Parallel-connection type hydraulic-electro hybrid power driving system

A hybrid and drive system technology, applied in hybrid vehicles, power plants, electric vehicles, etc., can solve the problem that energy storage devices are difficult to meet the requirements of high power density and high energy density, low braking energy recovery rate, and the use of components. Short life and other problems, to achieve the effect of solving the difficulty of instantaneous charging and discharging of large current, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

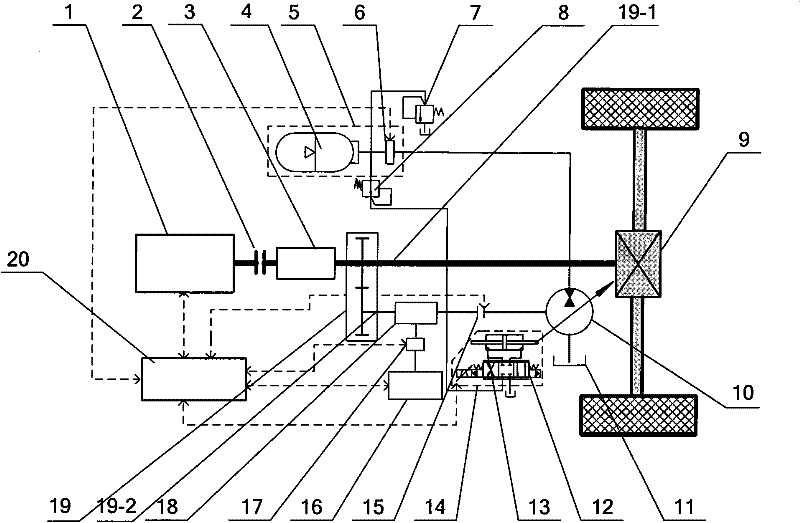

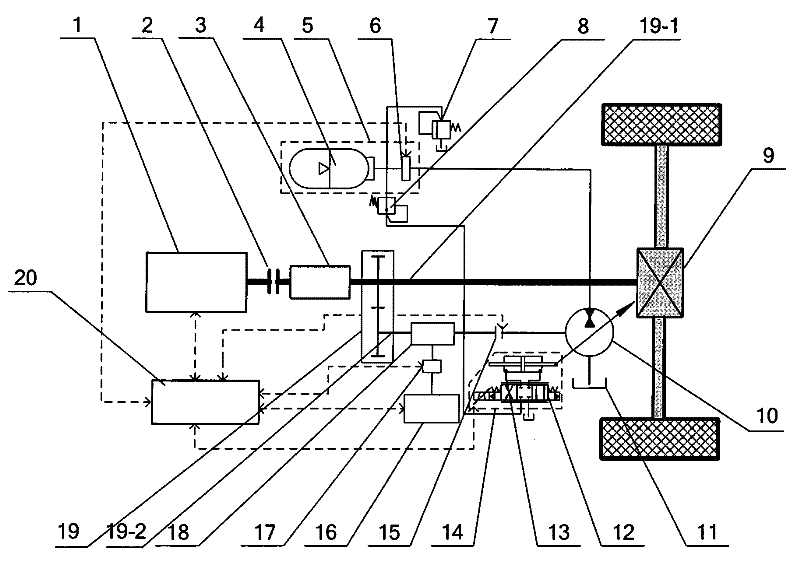

[0020] Embodiment 1: The power drive system includes an engine 1, a clutch 2, a transmission 3, a high-pressure hydraulic energy storage 4, a hydraulic accumulator assembly 5, a two-position two-way electro-hydraulic reversing valve 6, an overflow valve 7, and a pressure reducing valve 8 , drive axle 9, hydraulic pump / motor 10, fuel tank 11, electro-hydraulic servo 12, variable cylinder 13, hydraulic pump / motor control assembly 14, electromagnetic clutch 15, battery 16, inverter 17, motor 18, torque coupler 19 and central controller 20;

[0021]The engine 1 is mechanically connected to the clutch 2 and the transmission 3 in turn, the input shaft of the torque coupling 19 is mechanically connected to the output shaft of the transmission 3, the first output shaft 19-1 of the torque coupling 19 is mechanically connected to one end of the transmission shaft, and the other end of the transmission shaft It is connected with the input end of drive axle 9, the second output shaft 19-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com