Method for blasting pile well five-eye conical cut and structure

A technology of conical cutting and pile wells, which is applied in blasting and other directions, can solve problems such as low efficiency, reliability affecting construction safety, and high labor intensity, and achieve the effects of ensuring safety and health, good blasting loosening quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

[0020] Example.

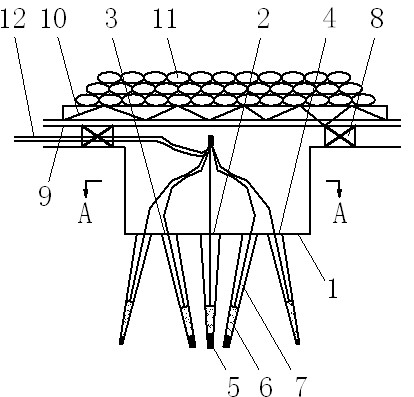

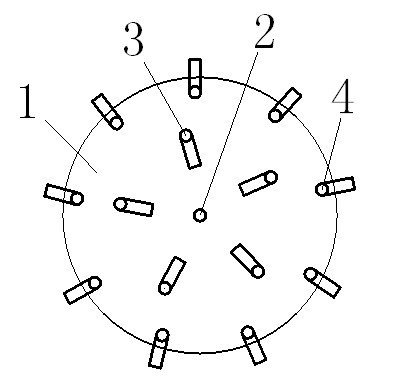

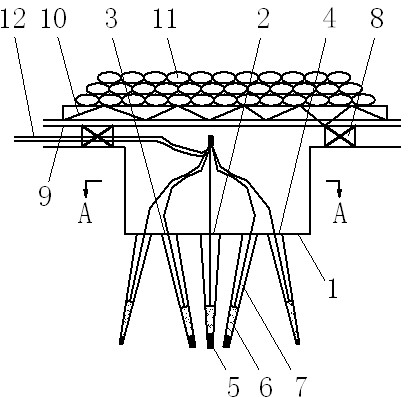

[0021] The present invention as figure 1 shown. A five-hole conical cutting blasting method for a pile shaft, the method is to blast on the rock at the bottom of the column hole 1, and the operation steps are as follows:

[0022] A. First, punch a vertical center hole 2 in the center of the rock at the bottom of the column hole 1, and punch five cut holes 3 evenly distributed along the circumference around the center hole. The quantity of 4 is 1.8~2 times of the quantity of cut hole 3;

[0023] B. Place the detonator 5 at the bottom of the central hole 2, the cutout hole 3 and the peripheral hole 4, and leave the lead wire 12 of the detonator 5 out of the hole; fill the explosive 6 above the detonator 5, and fill the drilled hole above the explosive 6. rock powder 7;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com