Grinding processing method and device for online grinding wheel dressing by ultrasonic vibration and

A grinding wheel dressing and ultrasonic vibration technology is applied in the field of grinding processing, which can solve the problems of wasting time and materials, affecting the precision machining accuracy of grinding wheels, and processing discontinuity, and achieves a simple structure, does not affect work efficiency, and is easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

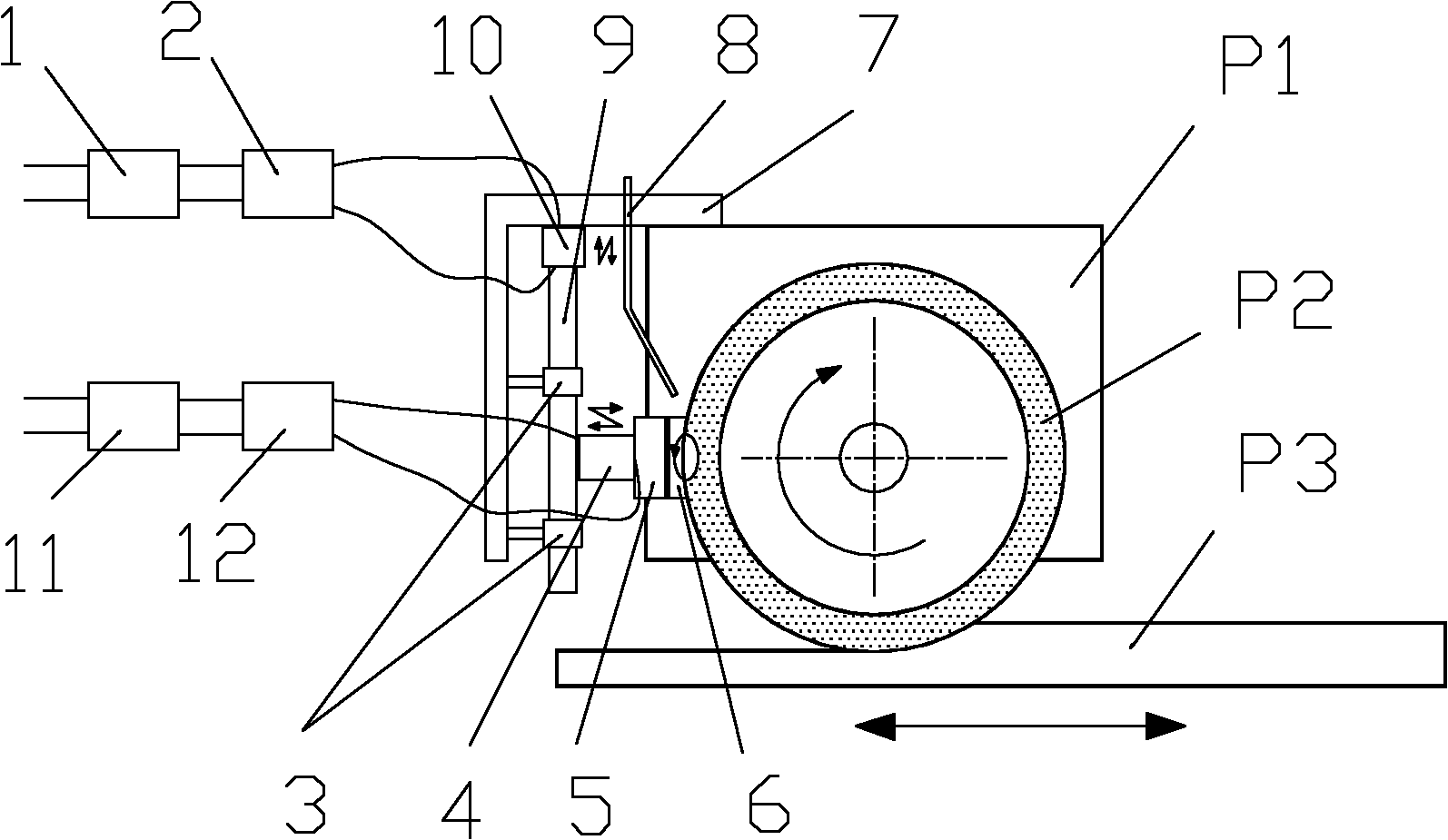

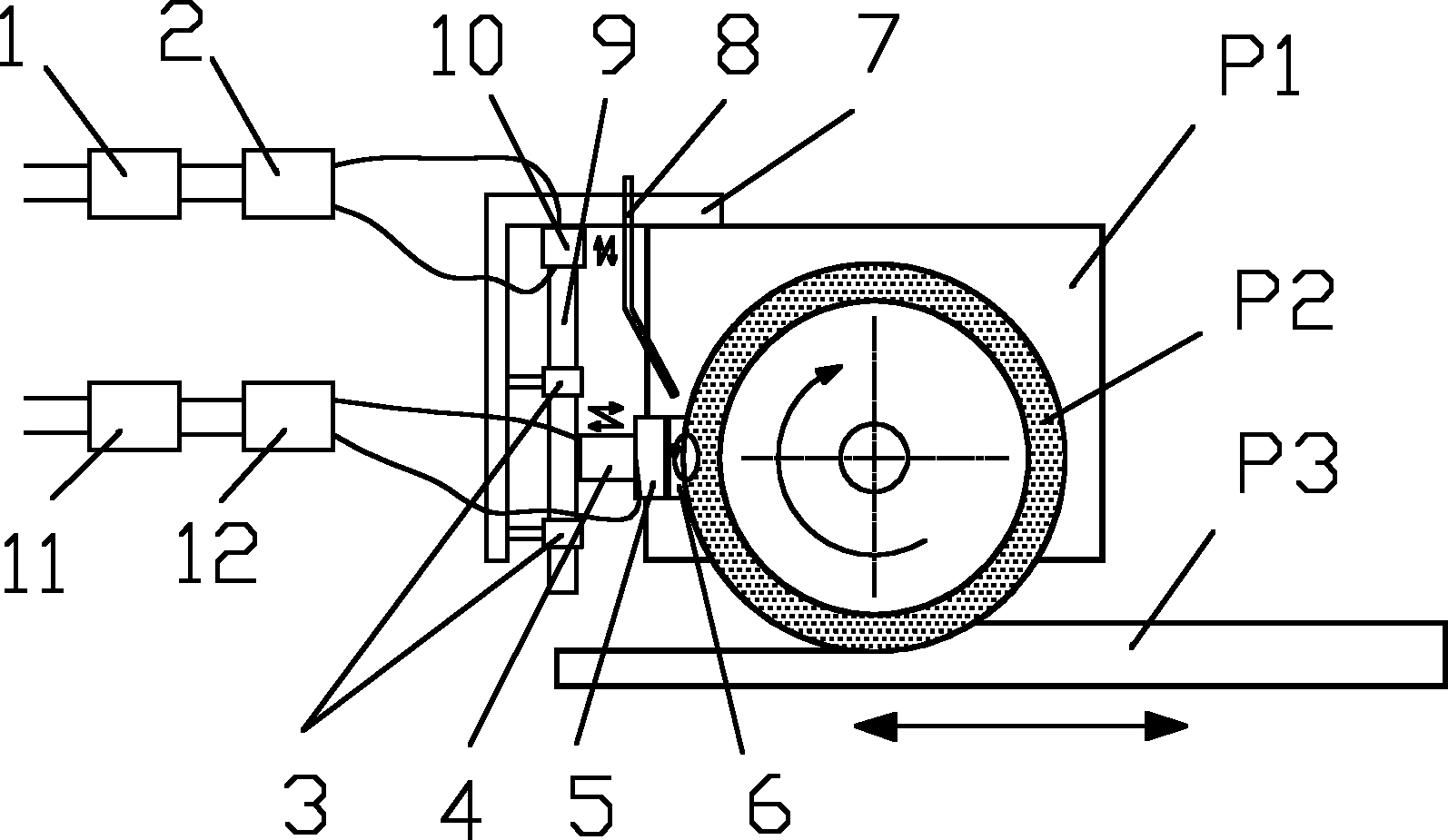

[0017] see figure 1 , the embodiment of the ultrasonic vibration online grinding wheel dressing device of the present invention is provided with a bracket 7, a vibration shaft 9, a longitudinal piezoelectric ceramic 10, a transverse piezoelectric ceramic 4, a trimming block 6, a trimming block support 5, a coolant nozzle 8, A first wave function generator 1 , a first power amplifier 2 , a second wave function generator 11 and a second power amplifier 12 . The vibration shaft 9 is installed on the bracket 7 through the bearing 3, and the longitudinal piezoelectric ceramic 10 is axially connected with the upper end of the vibration shaft 9, and the longitudinal piezoelectric ceramic 10 and the vibration shaft 9 are coaxial. The transverse piezoelectric ceramic 4 is radially connected to the vibration axis 9, and the axis of the transverse piezoelectric ceramic 4 is perpendicular to the axis of the vibration axis 9. The trimming block 6 is installed on the transverse piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com