Inner zoom lens

A zoom lens and focal length technology, applied in the field of internal zoom lenses, can solve the problems of total optical length, increased manufacturing cost, large aperture, etc., and achieve the effects of short overall optical length, low manufacturing cost, and good imaging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

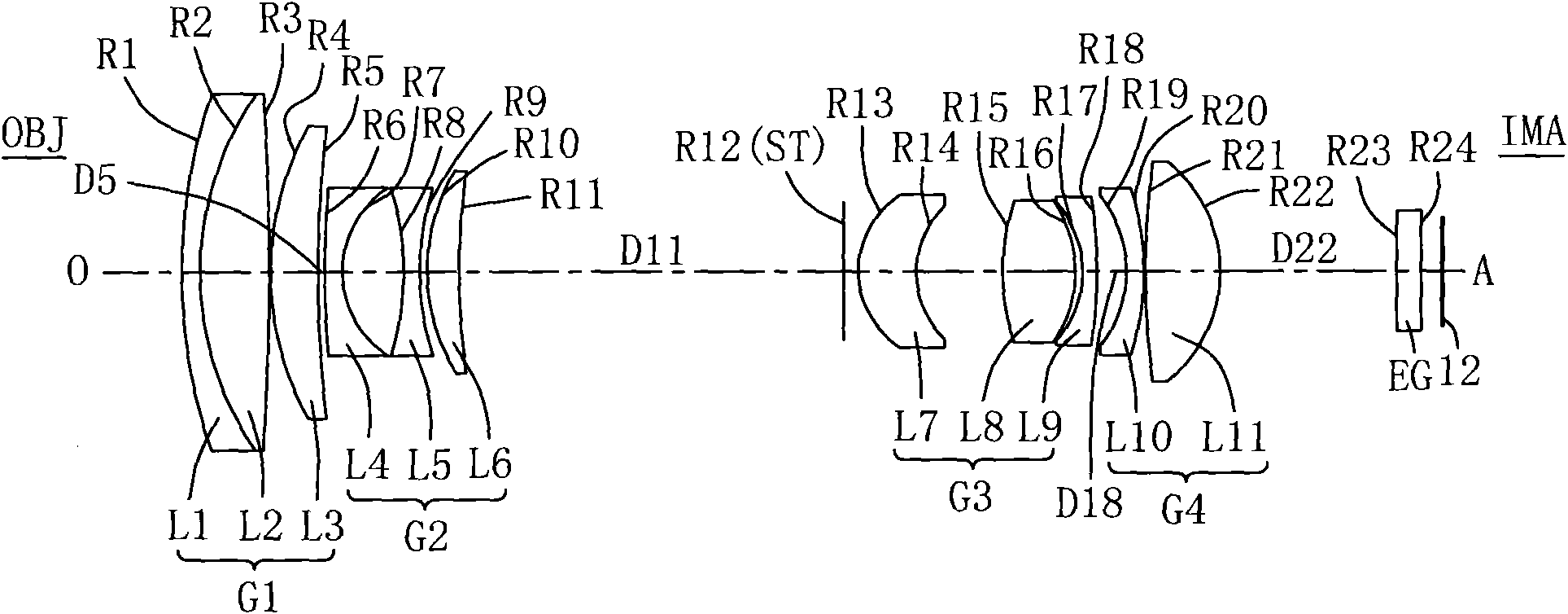

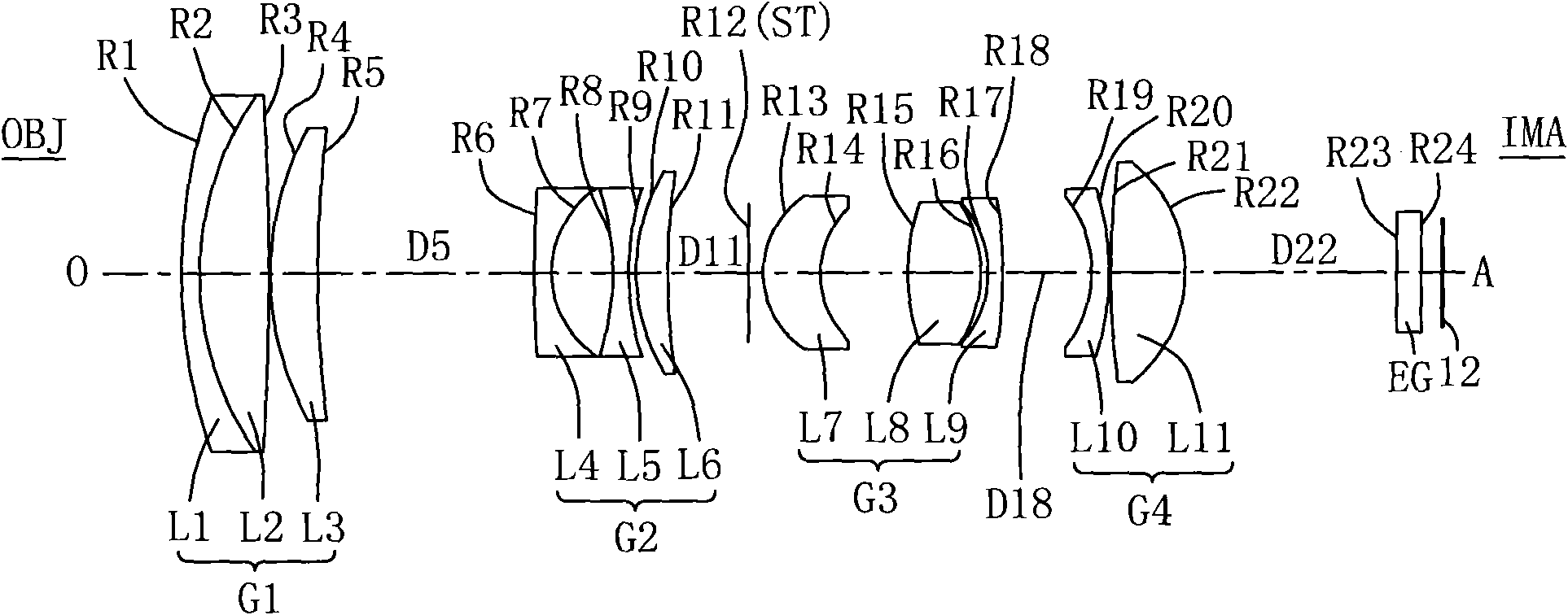

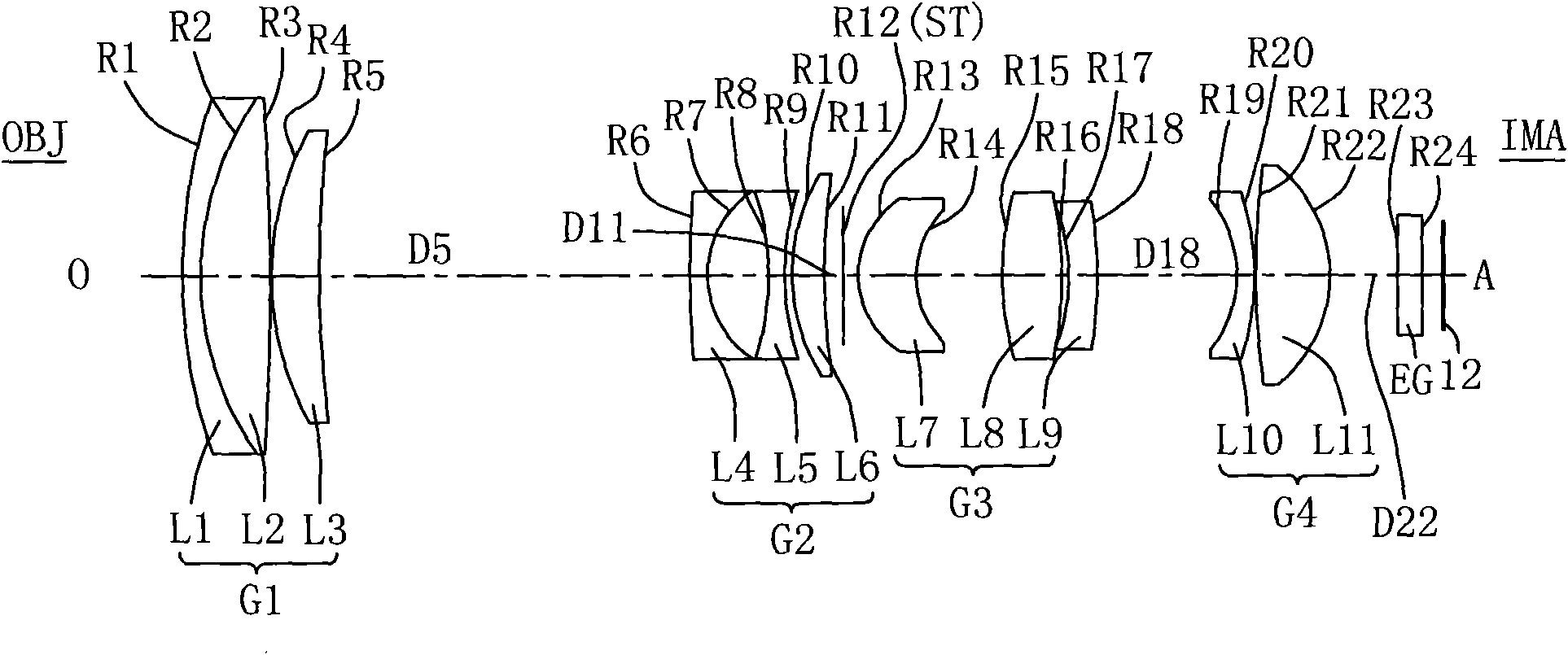

[0047] Please also refer to Figure 1 to Figure 3 , Figure 4A to Figure 4D , Figure 5A to Figure 5D and Figure 6A to Figure 6D . in, Figure 1 to Figure 3 Respectively show schematic diagrams of the optical structure of the internal zoom lens in the first embodiment of the present invention at the Wide-Angle End, Medium-Angle End and Telephoto End; Figure 4A to Figure 4D Shown is a representation diagram of the longitudinal spherical aberration (Longitudinal Spherical Aberration), field curvature (Field Curvature), distortion (Distortion) and lateral chromatic aberration (Lateral Color) of the inner zoom lens at the wide-angle end according to the first embodiment of the present invention; Figure 5A to Figure 5D Shown is the corresponding aberration representation diagram of the internal zoom lens in the first embodiment of the present invention at the middle angle end; and Figure 6A to Figure 6D What is shown is the corresponding aberration diagram of the inner zoo...

no. 2 example

[0061] Please also refer to Figure 7 to Figure 9 , Figure 10A to Figure 10D , Figures 11A to 11D and Figure 12A to Figure 12D . in, Figure 7 to Figure 9 The schematic diagrams of the optical structures of the inner zoom lens located at the Wide-Angle End, the Medium-Angle End and the Telephoto End of the second embodiment of the present invention are respectively shown; Figure 10A to Figure 10D Shown is the representation diagram of the longitudinal spherical aberration (Longitudinal Spherical Aberration), field curvature (Field Curvature), distortion (Distortion) and lateral chromatic aberration (Lateral Color) of the inner zoom lens at the wide-angle end according to the second embodiment of the present invention; Figures 11A to 11D Shown is the corresponding aberration diagram of the internal zoom lens in the second embodiment of the present invention at the middle angle end; and Figure 12A Figures 12D to 12D are corresponding aberration diagrams of the inner z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com