Method for analyzing harmfulness of mechanical assembly process

An assembly process and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inapplicable mechanical assembly process, unclear basis for determining the level, and many subjective factors, etc., to achieve the goal of obtaining Convenience, promotion, close parameters and data effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

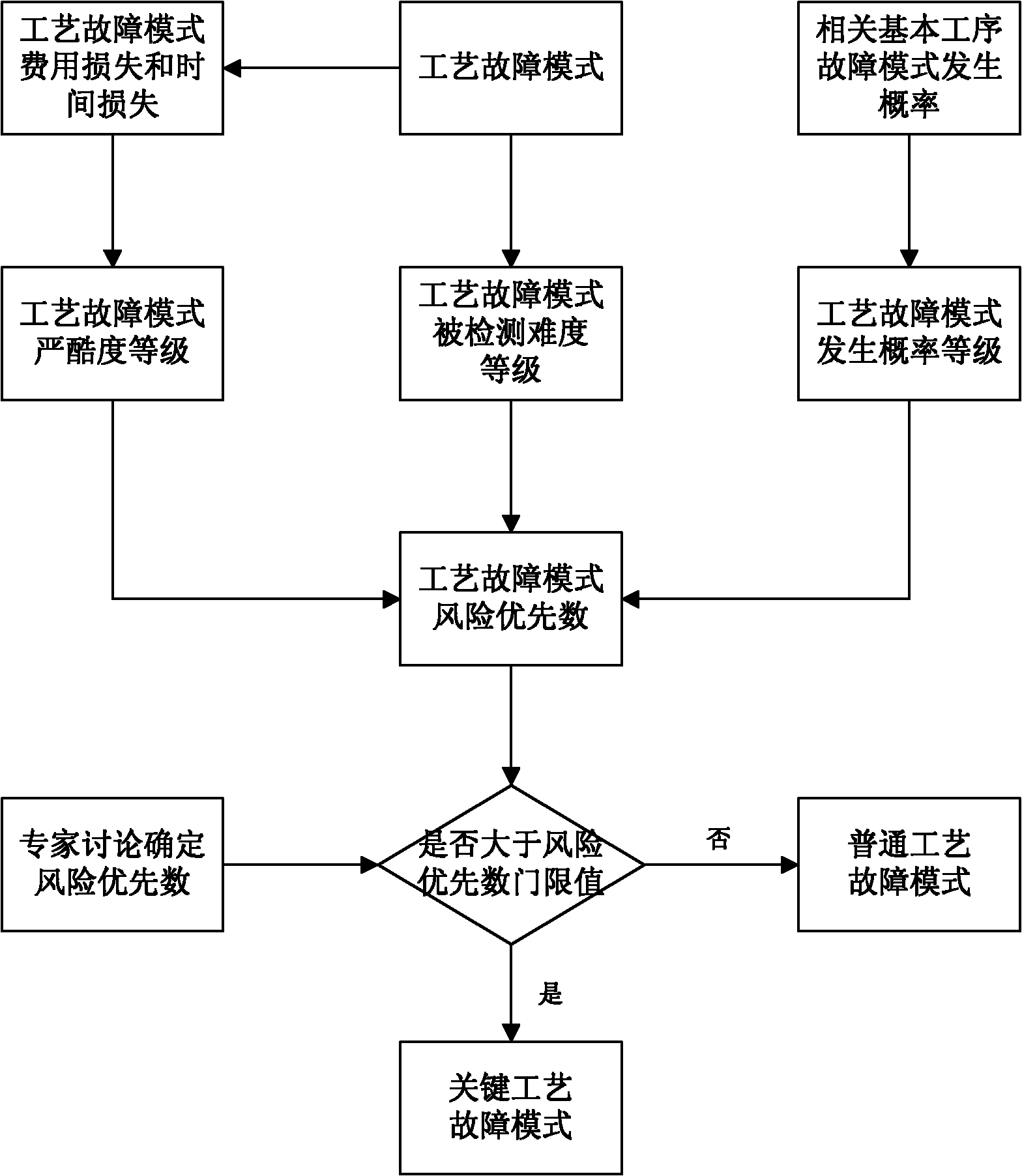

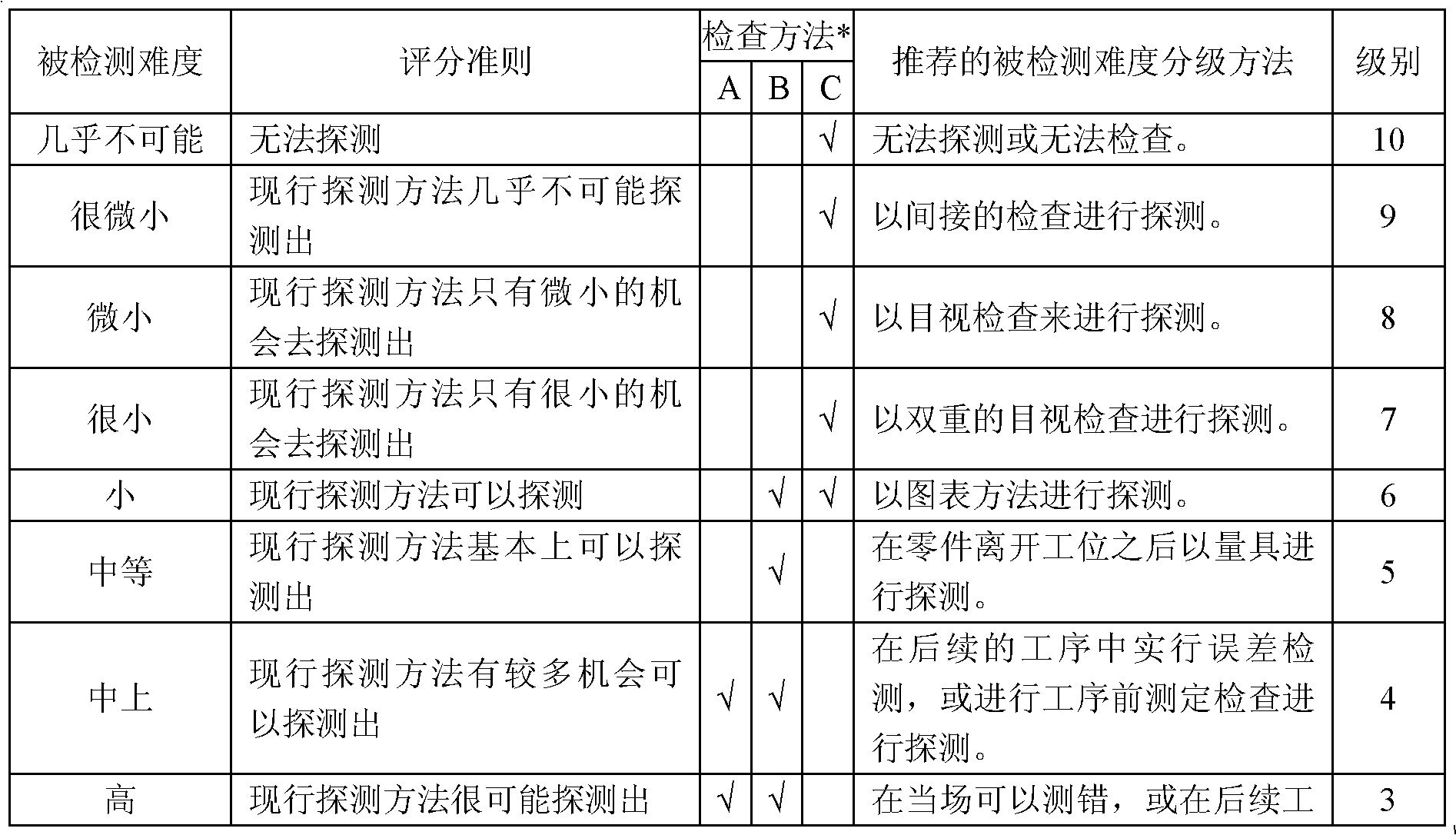

Method used

Image

Examples

Embodiment Construction

[0041] The hazard analysis method based on the characteristics of the mechanical assembly process itself and the application requirements of the present invention will be described in detail below in conjunction with specific implementation cases.

[0042] Case: Applied to hydraulic erection device

[0043] The present invention takes the hydraulic erecting device as an example to illustrate the hazard analysis method based on the characteristics of the mechanical assembly process itself and application requirements.

[0044] First of all, it is necessary to clarify the mechanical assembly process of the hydraulic erecting device, including: parts cleaning, threaded connection with other parts, calibration, adjustment and matching, assembly balance, acceptance, etc.

[0045] The main process failure modes in the mechanical assembly of the hydraulic erecting device determined in the previous work include: cleaning is not clean, residual debris; thread connection is not firm; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com