Device and method for testing ink box chip of printer

An ink cartridge chip and testing device technology, applied to printing devices, printing, etc., can solve the problems of cumbersome work, large losses, and cumbersome testing process for operators, and achieve the effect of high degree of operation automation, high degree of automation, and high testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of printer cartridge chip testing device

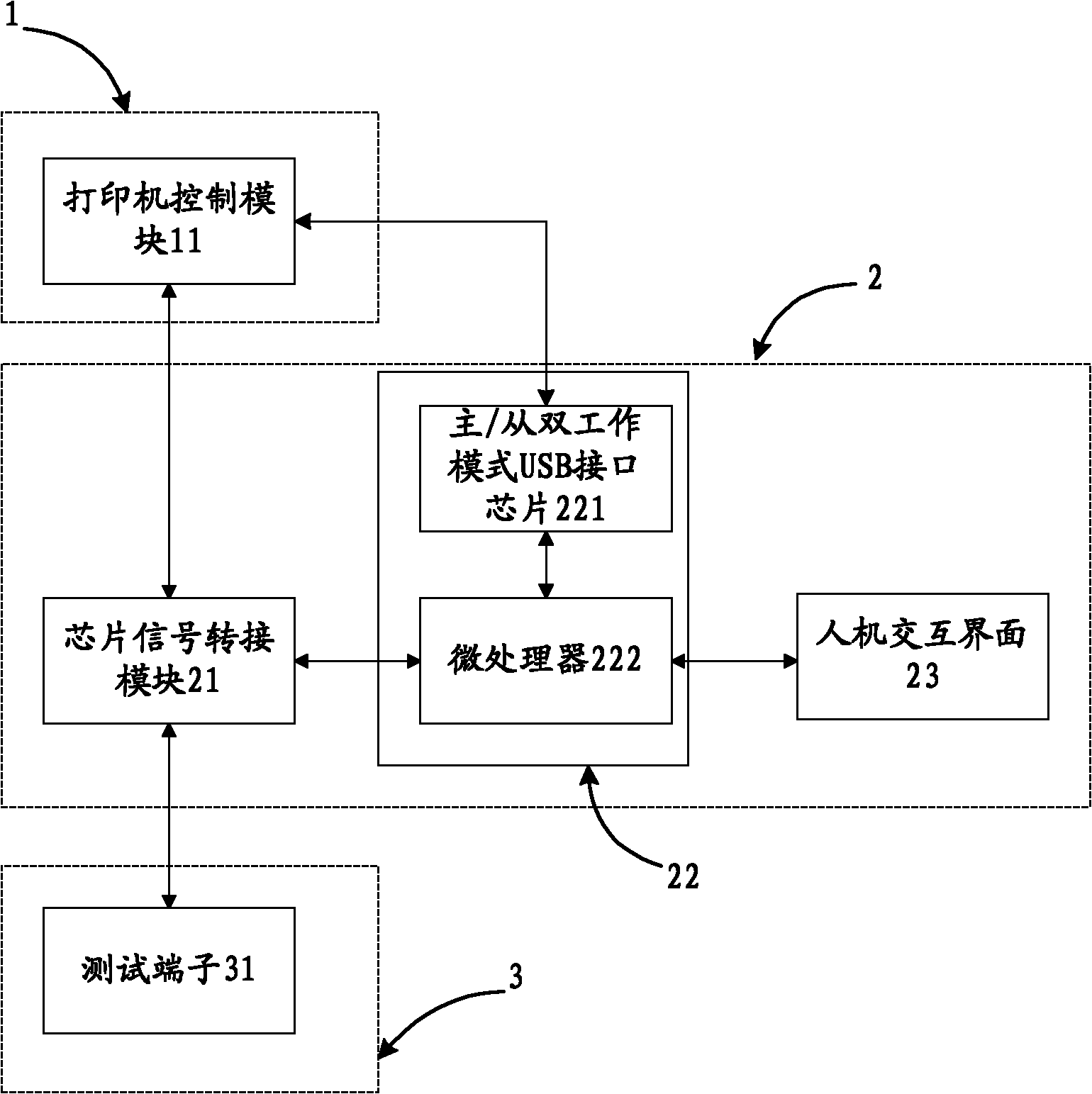

[0027] see figure 2 , the printer ink cartridge chip testing device is composed of an inkjet printer 1 , a test control box 2 and a test frame 3 .

[0028]The inkjet printer 1 has a printer control module 11 inside. Wherein, there is a chip signal adapter board provided with a chip signal adapter module in the word cart of the inkjet printer 1, and the chip signal adapter board is moved from the word cart of the inkjet printer 1 to be fixed in the test control box 2 Install. The chip signal conversion module 21 located in the test control box is electrically connected with the printer control module located in the inkjet printer through a cable.

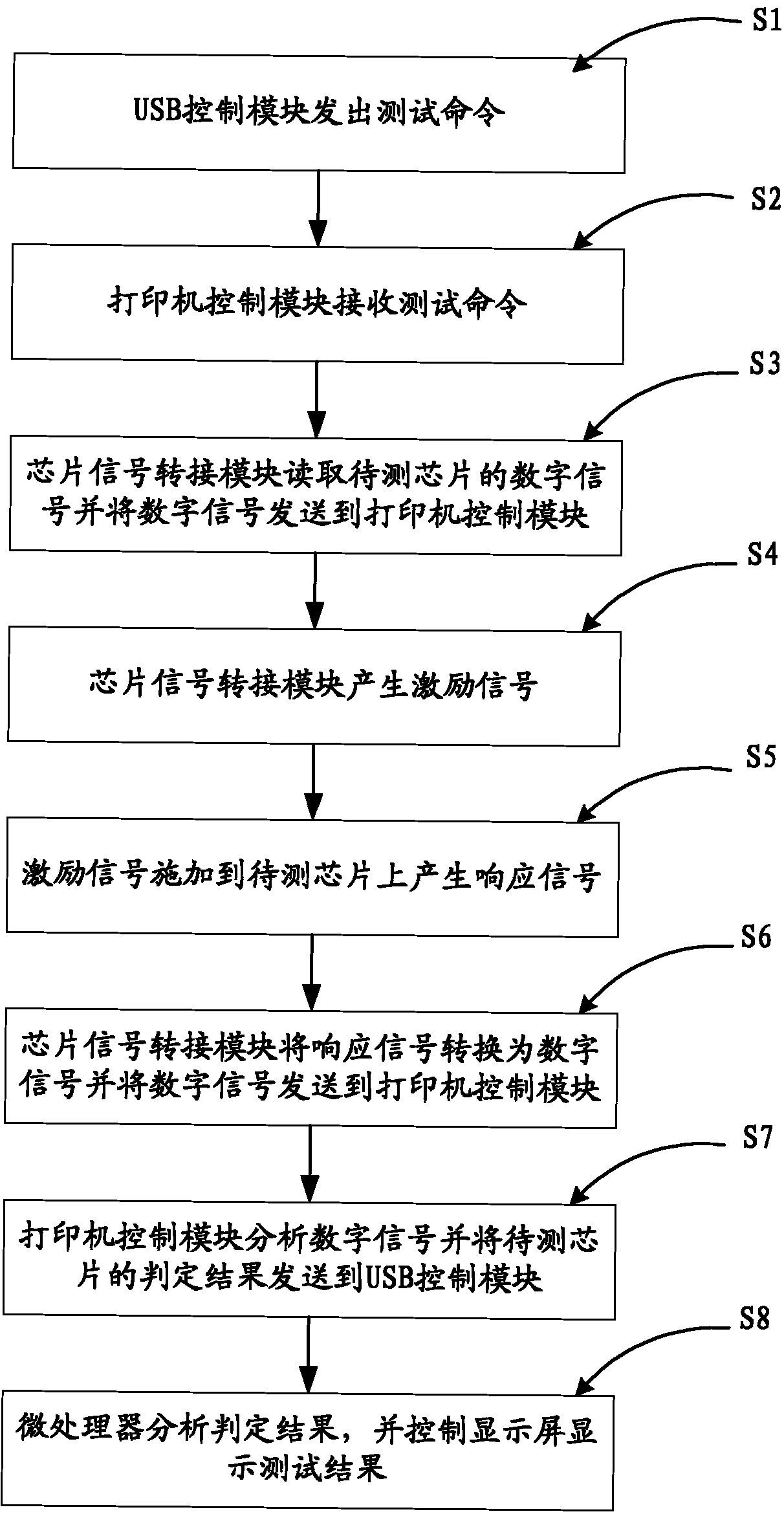

[0029] The test control box is provided with a USB control module 22 for controlling the printer test process and obtaining chip test results. Connected microprocessor 222 . The host / slave dual working mode USB interface chip 221 is electrically connected to the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com