Lever system for pumping unit

A technology of pumping units and levers, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. It can solve the problems of small output power of power output components, relatively high power output requirements, and large energy consumption of pumping units. , to achieve the effect of reducing power output requirements, reducing energy consumption, and reducing driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

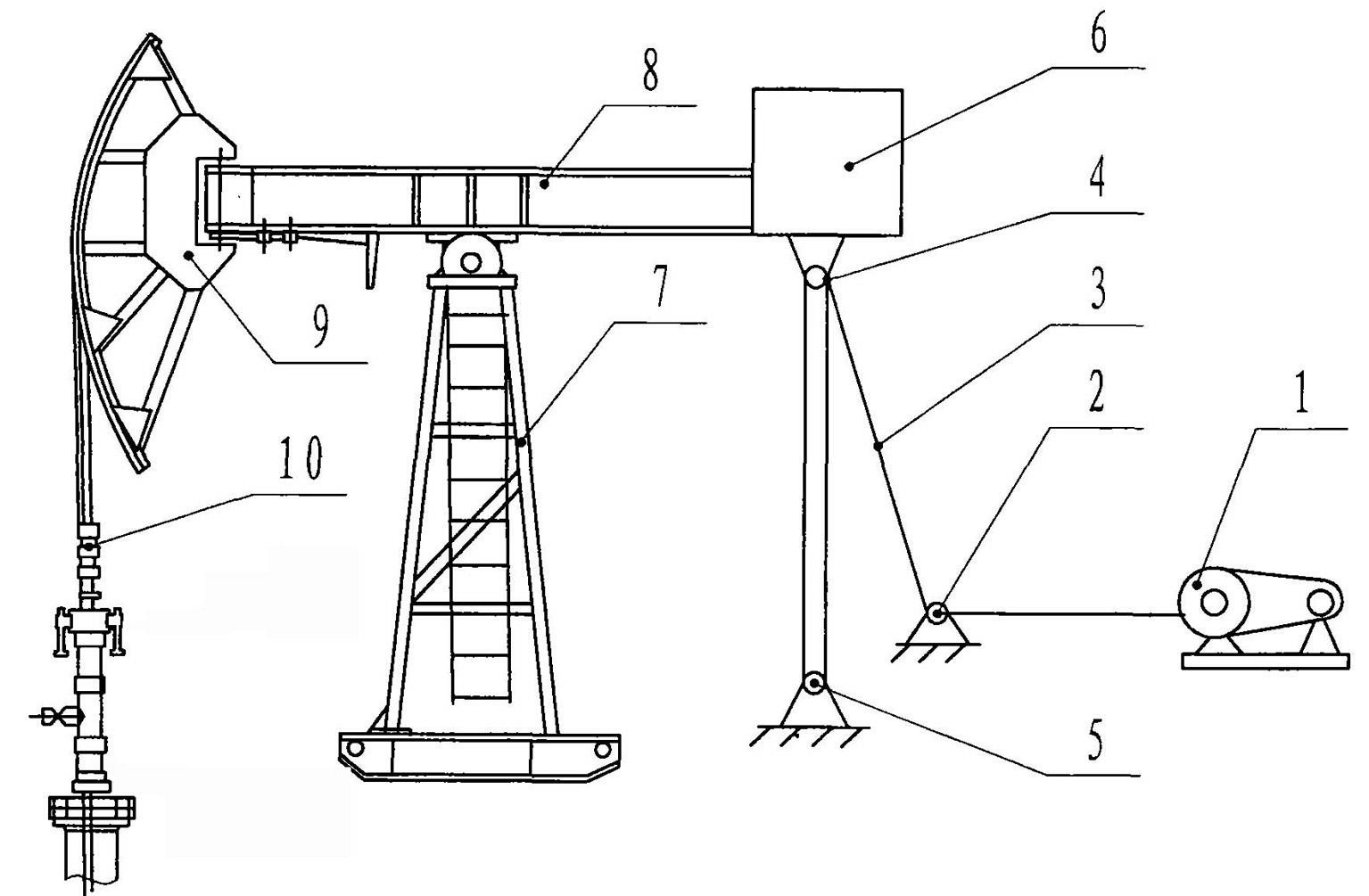

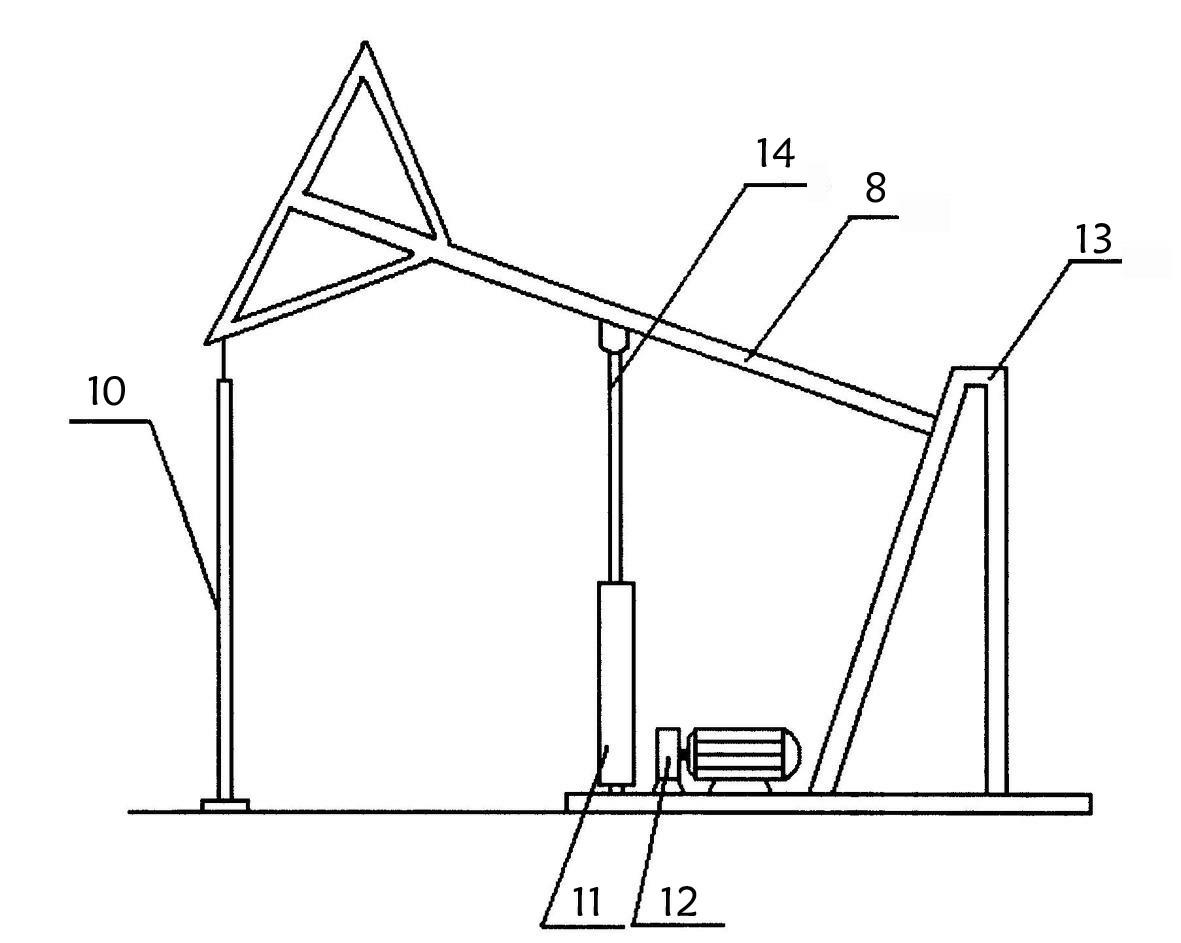

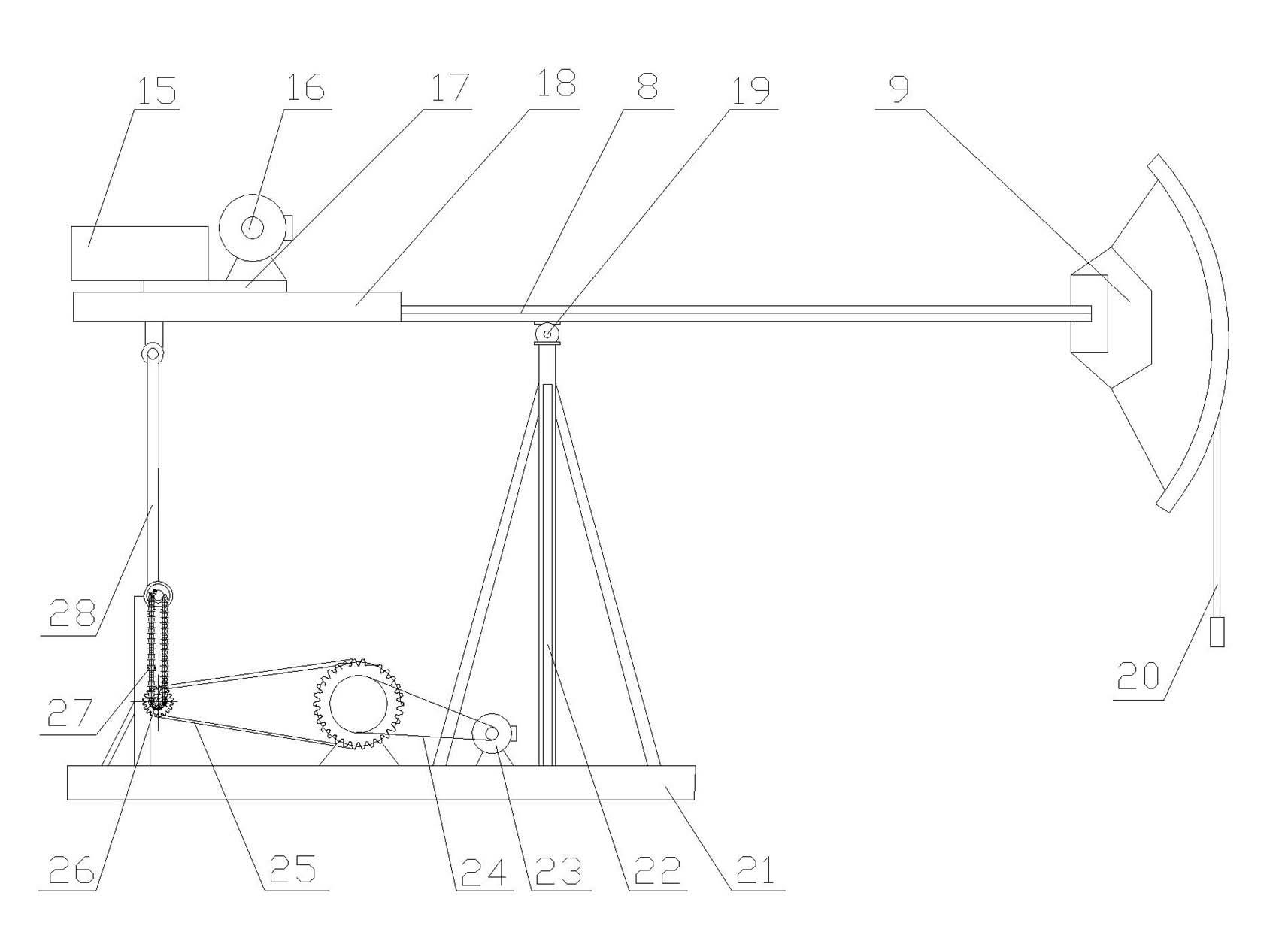

[0035] According to the present invention, with reference to the attached image 3 , which shows a pumping unit lever system comprising:

[0036] The main support 22 can be equivalent to the attached figure 2 The bracket shown in is mainly used as a fixed hinge support, that is, a mounting bracket for the hinge support;

[0037] The traveling beam 8, the middle part is installed on the top of the main bracket 22 through a hinge, forming a basic lever mechanism;

[0038] The donkey head 9 is arranged at one end of the beam, which is on the side of the sucker rod, connected to the sucker rod through the rope hanger 20, and the sucker rod is installed on the oil outlet tee at the wellhead through the wellhead packing seat;

[0039] It also includes:

[0040] Pull rod 28, the upper end of the pull rod is hinged to the other end of the beam. Of course, the pull rod also has the function of pushing. When the head of the donkey goes down, it needs to be driven by the pull rod. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com