Water supply tank with stirring function

A water supply tank and functional technology, applied in water supply devices, mixer accessories, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of long time for uniform mixing of disinfectant and tap water, slow diffusion of disinfectant, and affecting water use by users Safety and other issues, to achieve the effect of shortening the time of uniform mixing, good swing stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

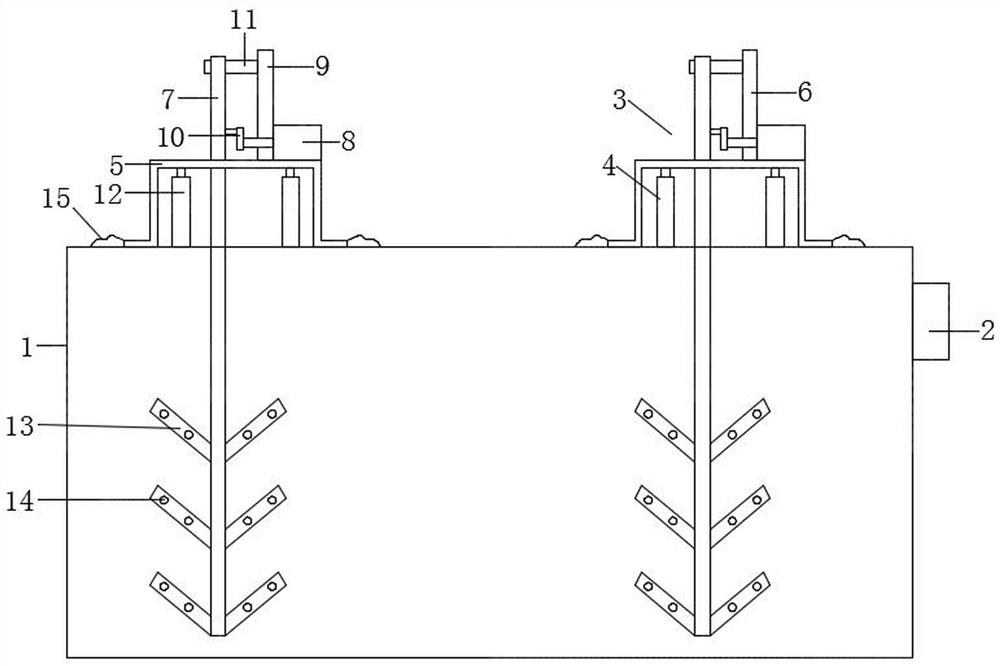

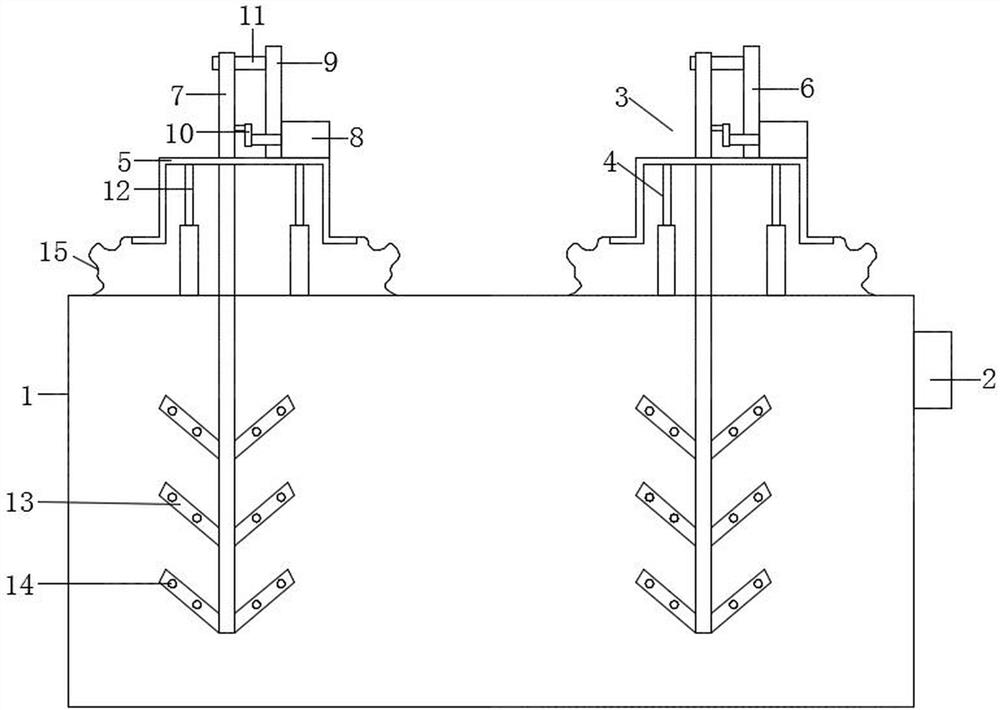

[0029] This embodiment discloses a water supply tank with stirring function. When the water tank is actually used, it can quickly and evenly mix the disinfectant and tap water by lifting and swinging, shortening the time for uniform mixing of the disinfectant and tap water, and effectively Ensure the user's water safety. Such as figure 1 , 2 As shown, it includes a box body 1, the box body 1 has a top cover and side walls, the top cover is provided with at least two sets of lifting swing devices 3 controlled by the control box 2, the number of the lift swing devices 3 Equipped according to the size of the water tank, for example, a water tank with a capacity of 20 tons can be equipped with two sets of lifting swing devices 3, and a water tank with a capacity of 50 tons can be equipped with three or four sets of lifting swing devices 3. The lifting swing device 3 includes a lifting mechanism 4, a casing 5, a swinging mechanism 6 and a swinging shaft 7, the lifting mechanism 4...

Embodiment 2

[0036] On the basis of Embodiment 1, this embodiment limits the control mode of each lifting swing device 3. Preferably, this embodiment limits the movement of the swing shaft 7 in each lift swing device 3 through the control box 2. The above-mentioned inconsistency in movement refers to inconsistency in lifting speed, inconsistency in lifting direction and / or inconsistency in swing amplitude. Specifically, different swing amplitudes, different lifting speeds, and delayed start instructions can be preset in the controller to realize the control of inconsistent actions. Take two sets of elevating swing devices 3 as an example, when the swing shaft 7 in one set of elevating swing devices 3 rises, the swing shaft 7 in the other set of elevating swing devices 3 just in time descends. The swing shaft 7 in one set of lifting swing device 3 swings to the side close to the box body 1, and the swing shaft 7 in the other set of lift swing device 3 just swings to the middle of the box bo...

Embodiment 3

[0038] On the basis of Embodiment 1 or Embodiment 2, this embodiment limits the swing angle of the swing shaft 7, and sets the swing angle of the swing shaft 7 to 20-60 degrees. Preferably, the swing angle of the swing shaft 7 The angle is 45 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com