Green body separator during aerated concrete producing process

A technology of aerated concrete and production process, which is applied in the field of building materials manufacturing, and can solve problems such as laborious, easy to break, and time-consuming manual separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

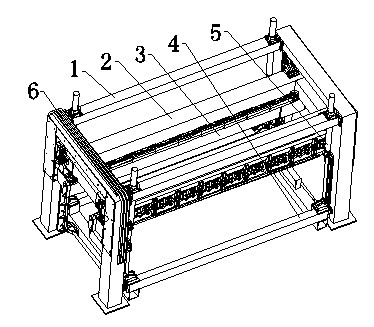

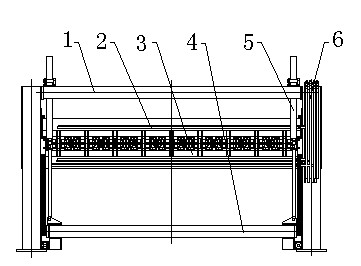

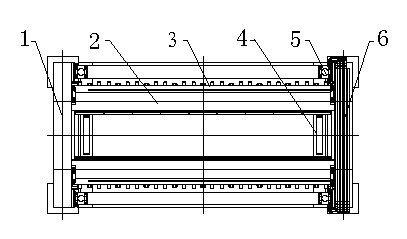

[0048] Such as Figure 1~38 As shown, a green body separation device in the production process of aerated concrete, the device is composed of a main frame 1, a mobile separation frame 2, a left and right clamping beam 3, a lifting frame 4, a lifting cylinder 5 and a hydraulic oil pipe 6 (see Figure 1~4 ), the main frame 1 is fixedly connected by the mast 1-1 and the connecting beam 1-2, the connecting beam 1-2 is fixed with the upper ear seat 1-5 of the lifting cylinder, and the mast 1-1 is fixed with the separation cylinder synchronization Racks 1-3 and lifting cylinder synchronous racks 1-4, hydraulic oil pipes 1-6 are installed on the mast 1-1 (see Figure 5~13 ), the mobile separation frame 2 consists of a frame 2-1, a first mobile synchronous part 2-2, a second mobile synchronous part 2-3, a clamping assembly 2-4, a guide sleeve fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com