Construction machine for replacing ballasts of rail

A technology for construction machinery and ballast, which is applied in the direction of tracks, ballast layers, roads, etc., and can solve the problems of high cost and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

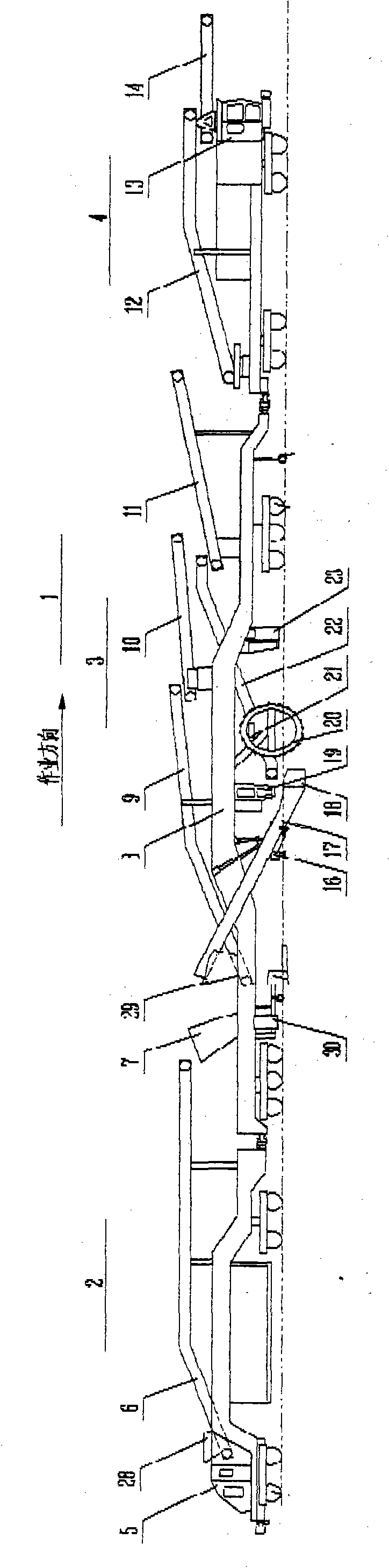

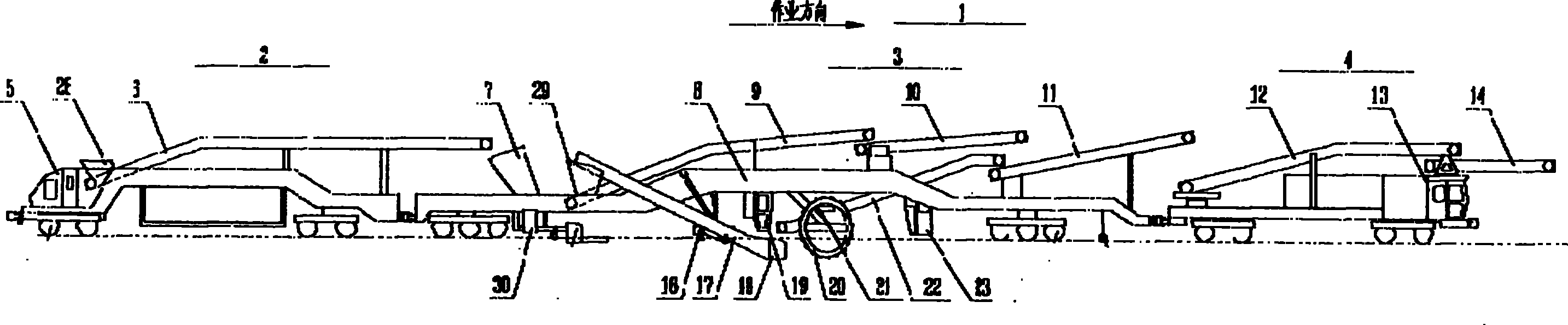

[0014] As shown in the accompanying drawings, the construction machine (1) for excavating track ballast of the present invention is made up of a power car (2), a work vehicle (3), and a ballast throwing car (4). The operating vehicle (3) includes a frame (8) that utilizes a rail mechanism to walk on the track. The frame (8) has the characteristics of low middle protrusions at both ends, and the middle protrusions allow space to place relevant operating mechanisms. The guide groove ( 17) Placed obliquely on the frame, the upper end is supported on the left upper part of the frame (8), and the lower end is located in the middle of the frame (8). During operation, it can be moved along the working direction with the frame (8). Full-section circular ballast excavation The rake chain (18) is assembled in the guide groove (17), and an adjustment device that can change the height of the excavation rake chain (18) and the position perpendicular to the direction of the track is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com