System calibration method of tire balancing machine

A tire balancing and system calibration technology, applied in static/dynamic balance testing, machine/structural component testing, and measuring devices, etc., can solve problems such as affecting measurement results, system calibration errors, and inability to guarantee absolute phase of measured rotational speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

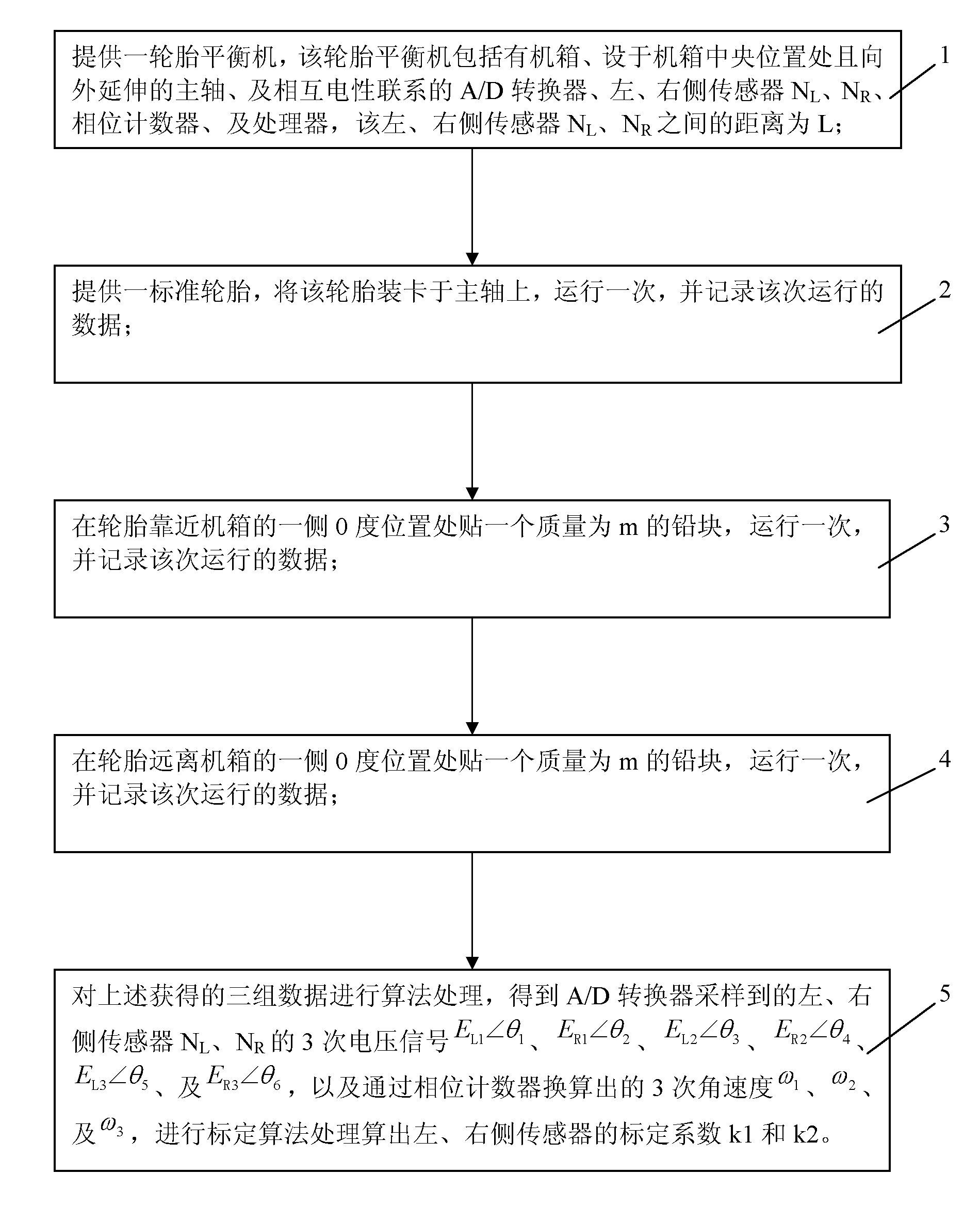

[0044] like figure 1 , 2 As shown, the present invention provides a system calibration method for a tire balancing machine, which includes:

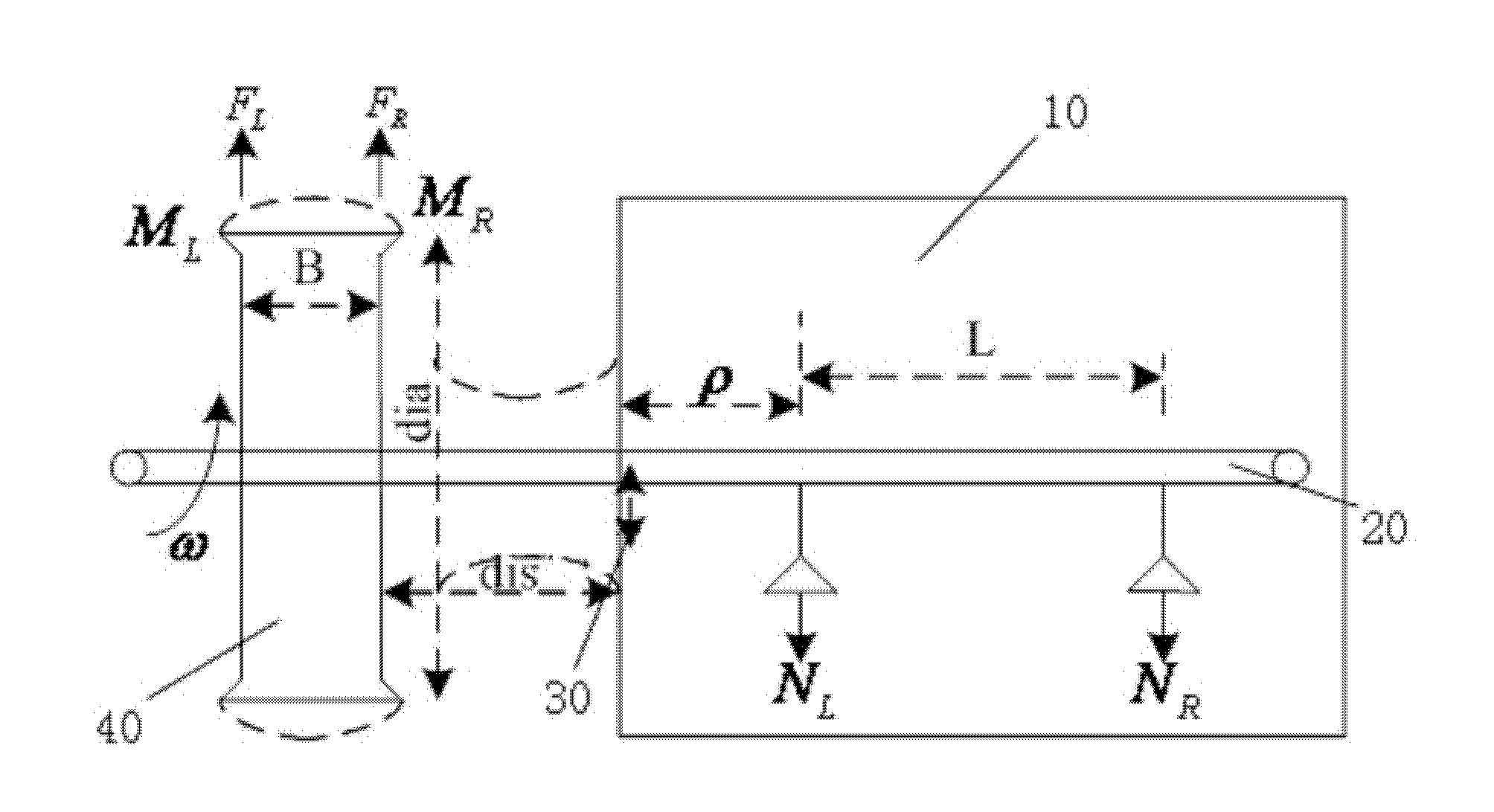

[0045] Step 1, providing a tire balancing machine, which includes a chassis 10, a main shaft 20 located at the center of the chassis 10 and extending outwards, an A / D converter electrically connected to each other, left and right sensors N L , N R , phase counter 30, and processor (not shown), the left and right side sensors N L , N R The distance between them is L.

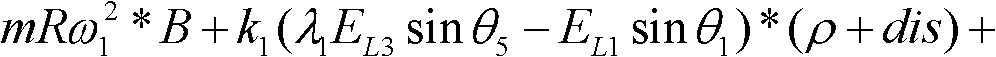

[0046] Step 2, provide a standard tire 40, clamp the tire 40 on the main shaft 20, run once, and record the data of this run. The tire 40 is mounted on the main shaft 20 and rotates, generating an induction force at the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com