Fermentation and air distribution device for aerobic composting of organic solid waste

An organic solid and aerobic composting technology, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of pipeline blockage, reduced treatment effect, uneven air distribution, etc., to reduce energy consumption and production costs , shorten the fermentation cycle, and meet the effect of aerobic demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

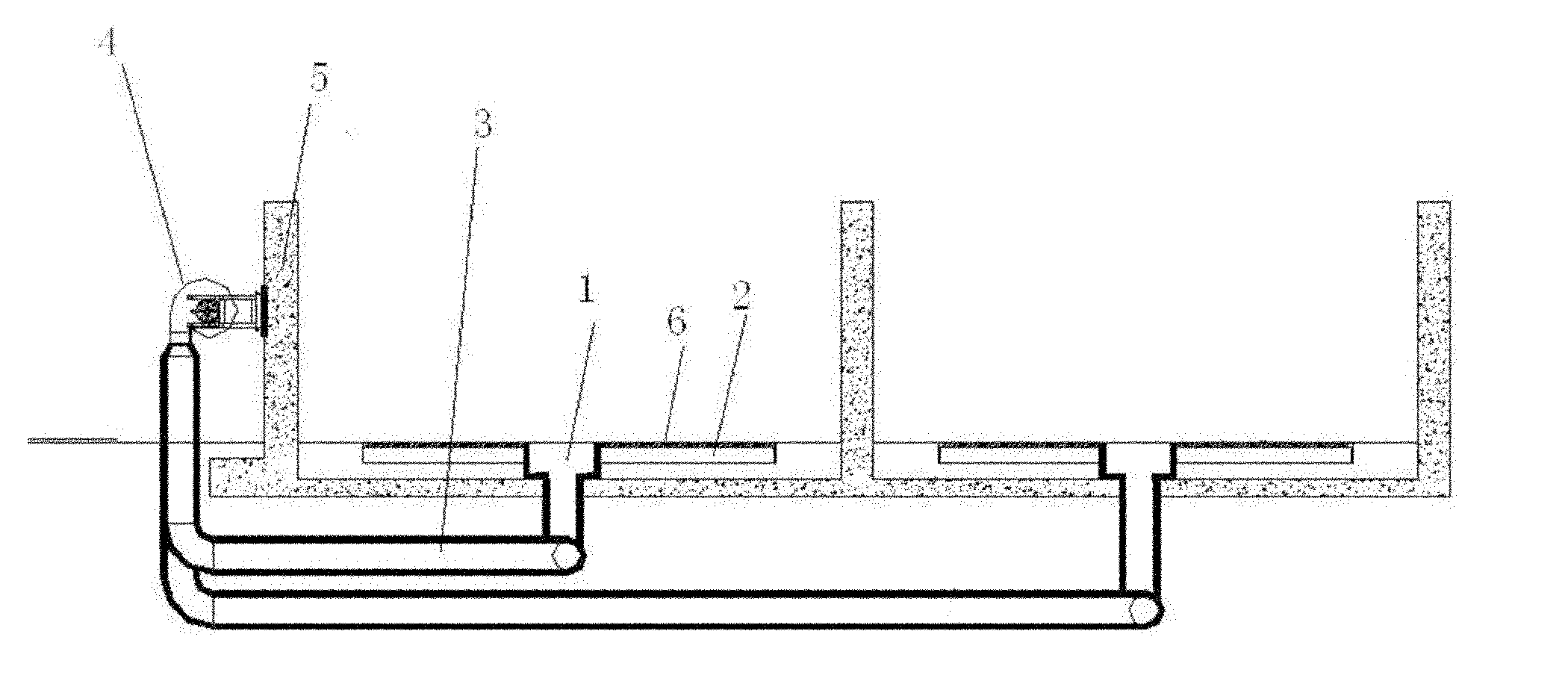

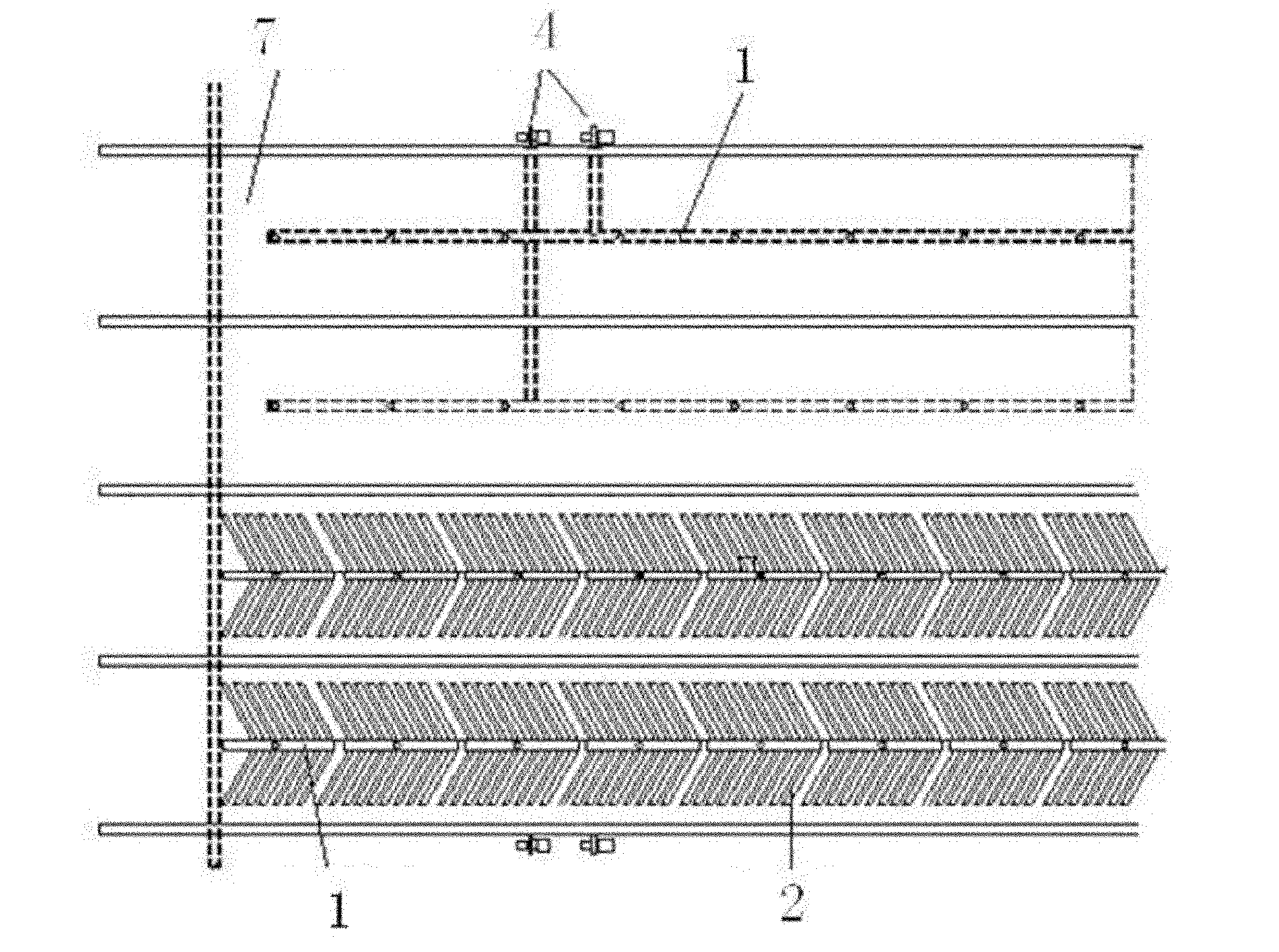

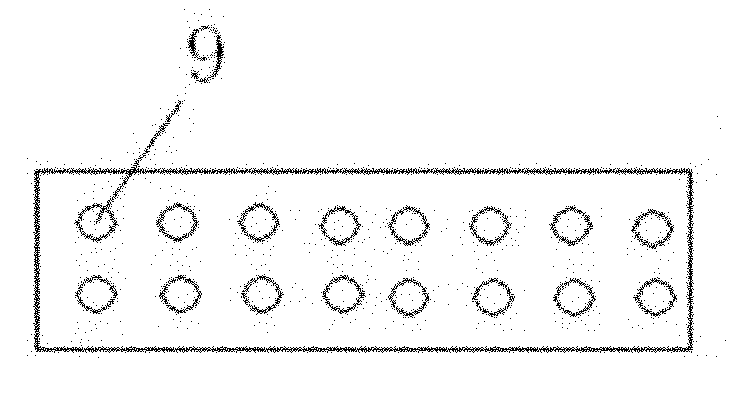

[0017] see figure 1 , figure 2 , a fermentation gas distribution device for aerobic composting of organic solid waste, which is provided with an automatic control system 4, and also includes a main gas distribution tank 1 arranged in the middle of the fermentation tank 7 and parallel to the wall of the fermentation tank and uniformly distributed on the main gas distribution tank. Two rows of branch air distribution grooves 2 on both sides of the groove 1 and communicated with the main air distribution groove 1; see image 3 , The main air distribution groove 1 and the distribution air groove 2 are respectively provided with a cover plate 6 with a plurality of ventilation holes. A row of fermentation tanks 7 can be set in the specific implementation, and a set of gas distribution device according to the present invention is arranged in each fermentation tank 7, and the mark 5 in the figure is the tank wall of the fermentation tank 7.

[0018] see Figure 4 , the automated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com