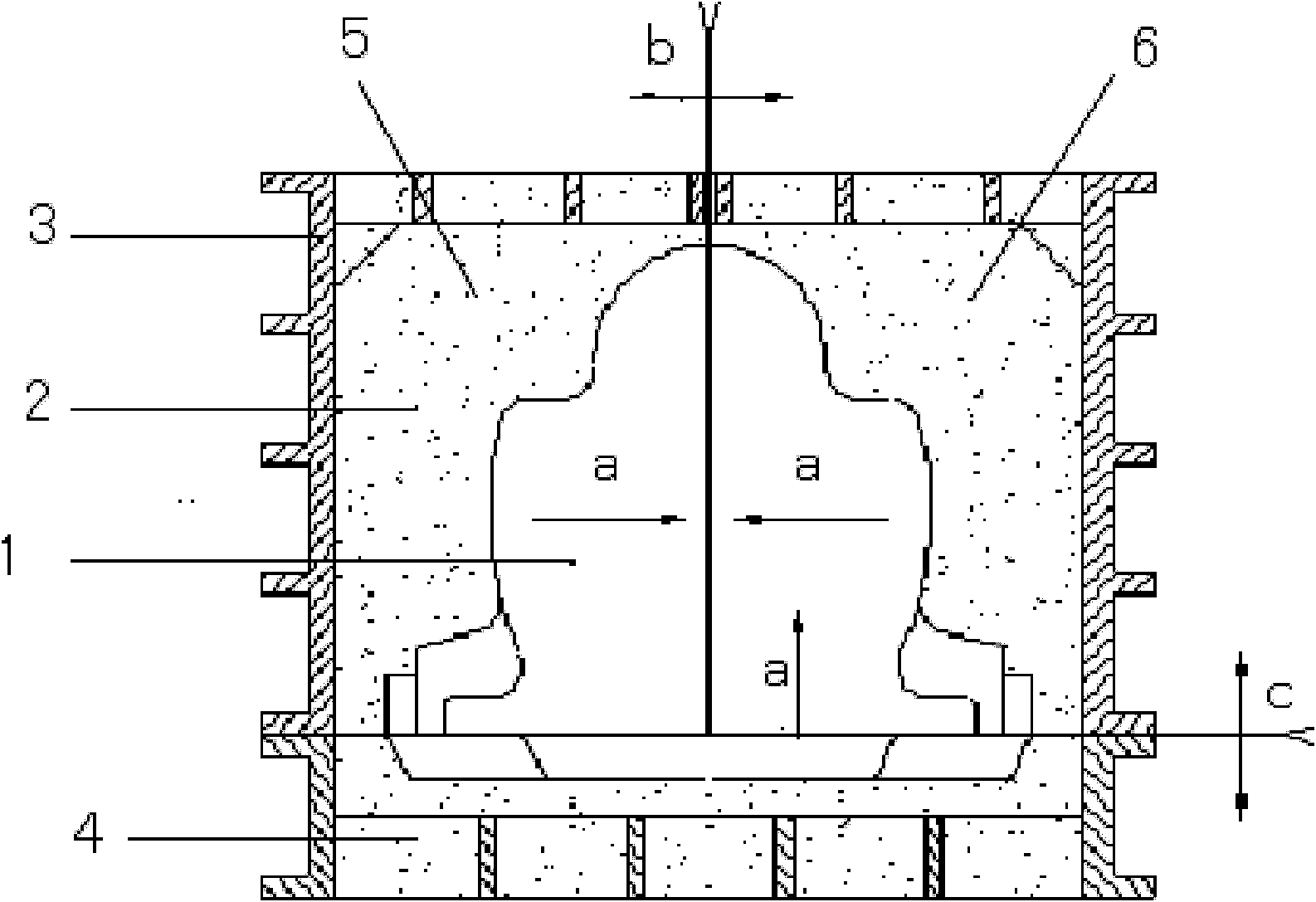

[0040] like figure 1 As shown, the foundry flask provided in this embodiment includes: a cavity 1, resin sand 2, an outer wall of the flask 3, a lower flask 4, a left flask 5, and a right flask 6; direction.

[0041] Prepared using Styrofoam such as figure 1 The water pump pattern shown in the middle cavity 1, take the mold and apply water-based paint on the surface of the cavity. First place the pattern in the lower flask 4, fill with resin sand, bond and compact with a binder, set the runner, place the left flask 5 and the right flask 6 above the lower flask and close together along the parting surface. Fill the resin sand with adhesive and compact it, and set the gate. Make a sign at the sandbox junction. Open the sand box along the moulding directions a, b, and c to take out the pattern, apply fire-resistant paint on the surface of the cavity, and then re-close the box according to the mark of the sand box after the paint is dry.

[0042] The metal melt is injected fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractory temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com