Method and device for lapping section steel reinforced concrete beam with section steel columns

A technology of concrete beams and lap joints, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of steel column strength damage and affect the quality of construction, so as to achieve complete grouting, avoid blocking, and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

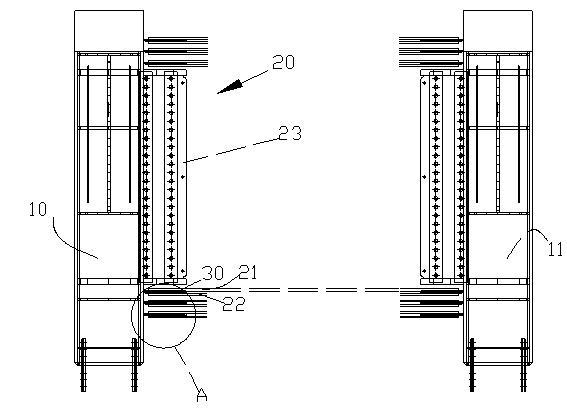

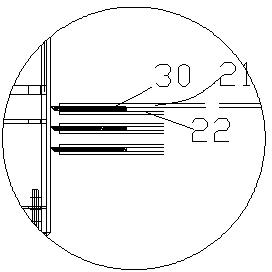

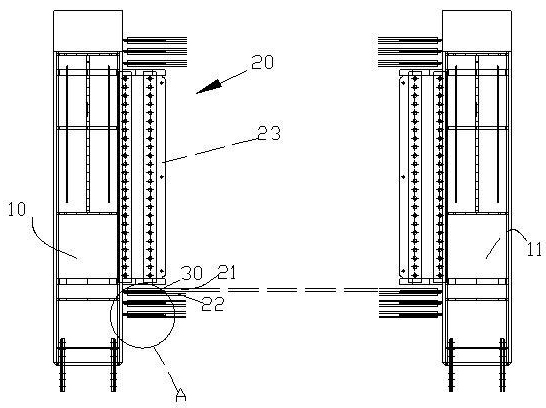

[0017] figure 1 Shown is a schematic diagram of the overlapping installation of a steel concrete beam and a steel column; wherein the steel concrete beam 20 is installed between the steel columns 10 on both sides, and the steel concrete beam 20 includes an internal steel 23 and longitudinal steel bars arranged around the internal steel 23 ( because figure 1 It is a schematic cross-sectional view, so only the reinforcing bars on the upper and lower sides of the internal shaped steel 23 can be seen). During construction, firstly connect sections of longitudinal steel bars correspondingly to the shaped steel columns; then measure the port straight thread spacing of the longitudinal steel bars correspondingly fixed on both sides of the shaped steel columns, and then cut the longitudinal steel bars; finally carry out Concrete cast steel concrete columns. Wherein, any appropriate method in the prior art may be used for cutting steel bars, which will not be repeated here.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com