High-precision heavy-duty surface rail compound matching lifting device

A lifting device, high-precision technology, applied in the direction of manufacturing tools, wood processing appliances, circular saws, etc., can solve problems such as limited contact surface, vibration of lifting shaft box, heavy load, etc., to achieve improved load capacity, stable up and down lifting, and craft require simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

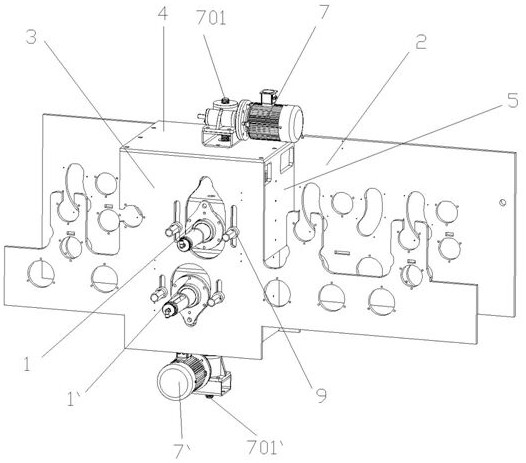

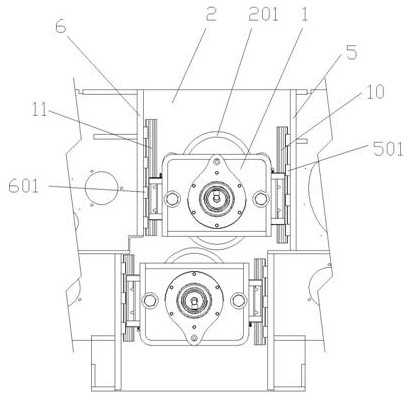

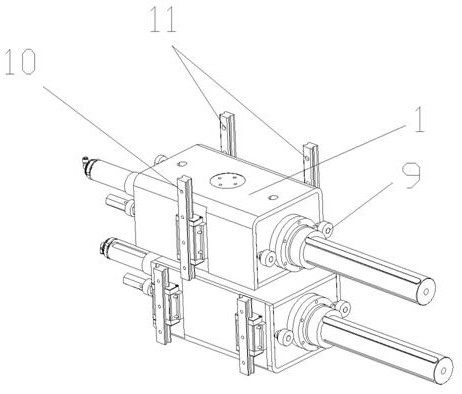

[0030] The high-precision heavy-load surface rail composite lifting device of the present invention includes an outer box and a lifting body. The cover plate 4, the front box plate 2, the rear box plate 3, the left box plate 5 and the right box plate 6 form a rectangular enclosure, and the top cover plate and the front box plate 2, the rear box plate 3, the left box plate 5 and the right box plate 6 Vertically fixed on the top surface, the lifting body includes an inner box body 1 and a top drive device 7, the inner surface of the front box plate 2 has a raised front high-precision convex surface 201, and the front high-precision convex surface 201 is vertical to the front end surface of the inner box body 1 It also includes a left slider rail 10 and a right slider rail 11. The left and right sides of the inner box 1 are connected to the left box plate 5 and the left box plate 5 through the left slider rail 10 and the right slider rail 11 respectively. The right box plate 6 is...

Embodiment 2

[0035] On the basis of Embodiment 1, there are two groups of lifting bodies, one is located above and the other is located below. The two sets of lifting bodies are equipped with main shafts, and the main shaft axes of the lower lifting body and the upper lifting body main shaft are vertically staggered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com