Process monitoring method and device for trench mos devices

A technology for MOS devices and monitoring devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., and can solve problems such as poor monitoring effect and inability to detect device process drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

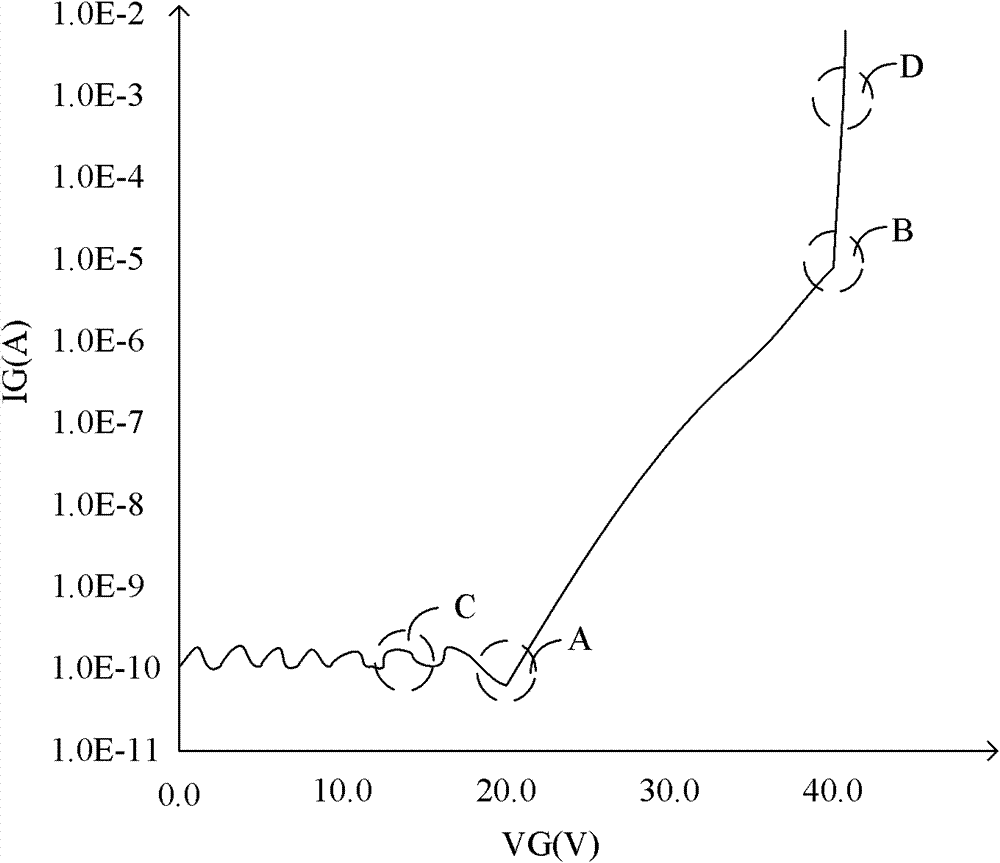

[0032] In the prior art, when monitoring the process of trench MOS devices, the monitoring point is often selected before the soft breakdown point or after the hard breakdown point, and the relationship between the gate voltage and the gate leakage current is not obvious. The process drift of the device may not be detected, and the monitoring effect is poor.

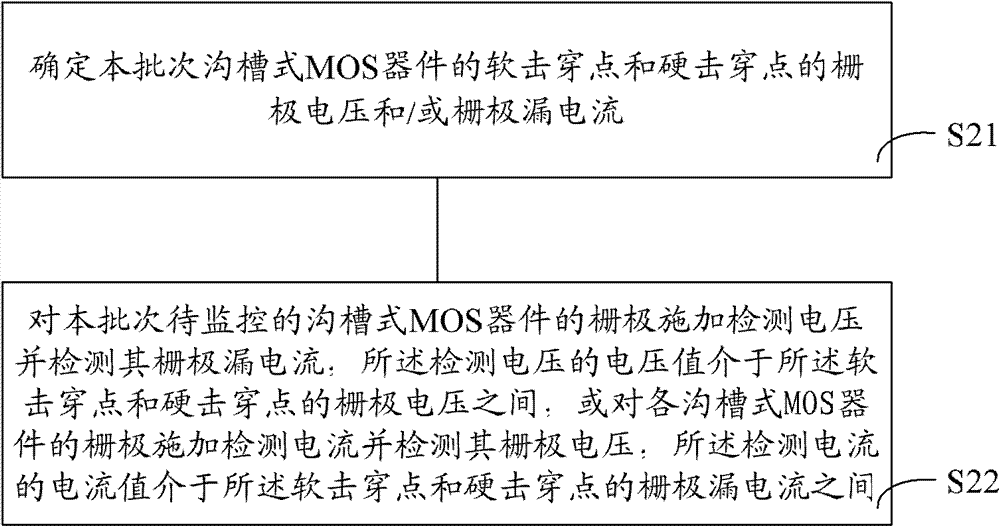

[0033] This technical solution applies a detection voltage to the gate of the trench MOS device to be monitored and detects its gate leakage current, and the voltage value of the detection voltage is between the gate voltage of the soft breakdown point and the hard breakdown point , or apply a detection current to the gate of each trench MOS device and detect its gate voltage, the current value of the detection current is between the gate leakage current at the soft breakdown point and the hard breakdown point . In this technical solution, the monitoring point is selected in the part between the soft breakdown point and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com