Plug-in type high-pressure plate valve

A flat valve, plug-in technology, applied in sliding valves, valve devices, engine components, etc., can solve the problems of troublesome, labor-intensive, and time-consuming maintenance methods, and achieve the effect of long maintenance-free period and convenient and fast maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

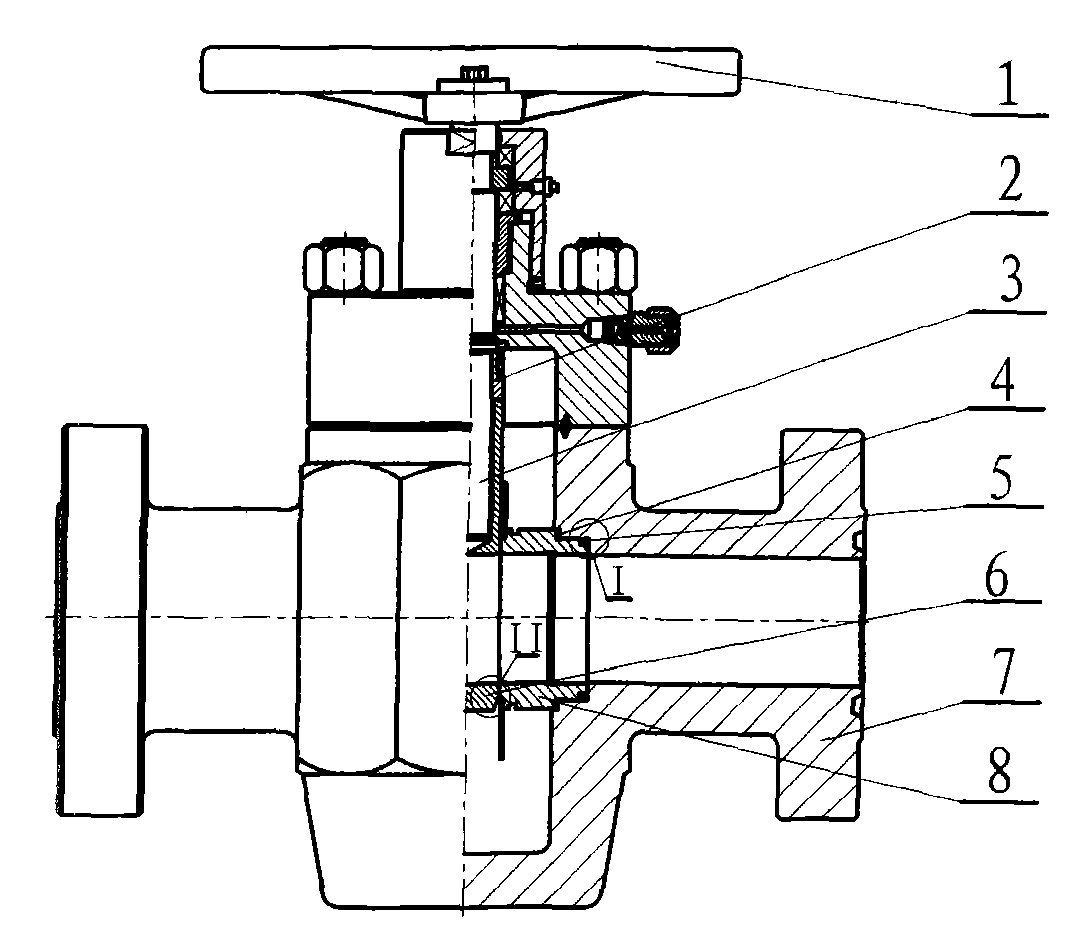

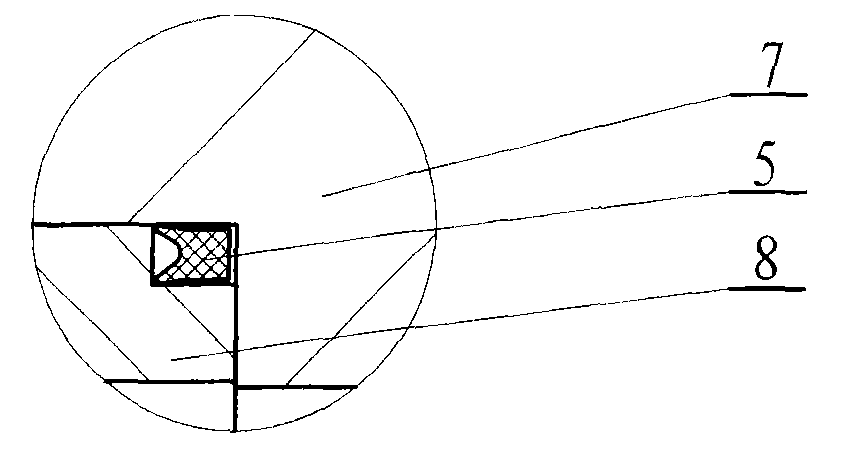

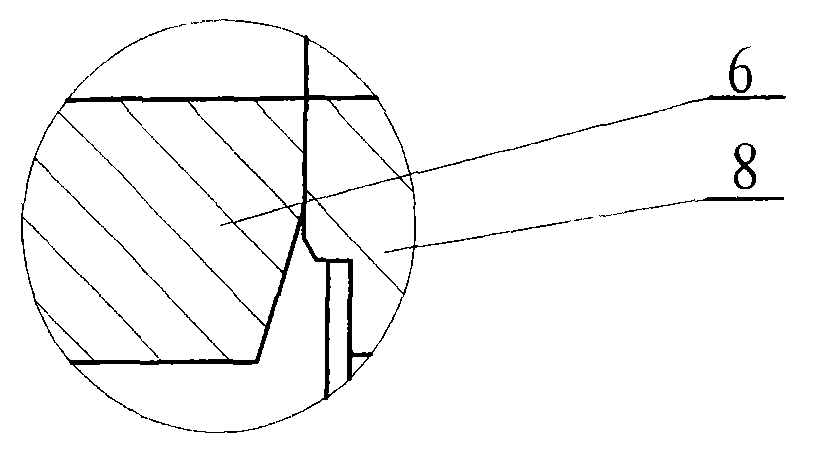

[0010] as attached figure 1 , 2 As shown, two wave springs 4 are arranged on the contact surface between the valve body 7 and the valve seat 8 and the orientation of the two wave springs 4 is that the openings face each other. as attached figure 1 , 3 As shown, the lower ends of the planes on both sides of the gate 6 are designed as symmetrical slopes.

[0011] When the present invention is working, turning the hand wheel 1 clockwise drives the valve stem 3 to make the valve stem nut 2 move downward in a straight line along the axis of the valve stem 3, and the valve stem nut 2 presses the gate plate 6 to move downward, so that the valve stem 6 moves downward. The solid planes on both sides are engaged with the sealing surfaces of the left and right valve seats 8 under the lateral elastic force of the left and right wave springs 4 to achieve closure. Since the left and right valve seats 8 and the valve body 7 are in a gap floating fit and are provided with two lip-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com