Steel structure open web combined dam

A steel structure and composite dam technology, applied in dams, pier dams, etc., can solve problems such as temperature cracks in the face plate, penetration and stability of the overall structure, inconvenient maintenance and repair, etc., to shorten the construction period, facilitate maintenance, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

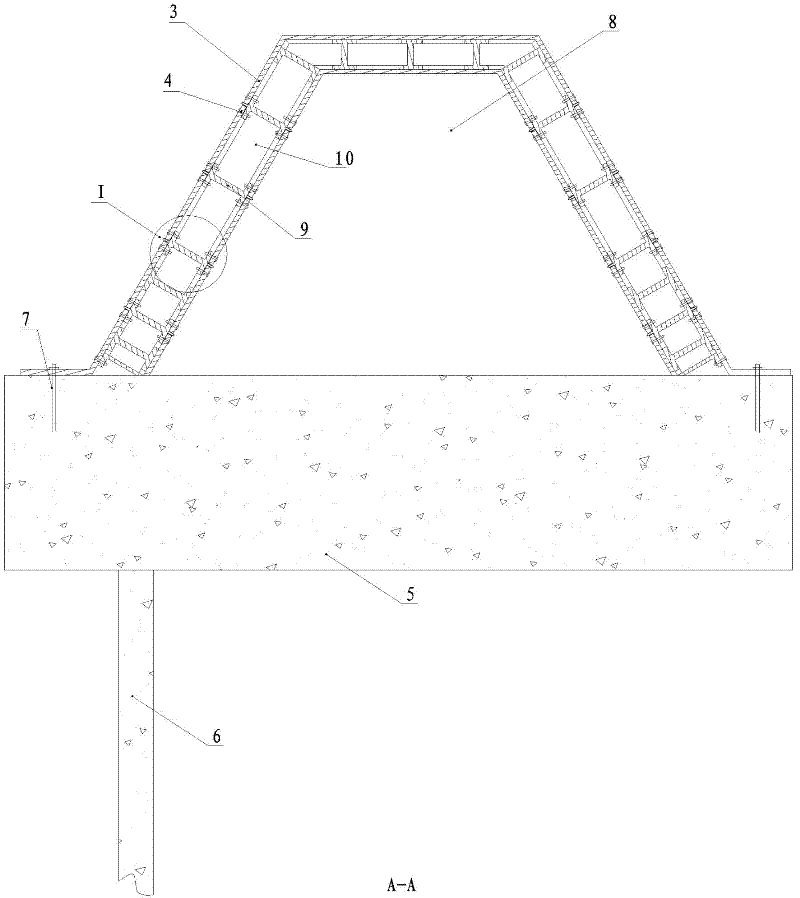

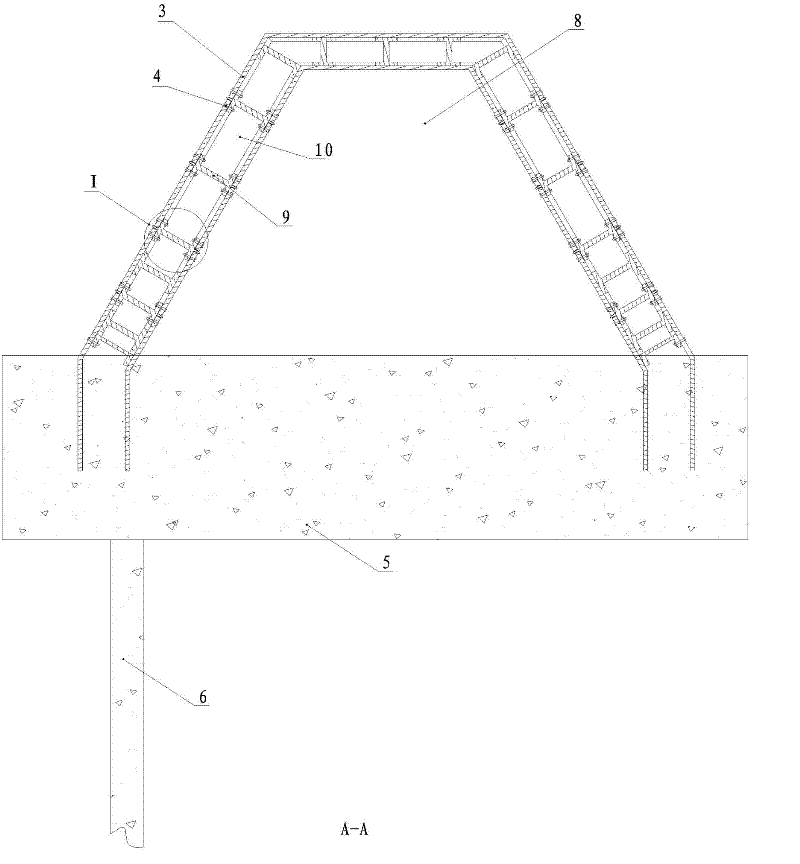

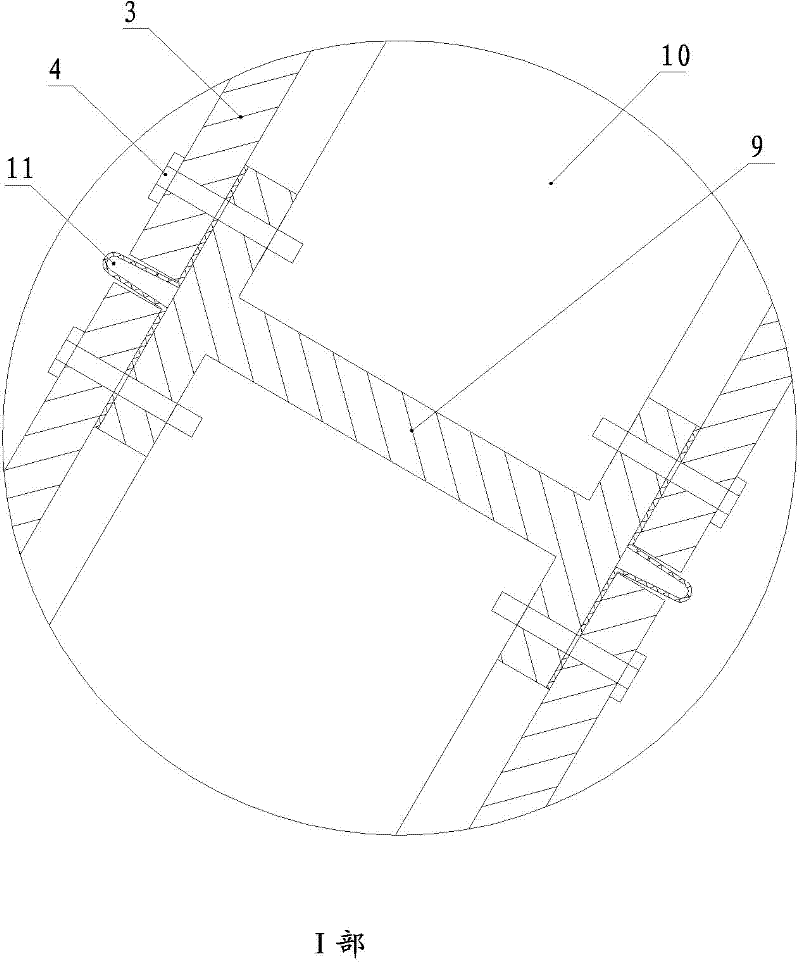

[0035] Embodiment one: see figure 1 , figure 2 , Figure 4 , Figure 6-Figure 8 , a steel structure hollow composite dam in the figure, which contains a certain number of concrete buttresses, concrete caps below the buttresses, and steel structure composite panels above the buttresses, and a cut-off wall is arranged under the concrete caps, said The cross-section of the steel structure composite panel matches the cross-section of the pier, and is covered on the top and both sides of the pier; the steel structure composite panel contains an internal skeleton and several unit steel plates covering the two surfaces of the skeleton. The splicing gap between the unit steel plates is located at the frame, the edges of the unit steel plates are connected to the frame by fasteners, and the joints between adjacent unit steel plates are provided with sealing structures.

[0036] The skeleton includes vertical beams and cross beams that intersect vertically and horizontally. Both the...

Embodiment 2

[0040] Embodiment two: see figure 1 , image 3 , Figure 4 , Figure 6-Figure 8 , embodiment two is basically the same as embodiment one, and the similarities will not be repeated. The difference is that the lower edge of the steel structure composite panel is embedded in a section of the river bed plinth (such as figure 2 shown in ), and is provided with a sealing structure; the edge of the steel structure composite panel at both ends of the dam body is embedded in a section of the toe plate of the river channel, and is provided with a sealing structure.

Embodiment 3

[0041] Embodiment three: see figure 1 , figure 2 , Figure 5 , Figure 6-Figure 8 , Embodiment 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the sealing structure includes a cross-section approximately "Ω"-shaped sealing strip, and the two lower edges of the lower part of the sealing strip are respectively press-fitted. It is between the unit steel plate and the surface of the frame, and is fixed by the fastener; the upper part of the sealing strip is a cap structure, and the cap structure covers the joints of the adjacent unit steel plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com