Corner cutting control method in cutting processing system

A technology of cutting processing and control method, which is applied in the cutting processing control of CNC machine tools and in the field of CNC machine tool control. It can solve the problems of affecting the smoothness of the cutting place, failing to achieve effective methods, and over-burning at corners, so as to avoid over-burning and discoloration. Phenomenon, simple application method, and output reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

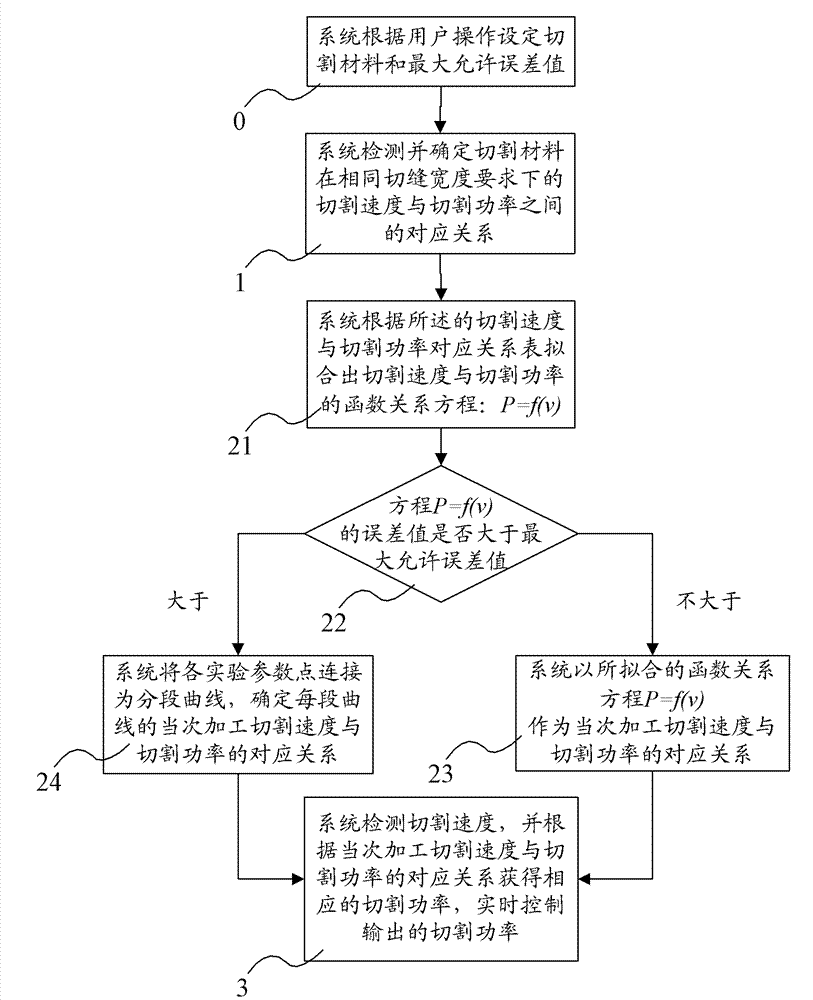

[0030] see figure 1 Shown is a flow chart of the steps of the corner cutting control method in the cutting processing system of the present invention.

[0031] In one embodiment of the present invention, described method specifically comprises the following steps:

[0032] (0) The system sets the cutting material and the maximum allowable error value according to the user's operation;

[0033] (1) The system detects and determines the corresponding relationship between the cutting speed and the cutting power of the cutting material under the same kerf width requirement;

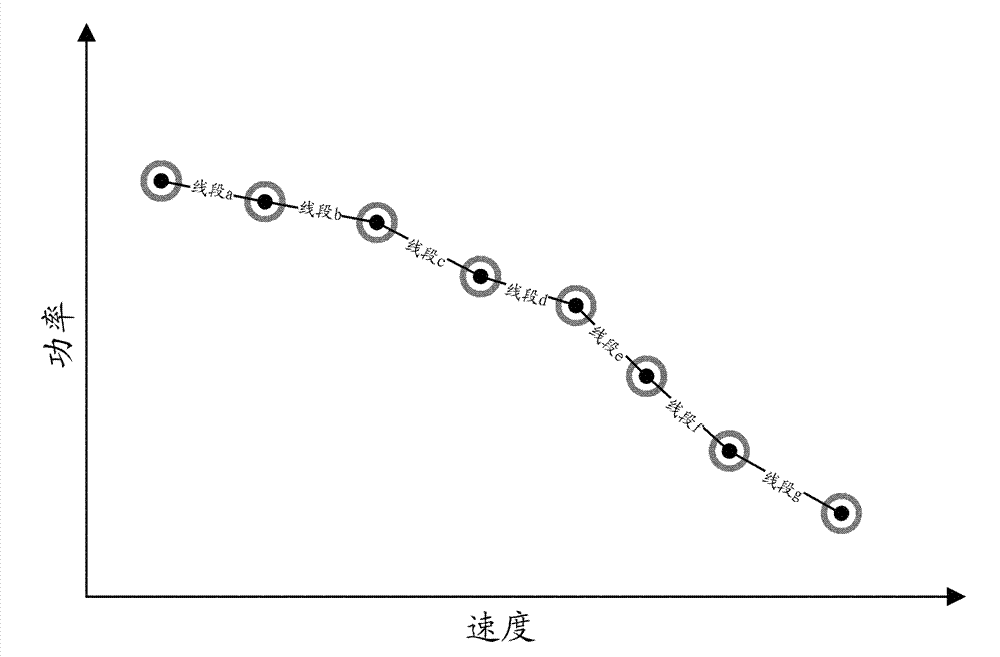

[0034] (2) The system determines the corresponding relationship between the cutting speed and cutting power for the current processing according to the corresponding relationship between the cutting speed and the cutting power and the maximum allowable error value;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com