Single screw extruder on basis of double screw edge push conveying

A single-screw extruder and double-foil technology, applied in the field of high-output extrusion molding, can solve the problems of high energy consumption, poor adaptability to different processing materials, and low conveying efficiency of the single-screw extruder, and achieve high product quality. , The effect of small pressure fluctuation and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

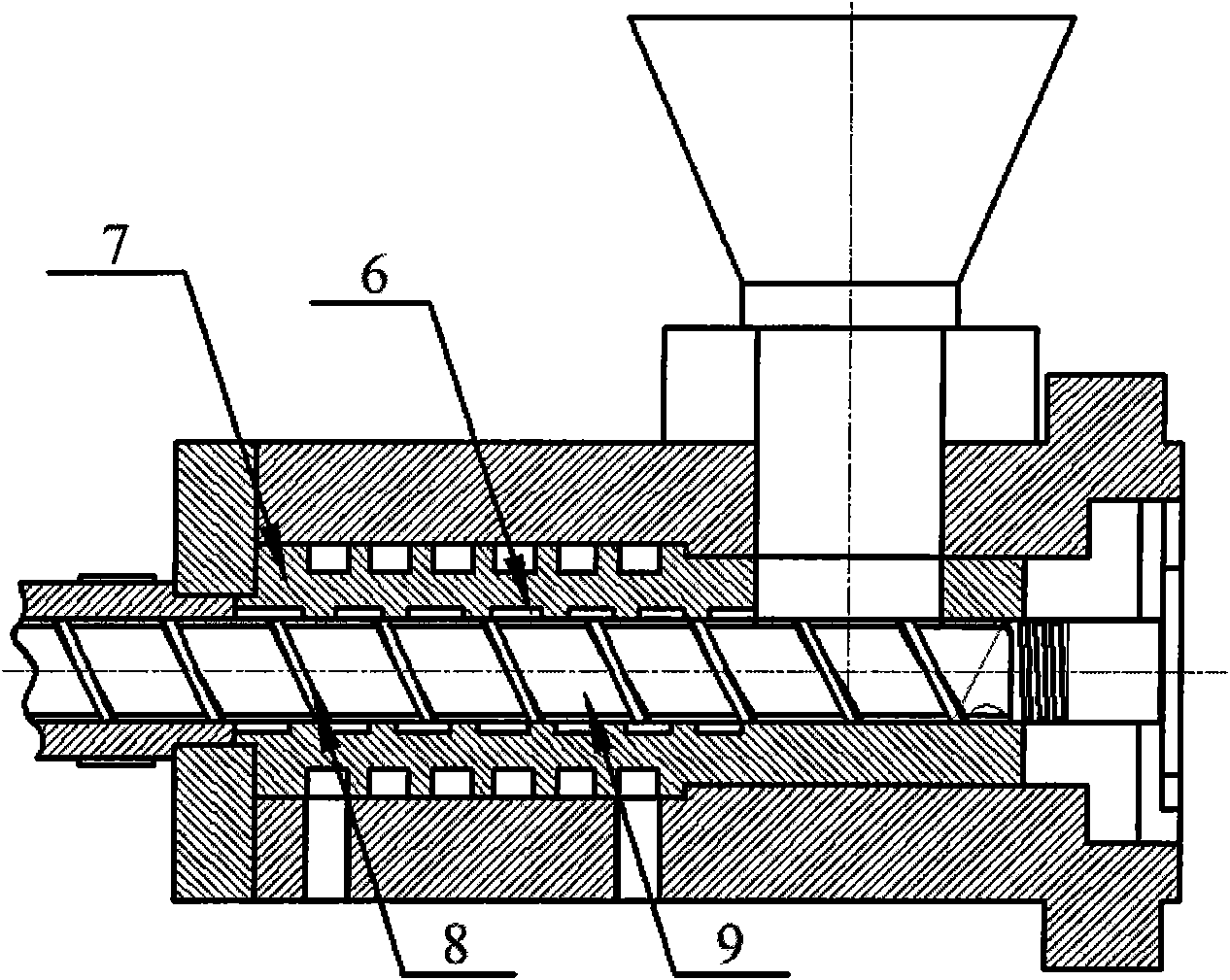

[0021] The first embodiment: the processing raw material of this example is high-density polyethylene (brand: 5000S), screw rod diameter 90mm, length-to-diameter ratio 30, thread head number 1, right-handed, feeding section screw groove deep 10mm, screw speed 125r / min, The driving power is 167KW, the barrel bushing groove is left-handed, the helix angle is 50°, the number of grooves is 12, the groove depth is 8mm, and the groove width is 16mm.

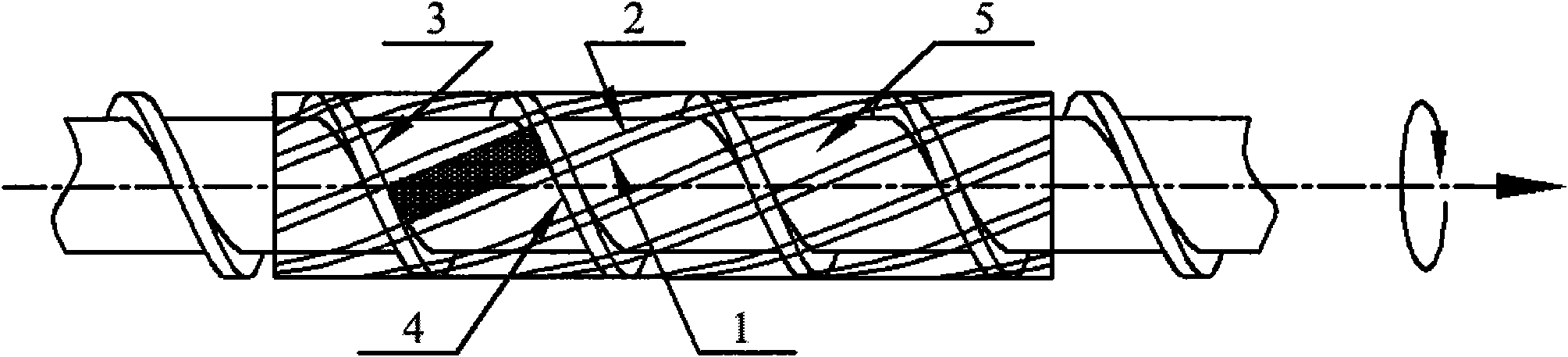

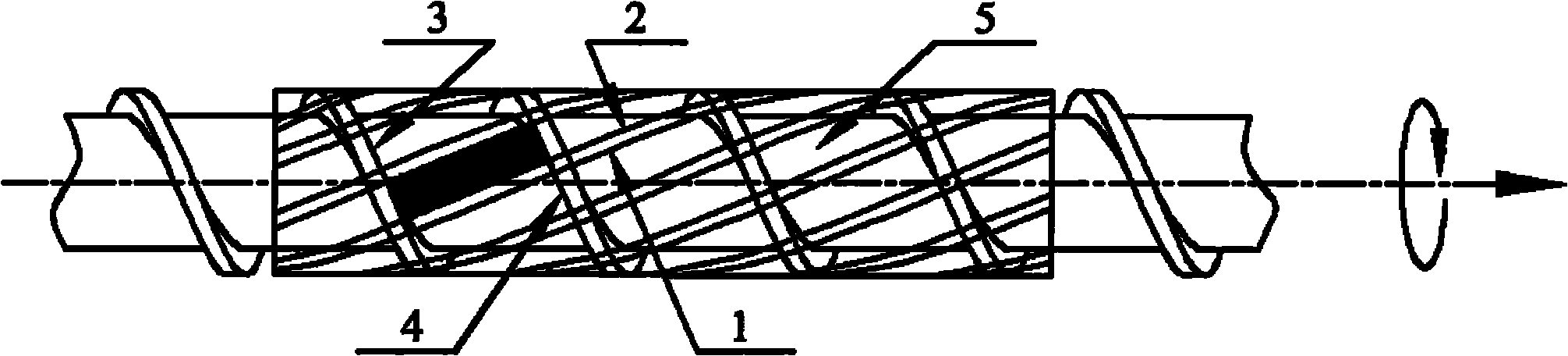

[0022] The working principle of material conveying of the present invention is as seen figure 2 , The semi-closed storage chamber 5 is surrounded by the groove flight propelling surface 1, the groove flight trailing edge surface 2, the screw flight propelling surface 3 and the screw flight trailing edge surface 4. The top view of the material storage chamber 5 is a parallelogram, and the top angle of the parallelogram is the angle between the barrel liner groove 6 and the screw screw groove 9 . The height of the storage chamber 5 is ...

no. 2 example

[0024] The second embodiment: the processing raw material of this example is low-density polyethylene (brand: LD607), screw rod diameter 45mm, aspect ratio 26, thread head number 2, right-handed, feeding section spiral groove depth 4mm, screw speed 120r / min, The driving power is 17KW, the barrel bushing groove is left-handed, the helix angle is 55°, the number of grooves is 8, the groove depth is 5mm, and the groove width is 9mm.

[0025] The working principle of material conveying of the present invention is as seen figure 2 , The semi-closed storage chamber 5 is surrounded by the groove flight propelling surface 1, the groove flight trailing edge surface 2, the screw flight propelling surface 3 and the screw flight trailing edge surface 4. The top view of the material storage chamber 5 is a parallelogram, and the top angle of the parallelogram is the angle between the barrel liner groove 6 and the screw screw groove 9 . The height of the storage chamber 5 is equal to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com